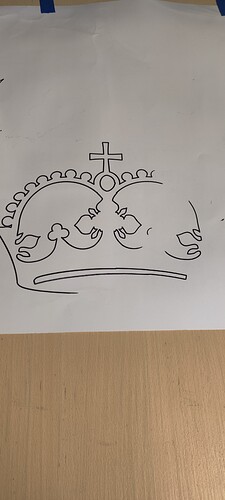

Whoo test crown but right side bit high needs adjustments but can’t post video but here’s YouTube link at …

One thing about dual z leveling isn’t perfect it should auto levels but one side starts to jumping while other side still not reaching to end stop…

Sounds like the Z end stops are reversed between Z1 and Z2

No both rotate perfect and I checked info z2 goes to Xmax end stop and z1 goes to Zmax stop

Z1 is on the right side

Try triggering the stops with your fingers. Make sure that the motor on the side you trigger is the one that stops.

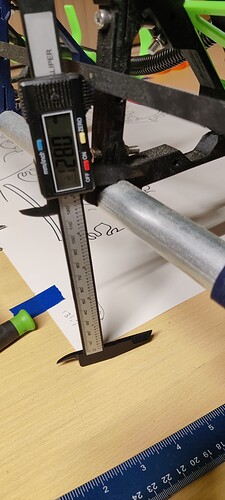

Hmmm mislabeled both end stops so flipped and it works but still not perfect I measured both sides after z homing is 1.9 mm off

It should levels twice not once …

Have you done the leveling step in the docs yet? If not thats where you can fix that in software so it will home then adjust level.

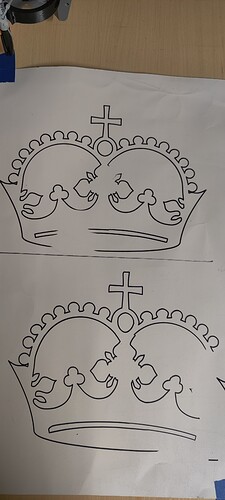

2nd test 1.9 mm off

Top 3rd test table not real flat need to put mdf scarfical board and mill it flat

Note bottom was the first print

I’m thinking might add one screw to one side endstop adjustment for rail offset that might correct it

Look up the M666 command. That’s about where mine ended up as well just with how the table was built, so I have a 1.6mm “pull off” on one side for the Z axis, so it’s level when I home it.

Also, the Z end stop positions are somewhat adjustable, you could probably get it closer before needing the adjustment.

Congrats on the crown!

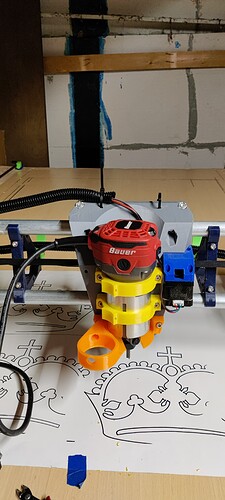

Finally got a hold of Bauer router from harbor freight tool clearance shelf $31 I verified fits those Makita 700 brackets perfect fit u know it’s a clone of Makita brand? Will mount it later this evening

Perfect fit and bit is square to table yup makita700 brackets compatible with harbor freight tool Bauer router

Nice! Yes, I think it’s a clone.