Hello everyone, welcome to the humble beginnings of my journey to finally having my own chip-making robot!

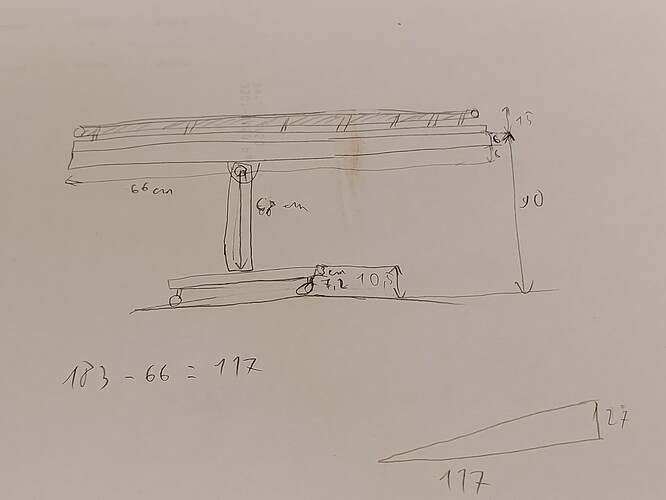

I’m currently in the “coming up with a table” stage of the build.

Laura will be living in a detached two car garage so the table needs to resist quite high moisture and temperature variations, which is why I’m not using natural wood for the frame.

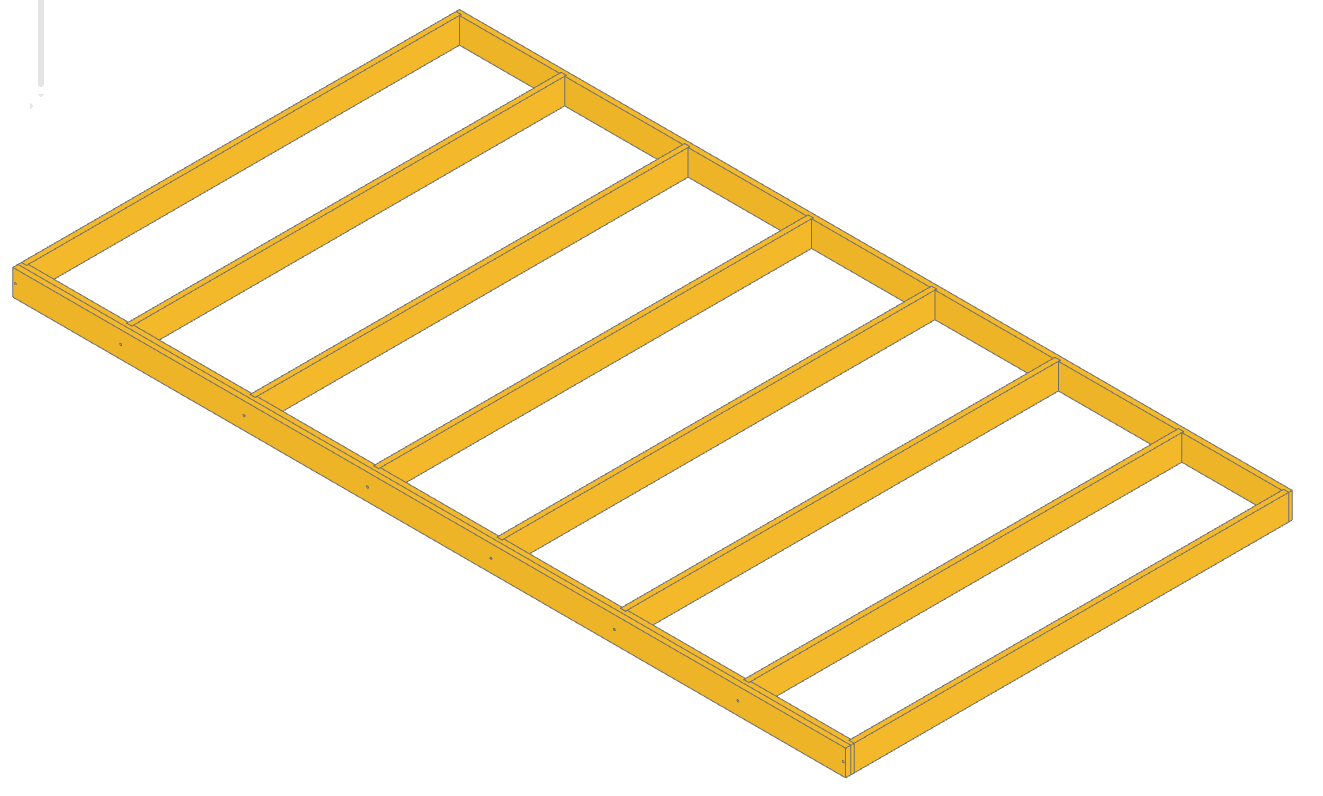

I’m not planning on a full torsion table build, as these require either a large flat reference surface or are very annoying to cut.

