That’s what I don’t get. What changed to make anything overloaded? Its been running for months now fine with the current config. No USB cables since its all canbus and the CB1 is mounted directly on the M8P. Only thing I can figure is something in the newest Klipper update added something. Unless it was something in the Orca update that changed things in the gcode maybe. I am about to start some test prints for a new filament so we will see how that goes and if I get any more errors.

You are good! Ill take any help I can get!!

All of that is good. Canbus is a twisted pair and set up with 120 resistors on each end. All of that has been working well.

One thing I found was microsteps set too high can cause it too. And my extruder is set at 32. Its the EBB36 that’s tripping the timer too close, and that has the 2209 for the extruder on it. Thinking about dropping that down to 16 and see what it does.

The 2209s will interpolate between microsteps. So sending it 1/16th and letting it interpolate to 1/256 is the way to go. You don’t need 1/32nd.

You probably know this. But that is klipper saying it can’t sync the clocks between two mcus. It wants fast timing.

I don’t know how the CAN works exactly in klipper, but CAN is a priority based protocol. If one “babbling idiot” (a technical term) sends too many messages, the rest don’t get through. And it isn’t full duplex. So if the bus is full of high priority messages, then others can’t get through. That kind of thing really looks random, because it is just based on how the timings work out sometimes.

I should go look deeper at the CAN in klipper. I wonder how they are organizing priorities.

Yeah. It was set that way in the Orbiter config and I just left it. Now it has been changed back to 1/16. I need to see if it has interpolate: true set

Yeah that’s what I was assuming it meant. But I have no idea how to tell what was causing it. It seems to be better now. No more errors since the other night.

Well I thought I had it fixed but seems I am still fighting timer too close issues on my V5. 2 days ago I disabled gcode_arcs in both klipper and orca. After that no more timer to close issues. Then last night I updated klipper hoping to fix my z offset issue and now my timer too close issues are back. But its odd. Its every other print. I get a timer too close, restart, and it will print fine. then the next print ill get a timer too close. But now the timer to close is coming before it even finishes homing. I have watched the load meters in mainsail and it never goes over 20% on the CB1 CPU so I am not understanding why its shutting down.

I made a post on the klipper forum but not having any luck getting any help with it yet. Just updated it so maybe now someone will respond.

All your microstepping is set to 16 now?

Yes. The only one that was ever at 32 was the Orbiter. That was how they had it in the config and I originally left it alone. Now I have it set at 16 as well

why 16?

Cuts the amount of steps the Pi/CB1 has to calculate in half. Then the stepper will interpolate up to 256

quaternary

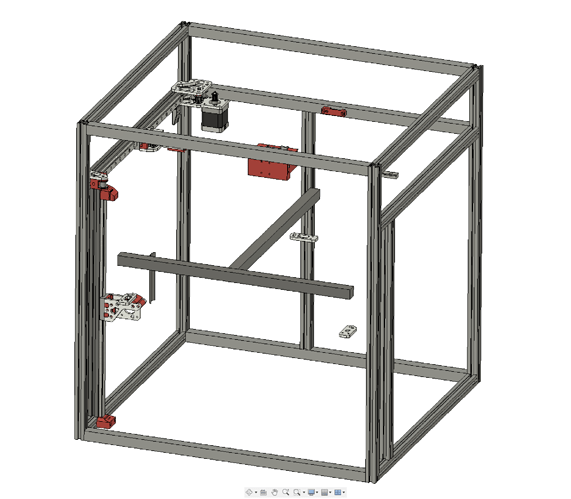

damn i need to build one of these and get an old oven off marketplace and powdergun… all the things. nice build.

if anyone reads this by chance i tried to change the parameters in the fusion file to make it a 400^3 build volume and it didn’t work the bed and the x gantry disappeared in the model. maybe i’m doing something wrong.

I got my Powder Coating setup from Harbor Freight. Wasn’t bad at all. But I am sure you can find one cheaper on Marketplace. Where someone bought it to use it one time and didn’t need it anymore.

I downloaded a fresh version today and tried it. I’m not sure why but it does some funky things to the model. I didn’t have any problems when I did it for my size.

I can get you all of the extrusion lengths from this model and the rail lengths. That will be most of what you need. And if you want a 400mmx400mm bed that will fit no problem as long as you have no reason to have the nozzle go past the edge of the bed anywhere.

the bed plate mounts also change slightly when the parameters change, so those need to be exported as well

@Michael_Melancon If I understood him correctly he was looking for the drawing for the bed but I cant seem to find it either, or remember where it was in there LOL. Been too long now

the screenshot you posted is what i got too… yeah this is definitely something i will need but probably not for at least a few months so no worries. i have a rat rig vcore4 on the way atm. so that first. but it seems like a good idea to have 2 klipper corexy units running smoothly eventually… then i can relegate my enders to basics and backup/workhorse duty. i considered making a 500^3 version of the mp3dp too but i’m seeing that is probably not worth it generally speaking (just because of the increase in reliability issues no matter what the printer as you go up in size) unless i have a specific use case which i don’t at this moment.