I was going to wait until the year after next or perhaps the year after that, and show everyone my stunning new enclosed machine, but it occurred to me that the most difficult decision that I’ve had to make (twice) is about what size I was going to build my LowRiders.

I am definitely of the school of thought that “bigger is better” and was attracted to the Lowrider (2) initially because I thought the almost full sheet size table would make fitting out my van a doddle. The truth of that is that I have other tools, and enough experience using them that it didn’t get used at all in that project.

Then the LR3 came along, and I INCREASED the footprint, with another couple of projects in mind, and again armed with other more efficient ways of furniture building (for me) it didn’t strike a blow in anger. I can’t recall anything I’ve used it for that couldn’t have been done on one of those little desktop machines. (My Neje diode laser shares the exact same problem.)

There’s an expression in the photography world that the best camera you have is the one you have with you when you, and in my workshop for the rest of my machines it’s a matter of rolling them into position, clicking on the magnetic dust collector fitting and pressing ‘go’.

Given all of that - I think that 2026 will be the year of the downsize, and in doing so a lot of overthinking and off-(yellow brick)road adventuring is likely to occur, but here’s the plan -

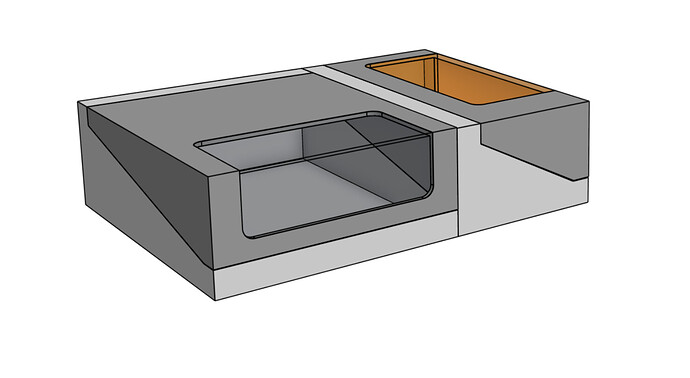

Within my existing table footprint, I can get both machines fully enclosed, and a usable CNC cutting area of around 600 x 850mm (about 2’x not quite 3’) - if indeed a larger project comes along It won’t be a huge project to build a temporary table for it.

So this is where I am heading - If I can nut out dust collection - I’ll worry about electronics after that! All comments and suggestions will be gratefully received, and I will start a separate construction thread when I get to that - but for the meantime - should I go smaller still?