Hello, I just found this system and I’m very interested. However I’m having a little problem with choosing a kit I was wondering because the Primo kit is cheaper then the lowrider but the lowrider is more stable at larger sizes when looking at the instuctions. I’m looking for a machine with a workspace of 32"x26". I would be making signs, guitars, and flags which don’t require much precision as for as really fine details. I know the lowrider can go faster and is more accurate at faster speeds but when cutting really fine detail things with little movement such as inlays it will be ran a lot slower do to the hardness of the materials. I believe the Primo would work fine with standard conduit until I can upgrade, but i know the lowrider will handle it easily. I’m trying to keep it as budget, and as low profile/as mobile as possible so I’m asking everyone a lot more experienced with these systems to help me. I would really like to save the $100+ usd in the difference between the two if possible.

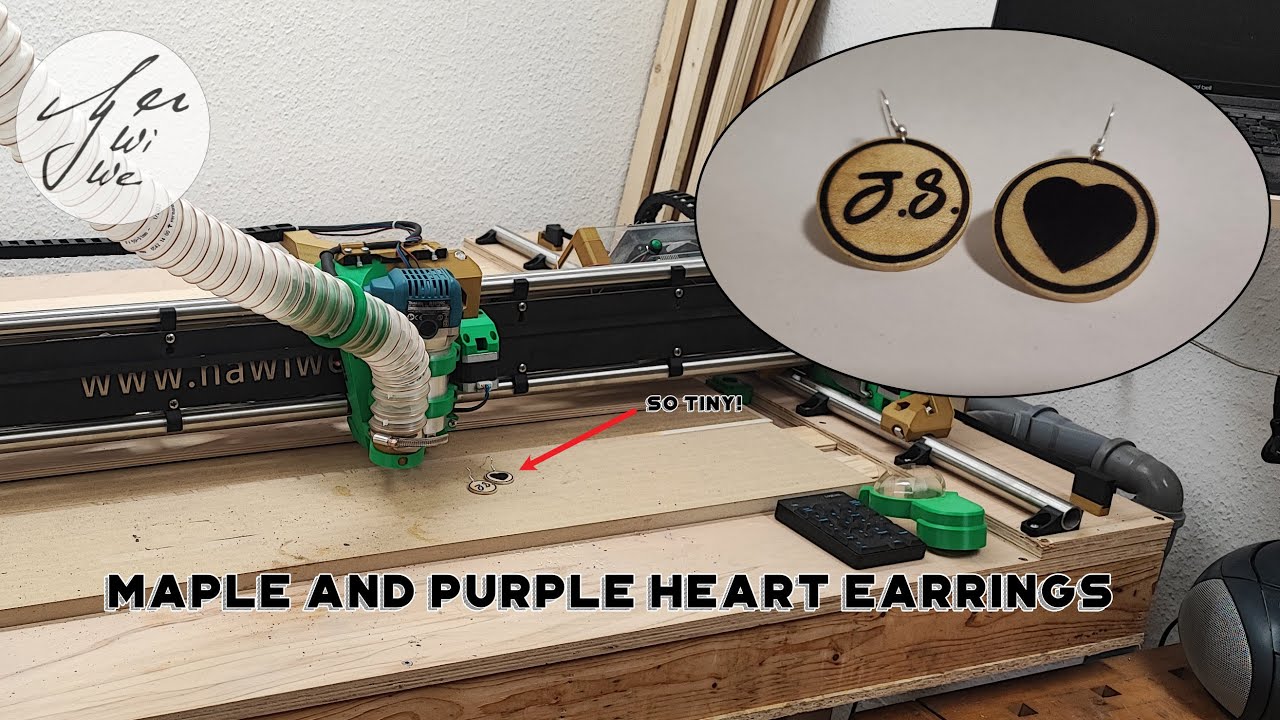

The LowRider can do small details just fine, I made tiny inlays with it:

Both machines are great, I have had the Primo for three years before switching to the LowRider and don’t regret it. I did manage to have some serious flex in my LowRider, but that’s because I always try to go faster, beyond the “official” capabilities of the machines.

Definitely the LowRider then, you are not going to be happy with a Primo that large. Mine was a little smaller and had substantial chatter in the middle, you really don’t want that. ![]()

I know money can sometimes be the issue, but it will not be the $100 later. You need endmills etc and buying cheap ones is always more trouble and more expensive in the long run, ruining wood and stuff. Do it right the first time and rather wait a month longer. ![]()

Welcome Austin!

At the size you are looking at, I would concur the Lowrider is strongly recommended.

While the MPCNC is great - I had a Burly (version prior to the Primo) running about a 21 x 32 work size. I got a ton of use out of it, but eventually built a Lowrider to work with harder materials and an even bigger workspace. I kept the MPCNC setup for a while and considered maintaining both, but found the LR3 to be overall better for the projects I was working on (which are similar to what you describe) and didn’t use the MPCNC enough to justify keeping it active.

My LR3 is more precise (possibly because my MPCNC was a crude first build and a bit tired by the end) and just as fast for all practical purposes. It is possible that an MPCNC can hit higher speeds unloaded, but once you start running a tool path, the feed rates are going to dictate the speeds to be essentially the same. In fact a stiff LR3 can push through material faster or with a deeper depth of cut.

I think the cost difference of the kits is actually less than $100 though you can easily hit $100+ differential with the most common routers (DeWalt DW660 / Makita RT0701C). But you’ll get a lot of that differential back once you add hearing protection appropriate for each ![]() (my DW660 is ridiculously loud).

(my DW660 is ridiculously loud).

Plus as Philipp points out by the time you get all-in that difference starts to become an increasingly small percentage of the machine cost anyway.

