Hi everyone, unfortunately, I’m back with more questions. I have searched the internet but I think my novice level needs some feedback. I’m not sure what direction to go but any help would be greatly appreciated.

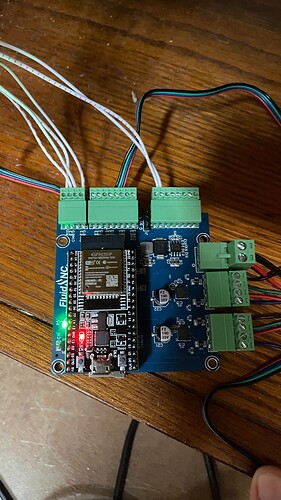

Hardware I’m using: FluidNC Pen/Laser CNC Controller TMC2209 along with optical endstops (I have not added an SD card yet).

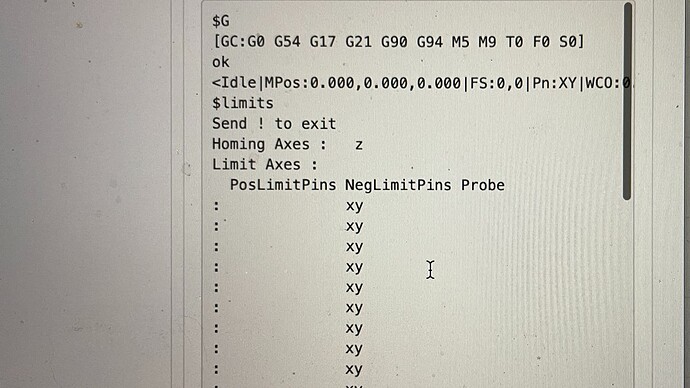

I wired everything up and I have consistent movement from the webui commands moving around the table. I can manually trigger the X axis end stop and it lights up and goes away. However, the Y axis endstop is consistently lit up and I cannot have it stop being triggered. I will post a picture of my wiring. Do I have a faulty endstop? I keep getting error messages saying “Not a homed axis” or “No homing cycle has been defined”. When I send the $limits command, I get pn:xy and neg limits pin tripping the entire time. I read on the V1 forum somewhere that with the optical endstops they have to have the GPIO pin set high as opposed to the default low. Is this my issue?

What should I do?

- Do I need to download additional files from Fluidnc or the installer after purchasing it from the shop? I was hesitant to do so only because it plugged and played right out of the box.

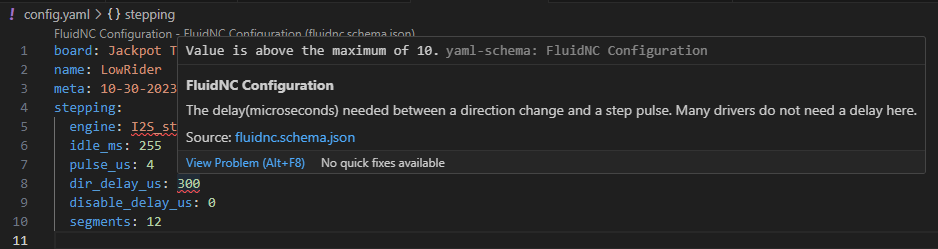

- Do I need to edit the yaml file and adjust the gpio settings? I am struggling with this because it’s my first time using fluidnc so I couldn’t figure out how to edit/access the yaml file. This might be due to #1 that I haven’t installed anything additional.

- I also read somewhere that someone was having issues and it was due to not having the kinematics group at the top level. When I access the fluidnc webui, I don’t see this listed anywhere. If this is my issue can someone tell me how to add this?

- Looking at the $limits command, I see that homing axes: Z and limit axes is blank. Is this the culprit? How do I adjust these?

I realize that these issues are pretty broad and I’m happy to share any additional information. I just don’t know what I should try next. Thanks again.

This is what I get running the limits command: