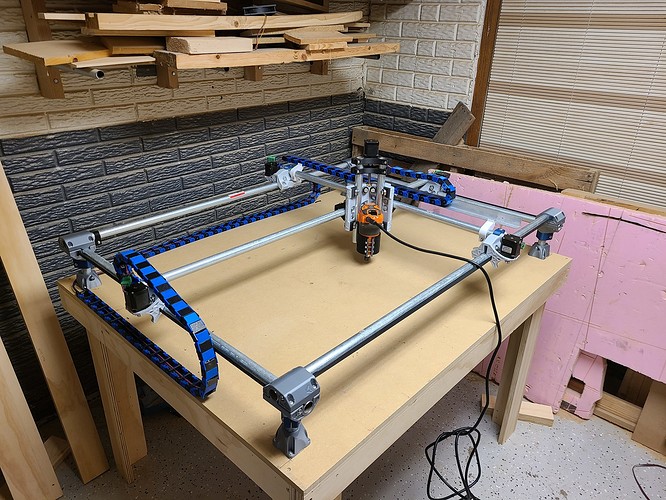

This is just a gripe. Drag chains are too expensive for what they are and take too long to print. Even from AliExpress it costs as much as from Amazon by the time shipping is calculated. I just want something easy that I can use for cable management and make my MPCNC look pretty.

I’ve seen several topics on the “tape measure trick” in the last year where PET sleeving is combined with the metal from a tape measure to create a cable-chain-like movement. Here is one example topic. I’ve also seen builds that just use the PET sleeving and tack one end down to the table. If your table is a tight fit to the legs, I’ve seen sleeving just hanging off the side of the table…looks and works fine.

I did the tape measure on my lowrider and didn’t really like it. And I dont want to leave sleving hanging because everything else in my shop is mobile and has grabby hands.

I agree. Drag chains are expensive for what they are… But when they’re the right solution, they’re the right solution, so I have them on my MPCNC. Probably though I spent way too much for the slotted angle (cheapest angle of appropriate size) that is supporting the drag chain too. It’s always the ancillaries that rack up project cost.

They are the right tool so I’ll be getting some. Just might have to either wait for a little while to purchase or deal with the 8 hours for 15 links printing times.

They do look good! Which ones did you get? I’m also considering cutting the power cord on my router and running AC through the drag chain as well, I saw another build with an XT60 connector to have a removable tool. I’ll have to find the appropriate gauge stranded wire for the job.

We have seen a few problems with electrical interference with endstops. If you have endstops, you might want to consider shielding when you made the mod.

I second what Robert mentioned… running your router power line in the chain will induce a lot of noise on your endstop wires. Shielding and filtering can help prevent problems if you go this route. What I did was make some custom clips that hold my router power line about 2” away from the chain… the clips attach to the chain links. I also have input filtering with Schmitt triggers to stop false endstop triggers.

Also, I think an xt60 is designed in a way that may well turn out safe with 120vac, but they are not rated/tested for it. So be careful using them like that. As an alternative, there are a lot of other 120v rated connectors you could use instead. Here is one example:

Also, instead of buying some strand for this, if it is long enough you can just reuse the existing power cord that you cut off. If it is a good brand router, chances are it has really good cable already.

My guess is that the heat wouldn’t hurt the xt60. But the distance between the contacts (in air) may not be enough. It may be enough normally, but if something goes wrong (like maybe unplugging a running router may spike the voltage), they may fail by arching.

Another danger is there isn’t much handle to grab onto and your fingers would be pulling on very small insulation over AC. No thanks.

Awesome feedback, thanks guys! I’ll consider a more appropriate connector and shielding considerations.

I don’t run end stops. I have spacers that set my axes square. I still haven’t cut the power cable and run it, either.

@NickM I 3D printed my own chains.

I’ve 3d printed some before. Took a long time to print and eventually they warped. I bought the bullet and purchased some from Amazon. I got the open type as it’s a pain in the ass to push cables

I printed all of them. Took a couple of days because I could only print 15 at a time. They’ve lasted great out in my shop for over a year now. No warpage or anything. I think I printed them in PETG.

They are the open style because I also hate trying to push cables.

Are you using a Ridgid trim router as a spindle? How is it working for you?

I was using it. OK to use. I was having issues keeping the bit loaded. I switched over to a Makita a few months ago and really like that one better. The Rigid is now my circle jig router.

Okay cool thank you, I will look at the Makita.