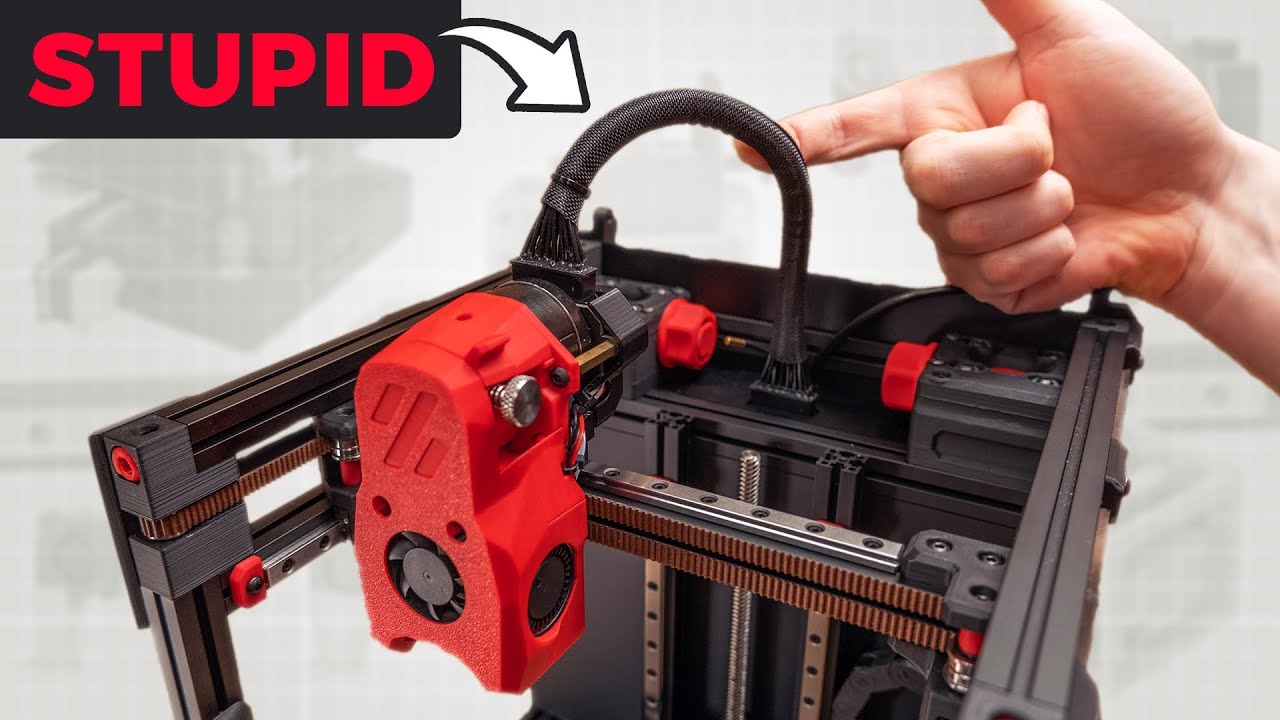

You need wires, they need to be bundled in some way. My solution has always been to mount them as close the the center of the rail as possible. Mounting them at the highest point is just like people mounting a vacuum hose 3’ up on a rigid extension on our CNC’s (not the same as suspending a hose).

It has always seemed obvious to me but judging by how many people mount wires at the tippy top and stack things tall like a fancy chef…and add vacuum extensions it must not be very obvious.

tldr;

fit and finish of the x trolley was the problem. preloaded rail made a huge difference and the rest was all about tight parts. interesting. Rigidity is everything… he just rips into Fysetk with bad linear rails, poor quailty printed parts, wires too short, top too low… wow. hot end isn’t high flow rate and it is a mess.

I see that all the time, and makes me shake my head. I like to mount stuff close as possible to where power is applied.

On the Primo, that’s the core rail brackets, so that’s where my drag chain mounts. The LR3, it’s on the line where the X belt goes through. Couldn’t mount there, but that’s where the vacuum hose is anchored.

For a 3D printer, you need wires. Maybe with a CANBUS board you can reduce it to power and a data pair, but you need those at least. If they are anchored to the print head near center though therw shouldn’t be a lot of torque on the print head.

I haven’t (and probably won’t) watch the video - but it could equally be called “how stupid is relying on one linear rail to balance your print head”, or “why not run you wiring loom correctly?”

EDIT - ahhh - skipping to 7:32 but still not watching I suspect my point is being made! ![]()

Correct me please if I am wrong - but a linear rail is called “linear” for a reason! In the example above, a cable run parallel with the rail could have solved the problem before it existed.

the problem was cheap linear rails with a lot of excess slop allowing the print head to wobble. The solution was a more expensive linear drive with preloaded bearings so it was a tighter fit and less wobble combined with an aluminum hot end holder to stiffen it up. The wires were perceived as bad, but not really outed as the problem, merely an accompanying possible issue so they switched to canbus. I didn’t get the sense that they really made much difference compared to the rail and the other pieces being swapped out.

Wow! Interesting, the problems they brought to light there are surprising! Nice Video!