hi does anyone knows the spec for cutting

19mm birtch plywood

That will all depend on your particular machine, its size, build quality, bit selection. All kinds of things. I can tell you what works for me in birch plywood and it might not work at all for you. Or you might be able to go twice as fast or twice as deep as I can. Best way to know for sure its test cuts. See what works and what doesn’t and go from there.

If you want to give us some specs on your build, and maybe a few pics then that can help a lot. If you have a build thread here and I am just not remembering then I apologize. Link it and we will take a look and help you as much as we can!

hi

i have a lowrider cnc v3 whit skr pro v 1.2 board

my cutting size is 122 x 244 cm an a router dewalt 611

So a full sheet LR3. Ok that’s a good starting point! I am not sure what size bit you are planning to run so I’ll assume 1/8" or 3mm. From what I remember on my full sheet LR3 for birch plywood I would run between 15-20 mm/s feed rate and 4mm DOC. Like I said before your milage may vary but hopefully that will give you a good starting point. Make sure you have a good sharp bit. Preferably single flute and set your router on about 2 setting. As long as you are getting good chips and not seeing any skipped steps you should be good to go. If its all running smoothly you can try bumping up the feed rate or deeper DOC. But remember as you push harder you will induce more flex so probably a good idea to run a full depth finishing pass as well.

ok iwas thinking of using a 1/4 two flute bit but is good to know

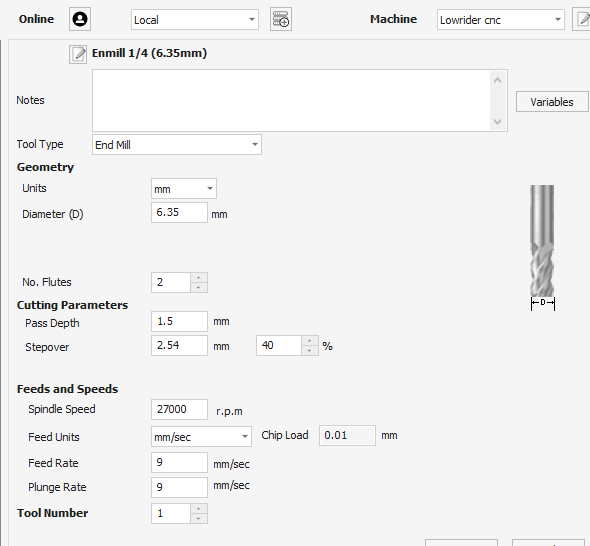

and i was cuttingat 12mm /s but it was cutting like 0.3 mm off so i droppe it down to 9mm /s

but it a but slow and router speed at 6

s from the info you are giving me i was way off

When you go to 2 flute you have to either cut the router speed in half or double your feed rate to keep the same chip load. Without the chips there is nothing to remove heat from the bit. So you end up heating the bit up and that dulls it. I run about the same settings with a 1/4" single flute bit on my old LR3. You should be able to do closer to 6mm DOC with the 1/4" Again… YMMV

I am using a 6mm 2-flute, so what you use and I am cutting 6mm deep at 3000mm/min (50mm/sec) and a router speed of 20 000k RPM. That is with a well-tuned LR4 though! For the LR3 my maximum depth was around 3mm with 2000mm/min, as far as I remember. This is also rather on the higher side. But as Jonathan said: start slowly and work your way up. ![]()

Nice! Was that for plywood? Got video? v1engineering-mods/lowrider3 at main · aaronse/v1engineering-mods · GitHub

The best way to approach this issue (IMO) is to start with the recommended chipload (CL) for your bit and your material. Then calculate the feedrate (FR) and router speed (RPM) from there.

If the end mill vendor/manufacturer didn’t supply a recommended CL (some do, most don’t), there are lots of charts on the Internet that can give you “typical” values. Most are in Inches/tooth (IPT), so you may need to convert to mm/min (IPT * 25.4 = mm/tooth) to get metric FR.

CL = FR/(RPM * # of flutes)

FR = CL * RPM * # of flutes

RPM = FR/(CL * # of flutes)

Here’s an example:

Chart from Chip Load: Guide for Beginners - MellowPine

| Material | 1/8″ tool | 1/4″ tool | 3/8″ tool | 1/2″ tool |

|---|---|---|---|---|

| Hardwood | .003”–.005” | .009”–.011” | .015”–.018” | .019”–.021” |

| Softwood/ | ||||

| Plywood | .004”–.006” | .011”–.013” | .017”–.020” | .021”–.023” |

| MDF/Particle | ||||

| board | .004”–.007” | .013”–.016” | .020”–.023” | .025”–.027” |

| Hard plastic | .002”–.004” | .006”–.009” | .008”–.010” | .010”–.012” |

| Soft plastic | .003”–.006” | .007”–.010” | .010”–.012” | .012”–.016” |

| Acrylic | .003”–.005” | .008”–.010” | .010”–.012” | .012”–.015” |

| High-pressure | ||||

| laminate | .003”–.005” | .009”–.012” | .015”–.018” | .023”–.025” |

| Aluminum | .003”–.004” | .005”–.007” | .006”–.008” | .008”–.010” |

Note that these recommendations are for Depth of Cut (DOC) = tool diameter. If DOC + 2x dia., reduce by 25%, and if DOC = 3 * dia., then reduce by 50%

If you wanted to use your 1/4" 2 Flute bit at the slowest RPM for your router (10,000 RPM) at 6mm DOC (1x dia), and assuming you select the middle of the Plywood CL range (0.012 IPT), then the formula for FR would be:

FR = CL * RPM * # of flutes

= 0.012 * 10,000 * 2

= 240 IPM (*25.4)

= 6096 mm/min (101.6 mm/s)

That is probably too fast for the LR3 (or LR4) to achieve without skipping steps, Although theoretically if you increased DOC to 18mm, then the value decreases by 50%, so you would be in the 3000 mm/min range that @Tokoloshe mentioned (Edit - as @Tokoloshe mentions below, 18mm DOC may not be physically practical).

If instead you use a 1/8" single flute bit at mid RPM (20000) the formula for 1x dia. works out to

FR = CL * RPM * # of flutes

= 0.005 * 20000 * 1

= 100 IPM (*25.4)

= 2540 mm/min (42 mm/s)

Hope this helps!

That is some fast machine!!!

3500 mm/s = 210,000 mm/min

![]()

Tsk. You are all confusing me with your mm/s because I have always done it with mm/min…

I’d say that this is impossible. 18mm is waaaay too much. I also like to use the Sorotec App for a rough estimate.

I just want to throw out there that plywood can be a bit of a wildcard. Depending on quality and glue, the same type/size of plywood may need different settings.

I treat it the same as hardwood in calculations. ![]() Except Poplar plywood.

Except Poplar plywood.