That tft isn’t the one we use. I don’t have precompiled firmware for it.

Well sorry ear that!

If I´m not wrong, to compile a firmware you need the actual TFT?

Regarding this?

Well another improvement, I did a series cable for the motors!! WORKS

I´m looking to contact people who use my TFT or my SKR

Best and thanks

Does that screen have Marlin mode (and two gray cables?). You could probably get along fine with that.

Hi!

2 grey cables and one black. i connect it to the mother board and try to use the motors manually, no results.

i think it has merlin mode

If you hold down the knob, it should ask to go into Marlin mode. Then only the knob will work, not the touch screen. If you can use that, then you are all set.

Hi!!

Yes i can control with the Marlin in the TFT.

I guess now i need to set it up all together in the table and try to move all the parts?

I still Dont know how can i change the icons in the TFT for some that are more accord with a CNC.

Thanks I will keep you inform!!

Editing the touchscreen is surprisingly tricky. You definitely need to be able to compile it with platformio. With it tft files, there is source code and you can set the screen type in the platformio.ini file. Then flash it.

W.r.t. the rest of your build, just keep following the instructions. It should be fine. Let us know how it goes so I can recommend that turbo build to others or not.

Well thanks !! i will try to finish the hardware and then get back to the firmware.

Which program will you recommend to prepare CNC files?

When i was using CNC i work with Autocad 2011 so this i 10 years ago!!

I will keep you inform!!

Take a look at the software workflow for some suggestions.

But estlcam is an order of magnitude easier.

Also try the test crown premade gcode to check out the machine. Then look at milling basics and estlcam basics.

Thanks

I´m back on track!! i was busy with my daughter!! She had a week of at the kindergarten!!

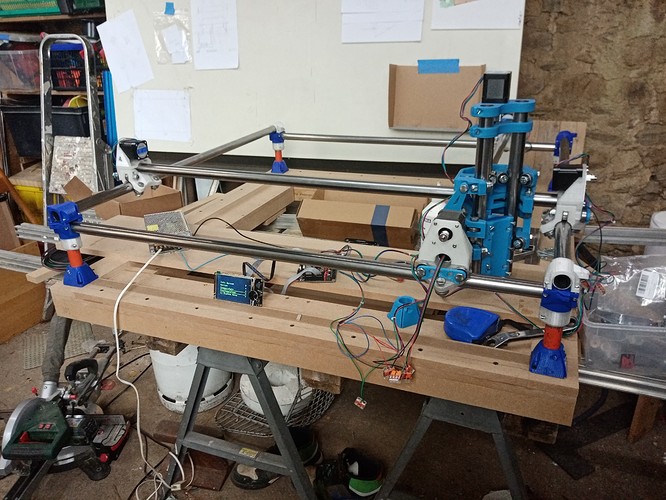

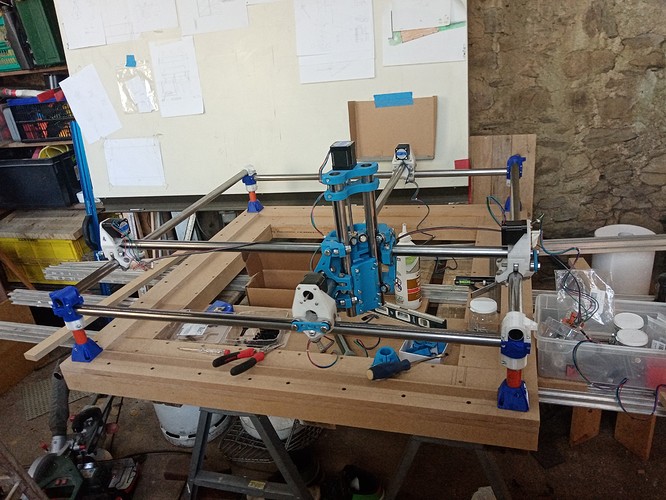

So I got the base, the cables set up and i tested the motors, they work and move, I need to prepare the final set up of the components!

I´m having a lot of fun and when i see the motors moving correctly we nice!!

thanks

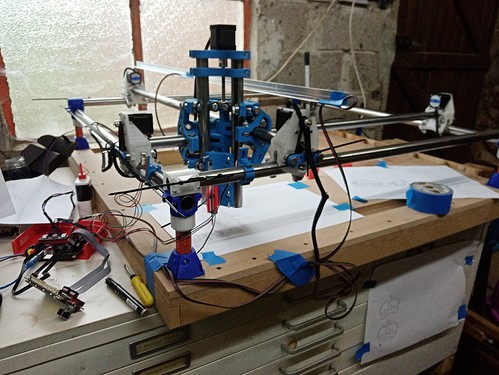

HI Guys, GREAT NEWs!! I did it!!! is working.

I clear a spot on my workshop and install a PC next to it, with the pen works fantastic!!

I’m learning a bit of fusion 360 to be able to produce some milling noise!!

The first im using is “Estlcam” to get use to the workflow.

Thanks a lot for all the help!!

Woo Hoo!

You are still not a beginner. You are now and experienced CNC builder!

Well done!

Congratulations.

Now you can show off your successful cuts.

BR

Paolo

Hi guys!! i have another Question !! Is regarding my Anet A8.

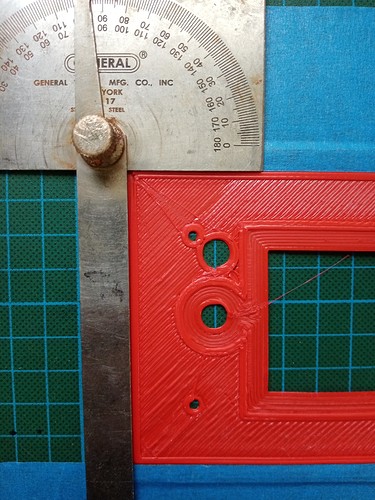

I’m printing the box for the motherboard and controls of the CNC, the box is not to big but ani time i print is offset to the back.

Did you had this problem?

Thanks

Can you tell me what project (box) you are trying to do so I can check?

BR

Paolo

Hi

is any project, when I go big like a box 120mm by 90mm and 25mm highs.

the front of the box and the back of the box has a displacement.

So: more or less is 1,5 degree but is not square, i check the tension on the belts and all the stability od the printer.

Thanks

OOPS I understand.

It looks like x and Y axes of your printer are not perpendicular.

Unfortunately I don’t know the Anet A8 printer so I can’t make a suggestion for you.

I hope someone else will help you.

BR

Paolo