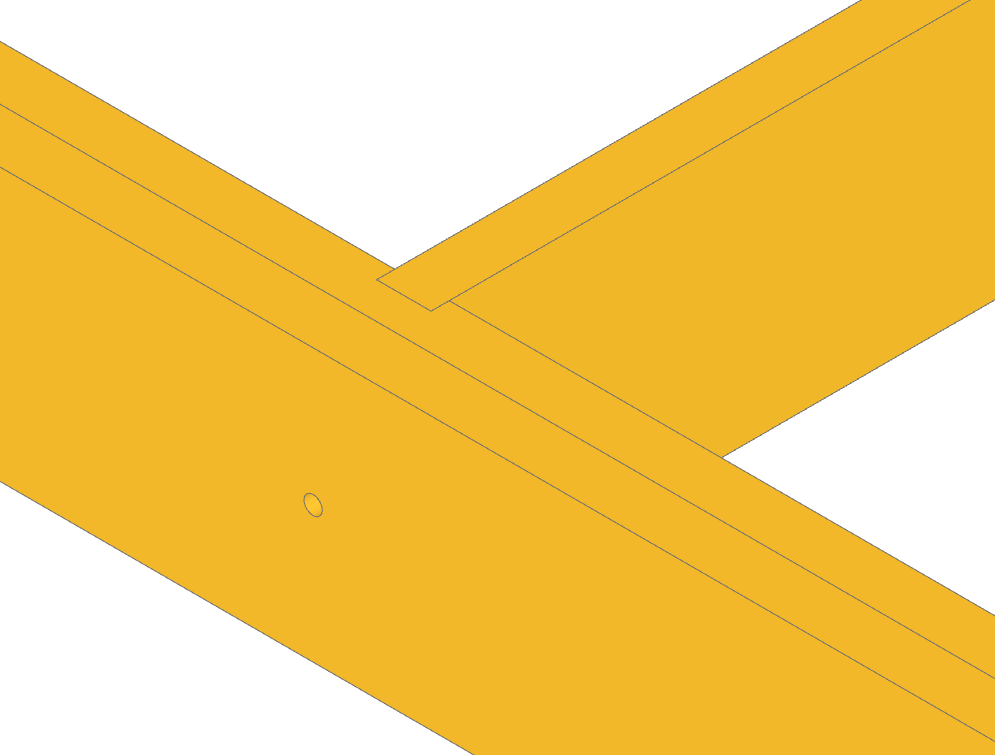

The single screw hole will probably turn out to be two screws and a lot of wood glue.

I can get the beams very straight on one side by running my tracksaw along them after gluing them.

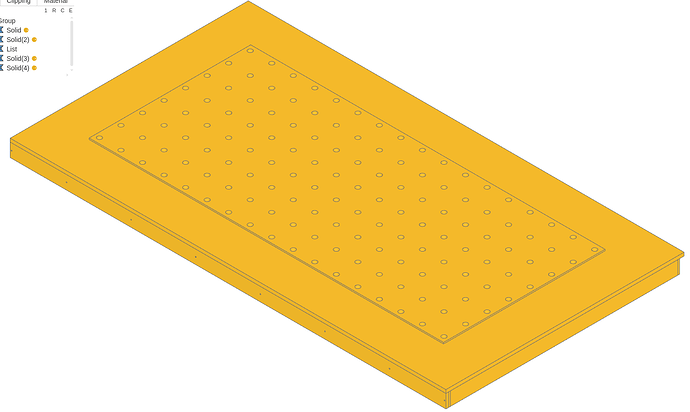

The tabletop will be a 15mm OSB sheet with an MDF spoilboard on top and 20mm dogholes in the same spacing as an MFT.

These will be partially cut by Laura herself, and potentially finished with a templating endmill by hand. Since she will be getting raised rails to ride on, I’m not keen on installing an endmill long enough to cut through the entire table!

The targetet workind width is around 700mm (not yet fully decided) or maybe up to ~830 so a proper desks tabletop can fit on her.

Laura is going to be mostly cutting and engraving wood with some acrylic and even less frequently aluminium.

If everything goes the plan she’s going to be building me and the wife a new kitchen after all (we are taking over both floors of the house where living in and will still have a functioning kitchen)

As you can see, at the current point it’s more of a design log, but I gotta infodump on people that find this stuff as cool as I do before I start annoying my entire real-life social circle…

Off to do more CAD and try to figure out the offsets between working area and table, the calculator after all only gives total table size.