Only reason I do is to easily get at the memory card.

My jackpot is near the center, too.

Even if I put the controller to one side, lile.my LR3, the drag chain mounts near the center, or else I would.have needed a longer drag chain for the LR3. A simple wire loom will do to get the wires there because the center is the closest place that needs to flex in.order.to cover the whole span.

Not needing wire extensions is nice.

I also put it at the side to have access to the SD memory card. I added the needed extensions to do so. I figure, I only had to create the extensions once. Custom creating them meant they could be pretty much the perfect length.

How often do you have to pull the SD card? I don’t think I ever have.

I suppose that’s only if your CAM is out of wifi range from the controller, or on a different network (AP vs. STA)?

I used to have to pull mine a lot. But since somewhere around 3.7.16 or so I haven’t pulled it a single time. Sooooo much easier uploading over wifi lol

Every job. My wifi is spotty in the shop. My design computer is not in range of the AP.

I’m no where near the technical expertise as you guys but I load the files onto an SD card every time. Design computer is in my bedroom, lowrider 2 with a ramps board in the garage. I’m walking to watch the CNC machine anyways, why risk something going wrong over wifi. I do use the cncjs raspberry pi image to control a dkjlinux inspire laser engraver but I’m a little more willing to walk around while that is running.

Pretty sure somewhere else on this forum Jeffe mentioned that a lot users are using SD card but aren’t present on the forums as much. Maybe, if I’m remembering correctly

As few times as I can possibly manage.

Put the SD card in, manage the contents via wifi as much as possible. My CAD computer is on a different floor, so sneakernet is a pain when you go back to the machine and forget the card upstairs. Then there’s the fun game of “which card is it anyway?” When I put the 32G Sandisk card down in a pile of other 32G Sandisk cards used for various things, practically none of which are labelled (The MP3DPv3 still needs sneakernet.)

So I hope not to need much access to the SD card slot.

Since they fixed the uploading bug with 3.8 I haven’t transferred files any other way but wifi.

I have always transferred via wifi, never had a problem, but my projects are small. Also, i saw the problem some were having with cards. I never thought about it, but I have a microsd to Sd converter plugged in and a 16gb sd card I got from Ryan on my last purchase (was a while ago) So it is a slower more reliable medium!

But yeah, back to point, always have transferred via wifi.

Best money I ever spent. Not a single slow down spot anywhere in my house or garage!

I can 1000% relate to this! One of the reason I was so happy they fixed the wifi transfer! Has been amazing!!!

Just FYI for the holiday weekend I’ll be online but I won’t be able to work on any physical experiments. When I get back Tuesday I’ll be ready to start printing RC-N or doing more experiments.

Cheers ![]()

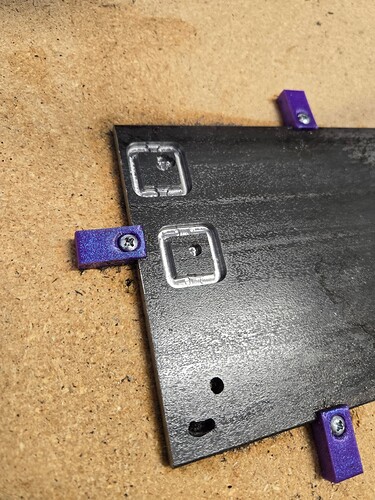

For a variety of reasons, I have pulled mine quite often. It’s one reason I put my Jackpot on the edge for access.

I was trying some practice cuts in steel, in preparation for attempting a steel XZ plate.

It went okay a couple times, and then it suddenly got much worse, spitting sparks like crazy.

I’d say it’s time for a new bit:

Neat. Using Air or water/IPA misting? Looking forward to more metal with narrower gantry LR4, have been digging through Jonathan’s posts for mist setup info/link. Hmm, another reason to conformal coat controller, or place outside the beam?

No IPA mist for steel, sparks plush vaporized alcohol is no good!

That is exciting!!

Last time I tried it I used a two flute. I would say, unsolicited advice, biggest shank possible, flutes as short as possible to clear your material, air, plus some sort of mist lube would be awesome.

Here’s dad to spoil all the fun… ![]()

Dude that is AWESOME!!! I have yet to attempt steel. Too afraid ill have to take out a second mortgage to buy enough bits LOL.