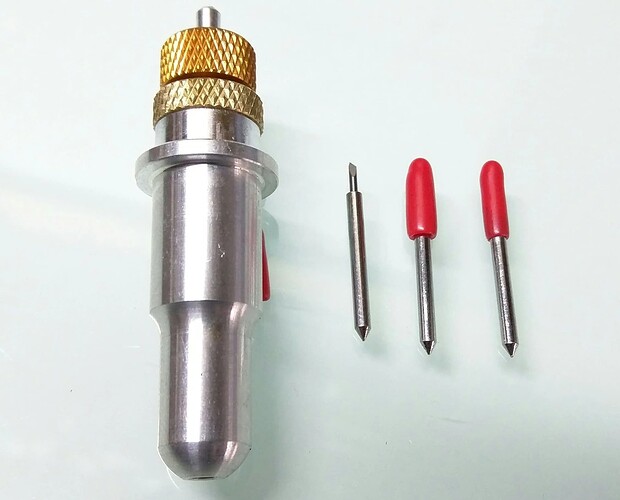

I am building a drag knife, how hard can that be? I have a prototype made and am ready to test, but I don’t know how to put it into the tool list and can’t find any info on doing that.

I made the drag knife with an adjustable offset as I don’t know what is needed yet.

I have also made a test file of a gasket to try cutting out of thin card.

Can anyone give me a few clues on setting it up please.

Is your drag knife one that has a tangential drive motor, or is it primarily a “castering” point that has a very small distance between the point and the pivot?

If the latter, you can simply enter it as a fine point mill or a scribing point, and use the engrave function with a very small depth of cut.

One like this in the shop: Drag Knife / Vinyl Cutter – V1 Engineering Inc

Note that in the picture the tip of the blade is offset from the axis of the blade:

It is also has a spring to “cushion” the tip of the blade. I set mine to have Z-Axis be zero at the tip of the holder right at the surface of the cut and just extend the blade just enough to cut the material.

I hope that helps some.

Mike

Thanks for your comment Mike.

No Mike, I have that type of drag knife on my vinyl cutter, the type I have designed is based on a commercial brand type as shown below.

It has a razor blade and can be adjusted for the offset which can be between 0-3 mm

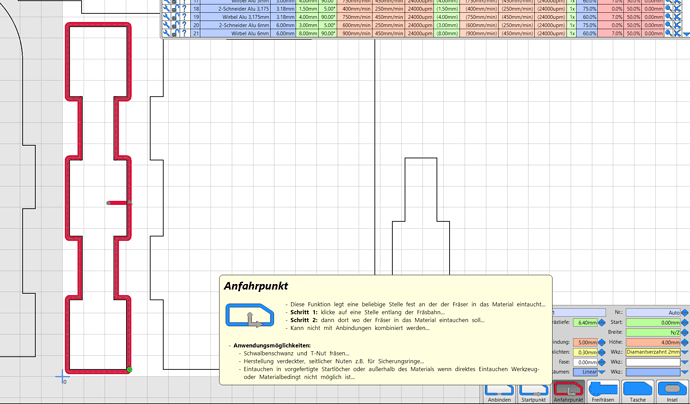

After having loaded the CNC program, in the window where you have the touch plate function, home etc. there is a drag knife button where you can input the offset and it calculates it on the fly.

I did an air cut on the screen to see what would happen.

I must be doing something very wrong as it doesn’t work out properly.

What I did in CAM, I loaded a gasket file and used an engraving tool set at a depth of 0.6 mm

I saved that out as a CNC file and loaded it into Estlcam.

I selected the drag knife icon and the window came up asking for the offset value, which I tried first 3mm which is pretty close to what I have the knife set at.

The resulting file produced has some bad cutouts in strange places.

I tried with several offset values and they all have this issue, some worse than others.

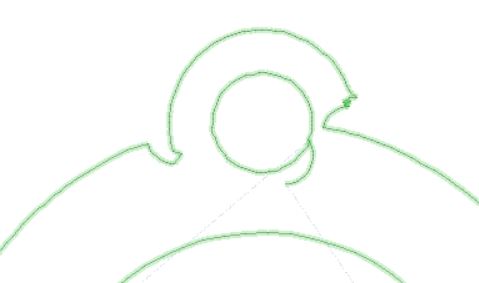

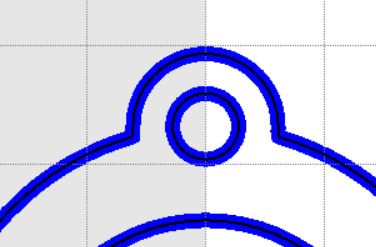

Here are some screen captures.

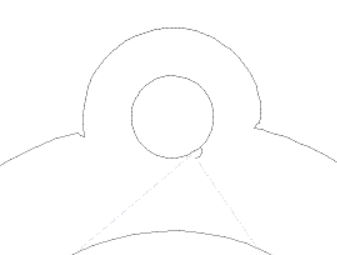

1mm offset.

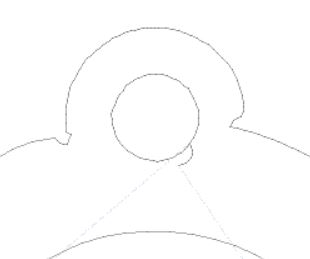

2mm offset

3mm offset

4mm offset and cut. The green parts are all at 0.6mm deep, so the gasket was a fail.

Maybe I have to draw in some lead ins or something? so that the knife starts outside of the wanted part?

The CAM file doesn’t have any artefacts at all.

The more offset you put in, the more garbled the toolpath looks, because it calculates the turn radius. If it went directly up or right the corners would be filleted, so it goes a little further in and does a semi-circle to turn the blade before it cuts again. It only makes sense once you cut something, the toolpaths look horrible. ![]()

Have you tried a cut with the tool path set at the correct offset on some scrap paper to see what happens? It may be those artifacts are just what’s necessary to position the offset tip in the correct place to get the actual profile.

Okay, next step is to try for real. I will setup my first drag knife cut and hope for the best.

I just did a test cut, a complete failure.

The artefacts are more pronounced in the actual cut, the cutting direction on some of the cuts was not in the correct direction, so maybe that has to be set in the file?

The cutter worked fine where it did cut, but the holes that were to be bolt holes in the gasket are completely and utterly not right.

The big hole in the centre of the gasket has a lead-in that is in the gasket area, so that was a fail as well. It would be nice if I could control the lead-in start position in a part of the waste area.

Maybe that is what is needed, but I can’t find any documentation on that.

Looking at the actual cut, the outside of the gasket that had a lot of strange cut outs, actually came out pretty good, it is the inner holes that are the problem.

You can set a lead in in the normal cam portion. See the little line inside the part (just used the first project as an example), you have to click the button I highlighted. Then you can put the start inside the circle.

With those small dragknifes Ryan sells it works quite well, so there must be a catch somewhere.

Okay I will explore that and see if I can work it out. I thought that there must be a way to control the lead-in somehow.

Thanks for the tip Philipp.

I have a couple of those and plenty of new blades in several angles. I used to have a sign business before I retired and I still have a couple of vinyl sign cutters. Those sign cutters are great for vinyl but not much good for cutting gasket material or cardboard boxes etc, so that is why I wanted to use the mill that has a flat bed.