I would guess it’s probably fine. Your 5V regulator would be the first to go, since you were shorting to ground. But the rambos are pretty tough. You were smart to turn it off, but when it’s dry I bet it fires right back up.

It’s alive! Thank goodness! Thank you all for your prayers of support. Hahahah

Now, I better get this Rambo a raincoat…

Conformal coating? I have an aerosol can of it, cool in the quad copter days with wet lawns. I think the heat is okay with that stuff.

Can’t you just switch to dry ice?

Added benefit is you can’t start the machine on fire!

Hahaha. I wonder how long a chunk of dry ice would last if left to ‘melt’?

I bought a few ammo cases (plastic waterproof kind) to house the power supplies and controllers for my Christmas lights. I think I’ll use something similar for the Rambo. And the spindle power supply and controller I guess. It’ll also be a good opportunity to lock down the wiring and maybe redo the z probe connectors.

The lego advent calendar almost got Kelly perfectly. I think there’s something wrong about the chainsaw though.

Haha…that dude must have been building an ice slide - that’s the only time we use brooms like that.

Spoiler

It’s for curling, I’m pretty sure. We still have 19 boxes left.

I don’t know…it could be a garden gate and some sort of harvester…maybe it’ll be a winter garden scene where you can harvest magical icicles and Elsa and Anna will materialize in some frosty holographic mist.

Lego can do that you know…

we got my kids the same calendar this year.

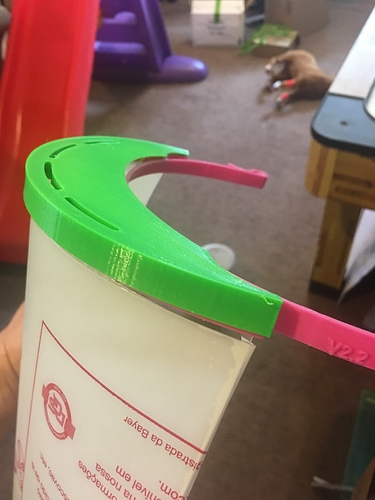

It’s been a while since I’ve posted much in this thread and I’m sure I’m not the only one here doing this at the moment. I’m posting it here for safe keeping so that three years from now when I’ve forgotten all about this thing called Covid I can remember the time I reached out to the maker community in my area (one of them a fellow MPCNC’er) to help me 3D print 240 of these face shields.

Awesome work!

Some more surfacing happening today. I haven’t had the drop section out of this table in a LONG time. Four of these to surface. Bottoms then tops. Two are 30cm dia, two are 45cm dia.

Yes! That is awesome. I love the clamp strap.

That pig looks like they forgot the safe word!

Hahaha. Does indeed.

The other two logs are quite green still and I think they were Douglas Fir because they are holy hell heavy. How does one flip a heavy carving in a drop table MPCNC? You hop right on into the machine!

One pair of perfectly flattened (top and bottom) Bear side tables ready for delivery. Owl side tables will be finished surfacing in 30 min.

Just to clarify… you hand-carved the bears and then just used the MPCNC to flatten the tops?

Otherwise… I’d really like to see how large the rotary access is and the length of the bit that did the bear carve

Those look really nice.

Ha! Sometimes I wish I could do the rough outs with the CNC and then just finish up with the saws but that would suck the fun out of it completely. Or would it?

You are correct - I only used the MPCNC to machine the bottoms and tops so everything was perfectly flat.