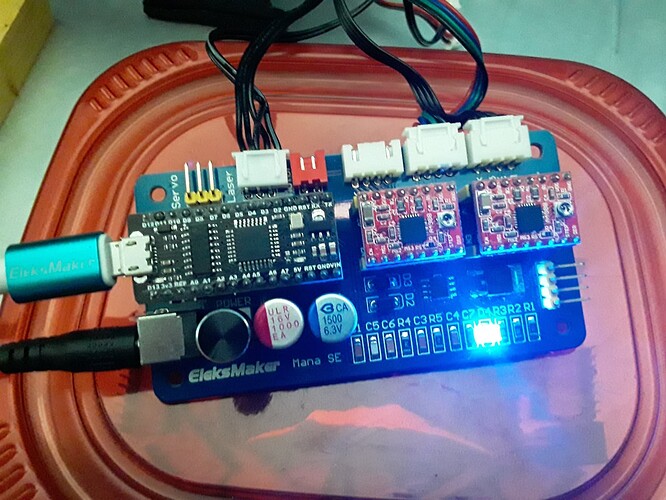

Noting a detail from @dkj4linux original thread about the JL1 Here:

He was able to use a cheapo controller and there is detail on how he connected the laser module shown in this picture from that thread. (He didn’t use limit switches nor the crosshair pointer. )

This is great detail and I’m appreciative of his taking the time to document it.

Using the orientation of that connector on the “Laser” header on the board, I’ll have an easier time mapping things out. Still mining his thread for additional details. Good stuff!

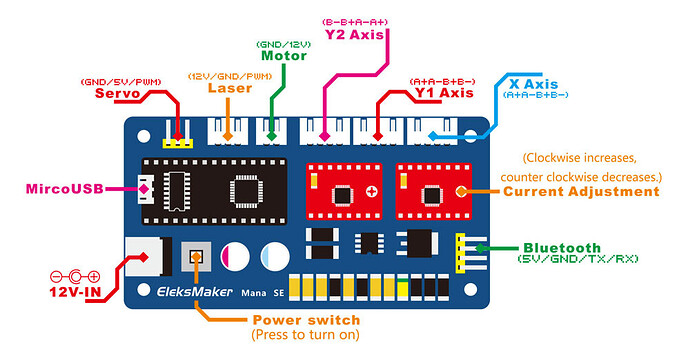

Editing to add the wiring guide for the Mana SE board shown above. This will help me (and maybe others) when interpreting the wiring shown above.

Looks like the far left is +12V (motor/board inlet power), then GND, and then PWM. This makes sense as the 4th position in the JL1 connector goes to a limit switch, and that limit switch uses the GND as well, which is why the JL1 harness has two wires in the 2nd position from left on the “LASER” connector.