The reason for why I ended up in this mad house is that I last spring got a sick leave from work. Things had been very rough for a long period, and at one point my doctor gave me a sick leave for quite a while. (I appreciate our scandinavian welfare system!)

During this period I had to come up with some kind of project, not to sit on my behind and sulk.

I came up with the insane idea of making a water wheel in a small creek river next to our house, to generate electricity, to charge my bike. I tried to make one in waterproofed construction wood (for decks and such), but it was way too huge and clunky and impractical for the little creek.

I then asked a friend of mine who is a engineer in “waterpipes(?)”: How can I make a smaller type of wheel in a way that is techincally precise enough not to wobble and fall apart right away?

He said: you have to find some sheets of plastic and CNC them. I asked him: What is a CNC? And that was when I fell down the rabbit hole. I quickly came across MPCNC, and then I had to figure out: “How does a 3d printer work?” And the rest is history.

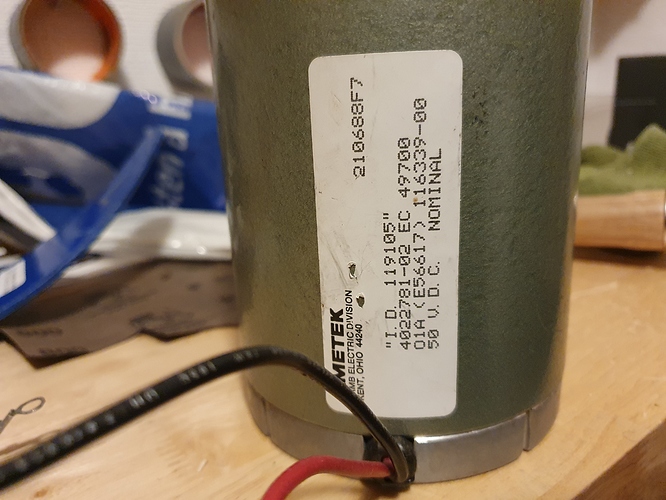

WELL - back to the water whell. I still don’t have much clue about electronics… how can I make such an apparatus, on the electronics side? My plan is to get a dynamo from a car, that has a built in 12v regulator. Is it as simple as connecting the 12v generator to a 12dc to 220 ac converter?? Is that it??