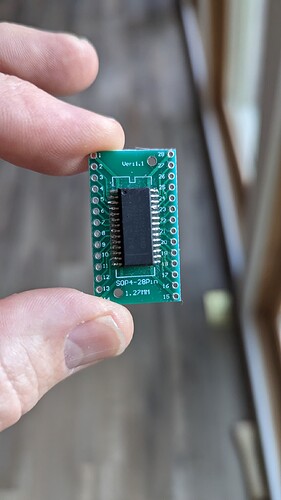

Working on a project that requires 50 surface mount chips to be soldered on to individual boards (see pic). In the past I have used a makeshift “oven” that sort of worked but would get a cold joint every now and then. Was thinking that a heat gun or soldering hot plate specifically designed for this type of thing might be worth the investment. Does anyone have any experience with either of those that can offer some advice? I would rather not drop hundreds on an oven, even though I suspect that would be the best choice.

It’s been several years since I’ve looked in earnest, but a while back there were a number of hacker projects for reflow ovens converted from toaster ovens by adding a relatively inexpensive PID controller, an arduino, and a thermocouple so that the temperature profile for reflow soldering could be programmed. I even saw some based on an electric skillet or griddle at one point, although I’d think that was more wasteful since the heat would just rise up rather than being contained.

Googling “DIY reflow oven” should get you results that capture the state of the art. Looks like someone’s even offering a controller kit where you provide the oven and they provide everything else.

Personally been contemplating DIY reflow oven, and https://www.tequipment.net/Quick/957DW+/Desoldering-Equipment/Rework-Stations that heats and blows air from main controller box, versus the cheaper amzn ones that heat up at the handheld part. I haven’t bought and used, so, am also curious what other people here are happily using too?

“Tweezer soldering iron” seems useful based on my failed attempts to rework/replace SMD components with a regular soldering iron.

I am not an expert. But a hot air station is great at making a mess. Too much flow and stuff flies off. With a chip like that, I would think a hot plate would be the best.

Thanks Tom. The first time I needed to do something like this was a few years ago and all the articles you mentioned sound familiar. I recall that the best solution I found was a cheap amazon oven that needed a bunch of mods to make it suitable for the task. In the end I went with a skillet on a convection plate with fairly accurate temperature control. I put 1/4" of sand in the bottom for even heat distribution and the skillet had a glass cover to make it oven-like and since the cover was glass, I could watch the solder reflow as it happened. That was the makeshift oven I referred to in the original post. Trying to match the solder temperature profile was a bit of a crapshoot, thus the occasional cold solder joint.

Jeff - That’s good feedback. I’ve never used one and based on that testimony, I will likely avoid. I’ve seen some instagram reels that make it look easy, but I’m guessing they are not using a $49 gun from amazon.

I would disagree a bit. I think hot air reflow is what I would use. Get low temp solder to reflow.

Don’t turn the fan speed to 11 or you will blow the chip off, but even the cheapest one I have was good enough to do some small stuff 0805 / SOT23.

That chip is huge and should be pretty easy with hot air

I agree with this. I have had trouble trying to do some rework, when resistors and caps flew off before the flash chip released.

I will say that a hot air gun is useful for some things.

why not order the pcb with mounted smd?

I love doing SMD work. I started building an oven a few times…but got bored waiting on some of the components and just learned to do it by hand…now I’ve had those parts sitting in a box for about 12 years and still haven’t built the oven but have done a lot of SMD boards.

I used to just do it with a normal iron, some fairly fine solder, and if absolutely needed either a jewelers loupe or a cheap desktop magnifier I picked up at Frys for $6 on a whim one day.

That was 30 years ago though…and my eyes aren’t what they used to be ![]()

Now I much prefer some good magnification, and I’m getting better with hot air…but still find a iron to be pretty good for most situations.

The least magnification I’d use is my little clamp on magnifier/light…I love this little guy:

https://a.co/d/bWRZ9Mw

I’m pretty sure it’s the same on Alton Brown used in the last season Good Eats too.

My goto for most things though (not just SMD - I use it for pretty much any board assembly now) is this one:

https://a.co/d/gZJeIG0

Though mine has started flaking out and not holding a solid color temp which is kind of annoying.

These were highly recommended to me by several sources - but I found I really didn’t care for them as the magnifiers weren’t the right width for my eyes so it’s hard to focus through them:

Amazon.com: YOCTOSUN Head Mount Magnifier with 2 Led Professional Jeweler's Loupe Light Bracket and Headband are Interchangeable : Arts, Crafts & Sewing But given how many people recommended them I’m probably just an oddball.

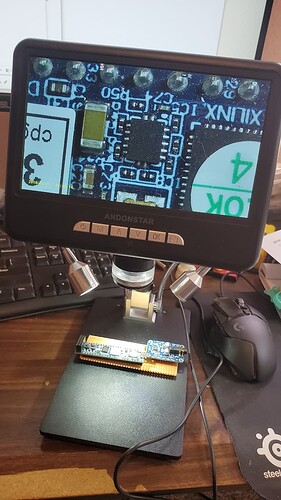

I also have a cheap video magnifier I got off Amazon it’s no longer available but there are lots of them out there:

It’s a HUGE help for both an iron or hot air.

If you’re going to do hot air then don’t cheap out on the solder paste. Get a good brand (I’m partial to MG 860P-35G but have also had good results with Kester EP256) and I like it in a syringe. I also got an assortment of Luer lock tips in various sizes off aliexpress for a few bucks…easier to pitch them than try to clean them.

Having a syringe of good quality flux can also help a LOT.

If you have a stencil then paste in a tub can work but I usually don’t have the benefit of a stencil on my projects. It takes a little experimentation but with the right size tip dispensing the right amount manually isn’t that hard. On chips like yours you can just lay a strip of paste right across each side…and for passives a little dab on each pad is fairly easy.

Keeping the speed lower on the hot air combined with the stickiness of the paste tends to keep parts in place…but you can still have small passives tombstone on you if one side gets hot quicker. I find a larger tip on the hot air is generally easier unless you’re doing rework and don’t want to affect already soldered bits.

Honestly though on a chip like that I’d probably just do it with my iron. I don’t even like a super fine tip for most SMD. I love my pinecil iron and with a cutoff conical tip it’s easy to turn it to get a small contact area…but the bigger tip holds more heat making it easy to make quick joints. Just put some flux down to hold the part in place and help…then tack opposing pins at each end first. Check that it’s aligned…then you can either do a quick tap on each pin or do a drag solder and let the flux do the work. I’ve never got the knack of the drag solder…but I can tap out those pins really quickly so it doesn’t bother me.

I also do a lot of sms soldering and prefer the iron but Stoli had to do 50 chips with each 28 pins

I went the diy reflow oven route to support my sons SMD projects. Picked up a used toaster oven from goodwill for $15.

It uses an ESP32 with k-type themocouple input and ssr output. It has a small oled display, a buzzer, and 2 buttons (start/stop).

Other than the oven I had everything in the junk drawer except the max6675 thermocouple breakout (2 for $10).

Code is messy and immature, but it works well enough with the default heating profile that I haven’t messed with it since it went online. It has the foundation for several selectable solder compound profiles and hosts a web page that shows the target and actual temperature charts. The web page doesn’t ever get used so I didn’t finish developing it, but does have bi-directional communication via web sockets.

If I knew how much he was going to use it I would have I would probably have invested in one of the more mature projects / kits but I thought we were in for a one-off fail or loss-of-interest folly. Turns out he is pretty into this stuff.