But, whatever you choose, get ready for a blast - it is an immensely satisfying hobby and a great community.

Hello, Thank you all for the advice, just a couple of questions, I know bits are expensive and why they are but have any of you guys tried the bits and endmills they sell on here? I mean $4-$10 usd for a bit is really cheap, I mean that is cheaper than amazon and normal bits are usually $40-$70, I was just wondering about the quality I know they aren’t as good as the more expensive bits, just wondering if anyone has tried them. Speaking of Amazon My other question is I know that buying the Jackpot or SKR Pro are probably the best, but do you think that a cheap controller from amazon that is half the cost of the jackpot would suffice as long as it has 5+ drivers? Right before I sent this I was reading the LR3 instructions and it says “The Z direction (height) is best kept to 80mm. This allows for 1.5” of cutting depth, that is a lot. If you need to cut more than 1.5” deep this is not the CNC for you” I’m going to need at least 2" of height, I know it might sacrifice some stability but would it be able to handle going up 2"+, pretty much is the machine capable of going that high. I’m mainly talking about cutting out guitar bodies and flags made out of 2x boards. That’s why I was looking at the Primo because i could have the size and height. I know that there is a maximum depth bits can go themselves. If you could let me know your thoughts that would be great.

Do you mean the ones in the V1 shop? Most of those are 1/8" shaft, which explains a lot of the cost difference compared to 1/4" or 1/2" shaft router bits.

I’ve had good luck with the V1 bits I’ve purchased, but I’m using them in a Dewalt 660 which is designed for these small shafts.

Dan and Doug made remixes for taller plates so you can get that extra length you need. Since it is really late I don’t have time to search for it, but it is here in the forum somewhere @DougJoseph, do you know where it is by chance?

Both Dan’s extra tall plates and my remix of the same are provided in the Printables listing for my remix of Peter H’s fenders.

I will get the link and come back to add it. Here it is:

https://www.printables.com/model/805777-lowrider-v3-cnc-fenders-for-various-stock-tall-yz

@Arayl96 if you do this…

In the Files section, at the bottom under “Other Files” the vectors are provided. You’ll need 50mm longer lead screws and 50mm longer linear guides.

Hey Guys, Thanks for the information and links, any thoughts on the control board question. I’m sure most of you guys have used both screen and non boards. I’m use to the screen from my 3d printers but but I also have a computer in my garage where this would go that runs my laser engraver that doesn’t have a screen. Any thoughts on a cheap $20-$30 control board with 5+ drivers from Amazon or so I really spend the extra on one of the V1 provided options?

The Jackpot from V1 is a great option, comes preflashed with the firmware and has Wi-Fi which lets you use any old smart phone / tablet as a touchscreen interface. Also allows option for adding a FluidDial pendant.

So in looking I would need to buy 4x 200mm linear rails and 2x 200mm T8 lead screws, or would it need to be 250mm

And I assume this could be added at a later date after the initial build has happened

I don’t think you are going to find a suitable control board for less than the jackpot anywhere.

The $20-30 ones I see are parallel port (LPT) ones which you could get to work with a great deal of effort, but unless you are trying to use a 15 year old computer it’ll probably cost all your savings to add a parallel port to it and you’ll have to run teathered.

An arduino mega / ramps is plausible but will only save a couple of dollars once you add drivers, will be harder to setup, is also tethered and will likely not prove to be durable.

The jackpot runs headless so you can control it from any device with Wi-Fi. It is easy to setup and has tremendous support from this forum. It is sold with extremely low markup and is roughly half the cost of comparable custom solutions.

The V1 store bits are a tremendous value. The are good quality, Ryan buys in bulk and passes on the savings to the point you can’t get them for less anywhere.

The standard size is likely more adequate than you think, but while you “could” swap out plates later if you expect to go there it would be much better (and cheaper) in the long run to start with the tall plates Doug pointed to.

Yes, this is correct. 200 each for both the lead screws and all the linear guides.

Yes, it can be switched later to tall plates. That would require dismantling the old plates and moving everything to the new plates.

I want to echo what Robert has said here. Ryan is exceedingly thoughtful and generous and sells things with considerably lower markup than a lot of places do.

Again, ditto what Robert said.

I agree that for the size you require, a Lowrider is an awesome machine. I had a MPCNC that was smaller that you’re requirement, and I saw enough chatter that I switched.

But I just wanted to strongly contribute that Ryan does a great job through the V1 Engineering Store of offering products with a great balance between cost and value. The Jackpot is a great example. For that price, it comes with a knowledgeable community for troubleshooting, support from the vendor, starter config files, and plenty of options with the FluidNC firmware. I’ve found the bits he sells to perform well in the materials I cut, although they may dull a little faster than much more expensive bits. I do run a few other bits for chamfering and whatnot, but I suspect I’ll continue to use the bits from V1E unless I need something specialized for a particular project. Extra endstops, wire, bearings, etc, I’ve found useful in other projects as well. Again, probably not the best money can buy, but a really good balance with value.

My experience, YMMV,

After doing a little pricing I think I might go the route of buying all the parts individually from the V1 store and then just buy the rails and rods separately so that way I’m not spending the $300 for the kit and then $90 for the longer rails and rods, I’ll be in about $280 for everything minus the cost of hardware if bought individually and I’ll put that $90 I’ll save into the jackpot, from what I seen you can buy everything in the kit on the shop individually minus the hardware, please correct me if I’m wrong

Do you possibly have a STL file for the tall plates? For some reason I’m having trouble converting them.

Are you trying to print them in PLA as opposed to cutting them? If so do you have a printer big enough to do that?