We’ve seen folks deform stainless tube with the mpcnc. Aluminum won’t stand a chance. You can try it though.

I come from a world of gantry mounted part removal ‘robots’ many utilizing steel reinforced timing belts that have millions of cycles without issue and are still accurate to .1mm repeatedly. So I agree with you, the belts you are using have never been an issue for me. If I need to hold tighter tolerances than that then I’m going to use a different more expensive machine.

Whereabouts is “here”? I’m in Edmonton.

Well, given that I work for a company that sells steel tube, (though not in sales, so I’m not supposed to give pricing) I get a pretty good deal on tube, but not sheet. I did take a quick peek at sales history, and saw some 3X3X.125 sold as a “cash sale” for about $8.05 CAD per foot. That means someone who doesn’t have an account called up and asked for some 20’ lengths (Might have been 40’) and paid for then with a credit card.

I’ll grant that aluminum is probably more suitable to a plasma machine, as it doesn’t have to face cutting resistance. Same thing for a laser. In both cases, reducing weight is probably more of an issue than durability. It’s using a spindle or a router that the durability starts to come into play. Even so, I’d probably rather use something like a POM wheel on aluminum than a skate bearing.

Even here in Canada, we are nominally a metric country, but so many of our building and construction materials are more commonly available in imperial measure, because we have so much cross trade with the USA. Even in the grocery stores the receipt might show you that you paid $2.18/kg, but the sign will say $0.99/lb. Buying hardware like screws or bolts in the big box stores, they’ll all be inperial measure, too. I have to go to a specialty bolt store to be able to get metric sizes, and they often cost much more (Though there are a FEW specialty stores where the prices are comparable.)

And now, just to throw a monkey wrench into the works… The shelf labels at Home Despot are all in imperial measure, but not all of the materials are. I recently went to replenish my supply of 1/2" plywood, and when I tried to fit it, it was a sloppy fit, because the material was actually 12mm. I had to re-make pieces. Similarly, I have some 3/4" material that is actually 18mm… But I also have some that’s 19.05mm (and 12.7mm for 1/2") so now I need to check the material that I’m buying for what the actual dimensions are.

I am all for belts as plasma is all about speed and high acceleration! I have very issues with mine. And I agreed with u on the accuracy thing. I however had a baffling problem when I first built my first lowrider with steel reinforced belts, where my machine seems to “loose steps” but constantly… turned out I had broken steel strands in the belts over time in the areas most used… it was tough to diagnose… that was with 16 or 20t pulleys can’t remember… I now use like 44t on my plasma or somthing

Where abouts in canada are you located if u don’t mind me asking?

Engineering in the US is mostly metric. Non engineering (the other 95%) is imperial units. Car parts and bolts on import goods are usually metric screws. AFAIK, machine shops have a bunch of tooling that is 50 years old and the new stuff they buy matches the old, so it is all imperial.

I have a kid in second grade and they just had a session on units and they were teaching inches, feet, oz, cups, etc. It is still very much more popular than metric here (in the US, Colorado).

The company I work for has offices in Edmonton, Calgary, Cambridge and Whitby.

Thanks for the insights, and sorry for going off topic:)

If we haven’t gone off topic in 60+ posts, then we aren’t having enough fun.

So, probably old news for you guys, but I was browsing Thingiverse and found this clever solution.

Apparently, the idea came from this CNC alternative. It’s roughly the same way of working as is with the lowrider.

Maybe the Y rail could be a good idea to incorporate in LR3. It’s a cheap linear rail anyone could source local, in the length needed? I believe it could be a way to keep the rest of the parts similar (but with some updates : )

Belts stretch. It gets worse the longer they get, and there’s pretty much no way around it.

You can get wider belts but the width only goes so far. You can’t get GT2 belts that are 50mm wide, and even if you could, it’s probably not viable for other reasons.

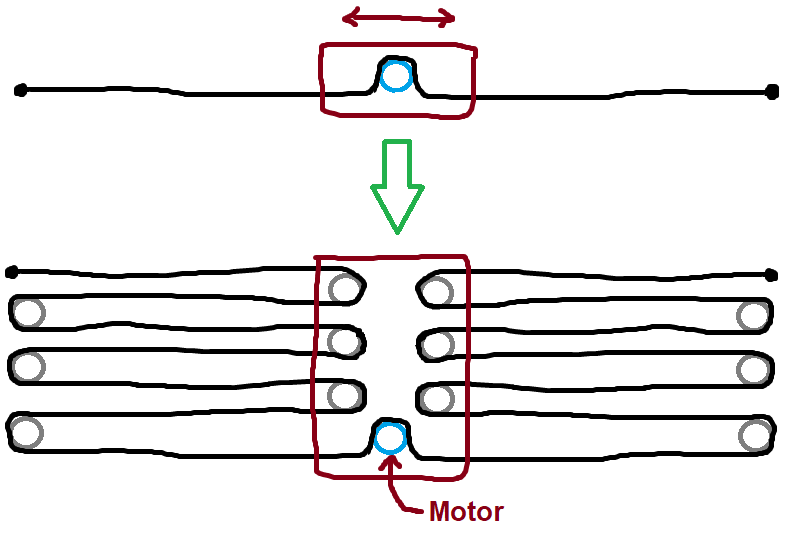

But belts can be very long, so how about a block-and-tackle to add stiffness?

This allows the belt stiffness to be arbitrarily high if you are willing to add enough pulleys and extra belt length.

This also effectively gears down the motion, so you might want a larger pulley on the motor to get back some speed. And if you have a large drive pulley, you could change all the pulleys for large ones, and then perhaps you can use the white belts with steel cords, although I don’t know if those are in fact any stiffer than regular belts.

To me this is out there, and hilarious, and yet at the same time it should actually work and it is still better than ball screws. So maybe not your every day baseline design but a stiffness upgrade option.

They do make double 10mm pulleys…

Oh but that’s much less ridiculous.

It’s my backup plan.

Just put a spring loaded belt tensioner on it like a car’s serpentine belt has.

I don’t even know why I laughed out loud at this

That adds flex to the system.

I have to agree. The industrial robots we have use belts and maintain the same accuracy as you’re seeing. I’m happy with the belt performance on my mpcnc, but seriously thinking about adding a lr to the other toys in the garage.

You shoud, one complete the other…

Another thought about belts vs ball screws. In 24/7 industrial use in our plant over the last 3 years, we’ve had at least 6+ ball screw failures to zero belt failures under normal conditions. Not including machine crashes from operator error, which is not a normal condition…