What are you using for creating your G-code, and what controller are you using on your lowrider?

G94 and M62 are not actual Marlin commands. G92 is a valid Marlin command, but perhaps there is an extra space in the syntax? Not sure if any of them are valid or not in FluidNC.

Jackpot controller I got the program right off the v1e instruction page

And what CAM program are you using?

Estlcam

I’m very new to this so I might ask a lot of questions

There are two things to understand about EstlCAM.

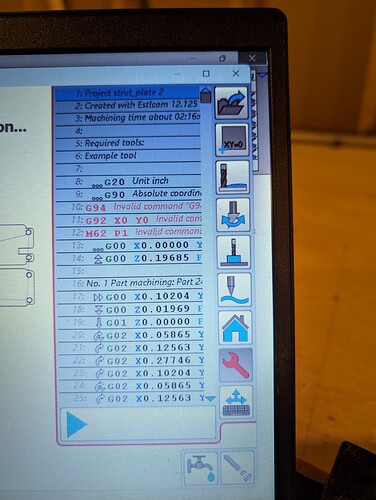

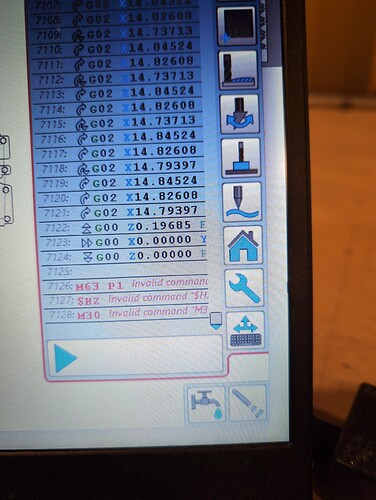

One is that EstlCAM has both CAM and CNC functions. The CNC function won’t work with either SKR or Jackpot boards. From your screen capture, it seems that you are trying to use the CNC function. Instead, use EstlCAM to create the gcode only (CAM function), then use a different method to send the gcode to the Jackpot board.

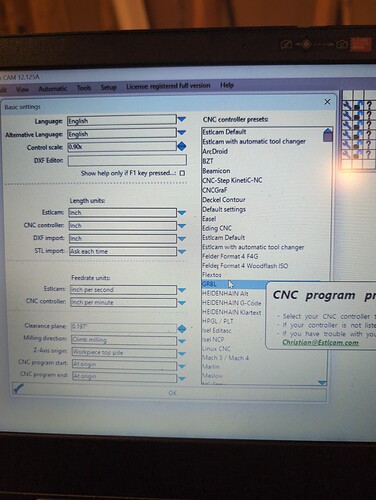

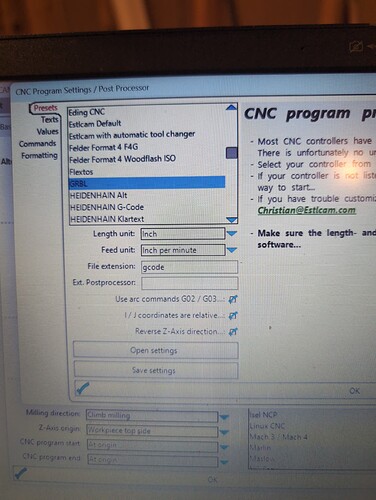

The second thing to know about EstlCAM is that you need to specify the correct controller in the CAM section setup (Setup - Basic Settings - CNC Controller Presets - GRBL)

Hope that helps

No worries. We’ve all been there ourselves,

Ask away! We’re all happy to help in any way that we can.

The first picture is from the CAM function, which is what you need to set up. It appears that you have set the controller settings correctly.

You may want to change all of the units to mm/min and mm, rather than inches/second, Inches/min and inches, as that is the common language used on this forum, and will make future troubleshooting and help requests easier for all concerned.

Also you may want to increase your Clearance Plane to avoid hitting hold-down screws/clamps/etc. I use at least 6mm, others go as much as 10mm.

Lastly you have the Control Scale set to 0.90, that should be set to 1.00, otherwise the CAM will scale all of your designs to a smaller size than originally designed.

The second picture is from the CNC function, which cannot be used with the controller that you have, so there is no need to set up that section.

Ok next question do I need to use a touch plate

The touch plate is a convenient way to set the Z axis to zero (mm) at the exact location where the endmill (router bit) first touches the top of the work surface (stock). This is done using the Probe Z command (G38.2 Z0 in Marlin world), and then setting the Z location using G92 Z0.5 (the V1 probe is 0.5mm thick, so Zx where x = probe thickness). I’m still living firmly in Marlin world, I think that the Jackpot/FluidNC/GRBL process/commands may differ slightly.

There are other ways to accomplish the same objective. One way would be to manually lower the Z axis until it just touches the top of the stock (use a piece of paper, similar to setting the Z offset on a 3D printer).

So to answer your question, do you need it? No, it is not essential, but it could make your life easier, and most people here use one. Note that you can make one out of any metallic plate, an alligator clip and a couple of wires, or you can buy one from Ryan.

@elyama - If you find any comments useful or informative, (on this or any other thread), don’t forget to use the “like” button to leave an emoji on that post. It helps other users to gauge the quality of the reply, and provides some nice feedback to the person who posted the reply.

Also if your original question is answered clearly in a particular reply, you can select that post as a “Solution” . This helps to identify the correct answer to other users that may have the same issue.

Any idea where I can find some tutorials or more info on using the jackpot controller

I’m probably the wrong person to ask about this, as I am using the SKR Pro V1.2 controller. Others may be able to give you a better answer, but you should probably start a new thread for that.

There is some good basic information in the V1 Docs. I would suggest reading all of the pertinent sections of the Control, Tools and Learn sections.

From there, use the various sections to manually move the Lowrider in different directions, draw a “crown”, and cut a few basic test shapes in something easy like styrofoam.

Once you have worked your way through that, you should have a better understanding of the overall process. From there, if you have any specific questions about anything, then create a new thread to ask for help. It is better to create a new thread for each question, rather than asking a second question after the first question has been answered,. This helps other users search for answers on similar issues that they may be experiencing.

Best of luck on your CNC journey!