Have to do some wiring stuff tonight maybe.

After playing around with the conduit rails off, the motors still “tick” on my fingers…but I think that’s just me feeling the steps with some sensitivity. Looking at the pulleys, they don’t stutter or anything visibly, under load or otherwise. Everything looked very smooth without the middle rails and Z axis on.

So, either this is the wiring issue that @SteveC mentioned, something to do with my inner conduit rail, or something to do with the whole middles assembly.

What I am mainly seeing in the “stutter” now, appears to be the X side of the middle assembly slagging behind and then catching up. Maybe it’s not as square as I think it is? Or the middle conduit possibly bent slightly but not enough for me to see. A jacked up bearing possibly? Though I like to run ~200mm back and forth on X direction and try to keep my finger on the each bearing for a full rotation or two just to see if there’s any tiny nicks or wobbles or anything “odd”. But they seem to roll really well.

One thing I asked previously, either in this thread or another one. Realistically, how tight should the bearings be to the conduit? IE: Should I be able to spin them ever so lightly without it forcing the whole axis to move? Or when I try to roll them with my fingers, it grips enough to start pushing the whole thing?

Kinda same question goes for the roller large washers. Should they be so tight they don’t spin by hand? Or should you be able to spin them a little/a lot?

I don’t think I have enough pipe to cut another X middle rail to see if a new rail fixes it, and since my machine isn’t a square design (roughly 24x36-ish), I can’t just swap the middle rails to see if it starts happening on the other axis.

Ooh…final question…does it matter which direction the Z axis is pointed in relation to X0 Y0?

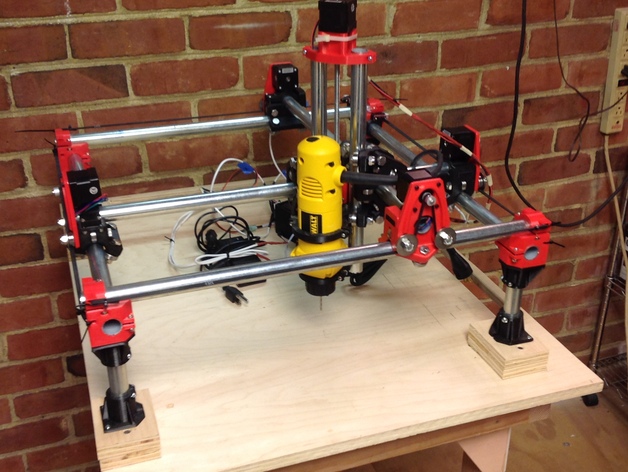

The thingiverse picture kinda has the machine at a diagonal, so I’m not entirely sure which is X and which is Y.

If the left hand (not pictured) corner block would be 0,0 - then that’s how mine is.

If the lowest corner is 0,0, then the tool is pointed in and towards 0,0 - then maybe I need to turn my assembly around.