It’s actually pretty simple to line up these “outriggers”. Note that this is very different than if you were to try to use two rails on the LR–that’s an entirely different issue, and much more difficult.

I’ll try to describe this in words, but if I’m not successful, maybe I can prepare a couple of drawings.

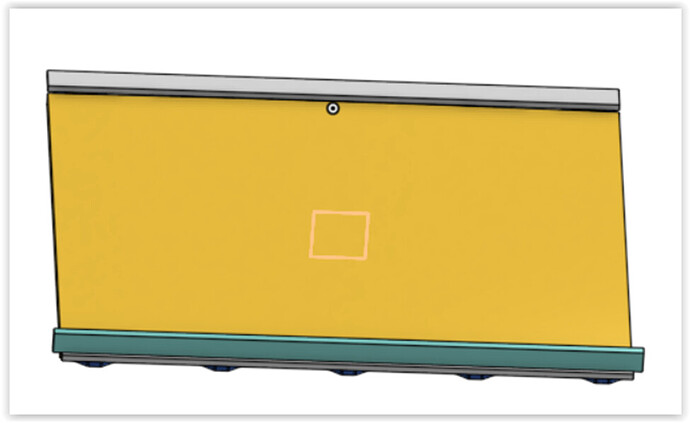

The first thing you need to do is to attach one of these outriggers to the EDGE (y-z face) of the table you plan to use and get it to be straight. You’ll want it’s (x-y) face to be approximately parallel to the TOP (x-y face) of your table but the exact alignment doesn’t matter. Once you have one end attached (but not extremely tight… it needs to be able to rotate a little bit in the y-z plane.) you can

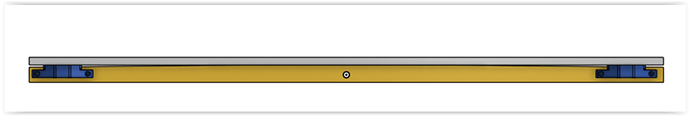

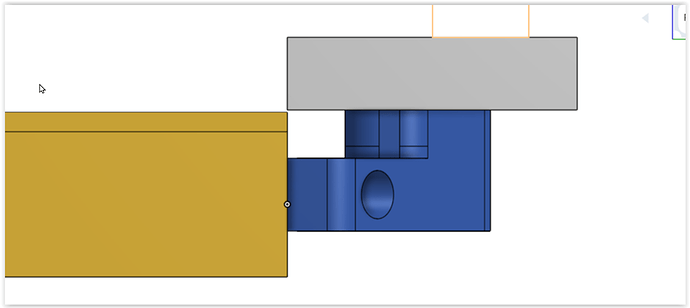

attach your level using clamps to this outrigger and carefully rotate in the y-z plane so that it’s at about the same angle as the table surface, and fasten the other end to the edge of the table. These fasteners should be very close to 90 degrees. The design that I showed is one such fastener, but the concept is pretty simple. However, I couldn’t find any inexpensive and rigid solutions which is why I 3D printed mine. You may want to add some more of these brackets while you have the level attached to prevent sagging. (I have 5 along the y-z edge of my 63" table.)

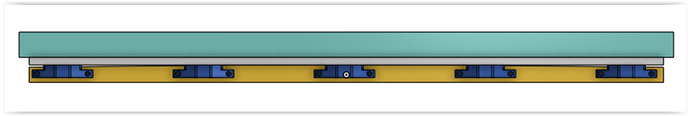

At this point, you will have one of your outriggers attached to the y-z edge of your table, with its x-y face more or less parallel to the table top, depending on how non-flat the table is. (Note that there is no reason that the two surfaces need to be coplanar, but you won’t want your outrigger to be too much higher than the table ţop. (The LR needs to be able to drop down low enough to flatten the table.)

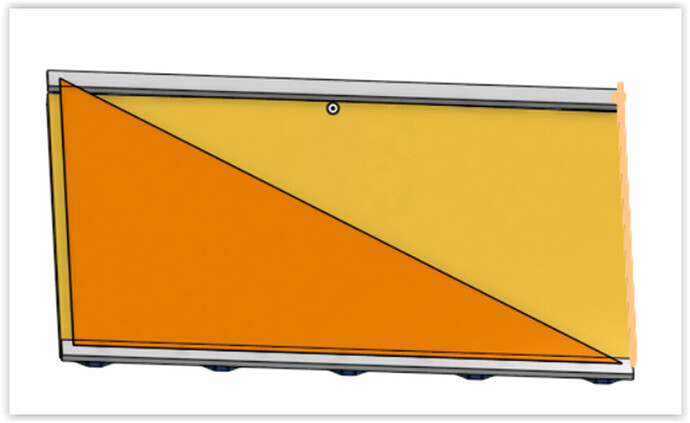

The rest of the process is pretty simple. You take the second ourigger and attach it to the opposite EDGE of the table. You will clamp a straightedge or second level to the face of that outrigger so it doesn’t sag.

Ideally, your right angle brackets will be adjustable in the z direction because you want to use your level ACROSS the outriggers at one end, and then the other end. Again, you don’t want the outrigger to overlap the face of your table top.

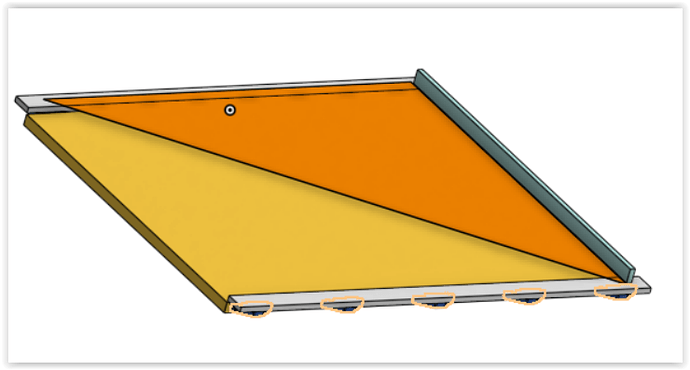

If you have followed this so far, you will wind up with the two outriggers with coplaner x-y faces, which is where you’ll mount the LR. They will also be fairly close to coplaner with your table, but being exact doesn’t matter since you can now use the LR to flatten the table. Also, the spacing between the two ouriggers is unimportant since the LR simply rides on one rail and the other side’s travel is determined by the gantry. It will run parallel to the fixed rail on the other outrigger.

One thing to note: this approach will make your table a few inches wider, which means the LR gantry will need to be longer in the X dimension. In my case, I actually trimmed about 1/2-3/4" off both faces because they weren’t perfectly flat and perpendicular to the table top and so that my LR would be able to ride on these outriggers.

And, just for some “eye candy”, the photograph shows the first flattening efforts of my table (aka “Guido”) which had a substantial crown, about 3/8 inch center to edge. Now, the area in the center is about 700mm x 900mm and is flat to less than +/- 0.5mm across them entire area. This surface is plywood, so if you look closely you can see the boundary of the top layers due to the flattening.

Unfortunately, in my case, the crown is so severe that at the +/- y extremes, the drop off is still ~8mm so I’ll probably glue some 1/8" Masonite across the ends and then flatten that to the same height as the center area. The spoil board will be on top of this, and should in the end be quite flat.