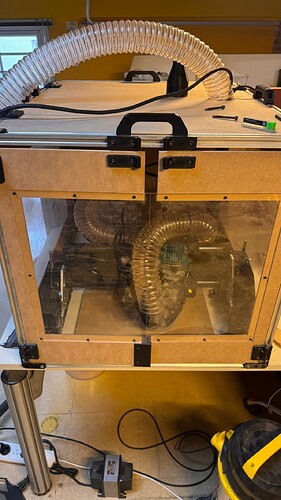

I just finished the build of this small form factor LR4. It looks pretty cool in person in all black. I’ll definitely build a black table for it (I need to build a drop table since I need it to machine 70mm high pieces), which will make it look really nice. Anodizing is probably a bit over the top :). Enclosure helps keep all the dust in since it shares a space with my electronics bench and other stuff.

A few notes from the build whilt it’s still fresh:

- the dust shoe is a work of art. Truly wonderful how simple it is yet how stiff and reliable it seems. Crazy design

- the overall build seems MUCH stiffer than my LR3. Granted, it’s a much smaller form factor, but still. I guess I’ll compare apples to apples when I update my full sheet LR3 to LR4

- I fumbled my build a bit and mixed the location of my Z stubs, so I needed to detach de gantry and reattach. I found this to be a bit cumbersome: the cables being already wired made it a bit tricky. For my next build, I think I’m putting some connectors at each of the ends of the gantry for ease of assembly/disassembly

- On this matter, I also got a bit tangled up with the X belt when disassemblying the gantry, though I can’t recall why. All I remember was thinking that maybe both ends could be attached to braces? Although maybe that would be suboptimal for maximizing X travel

All in all, I’m super happy with the machine. It’s replacing an old traditional DIY cnc that I had, so I can’t wait to put it to work and compare.