Hi everyone! ![]()

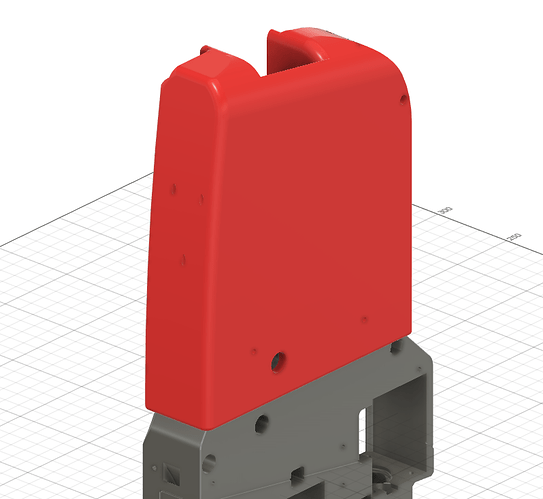

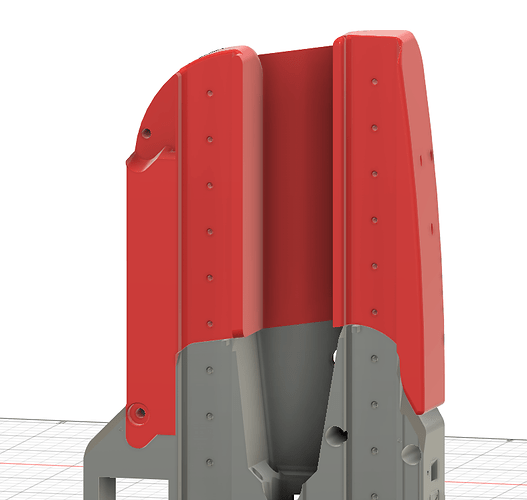

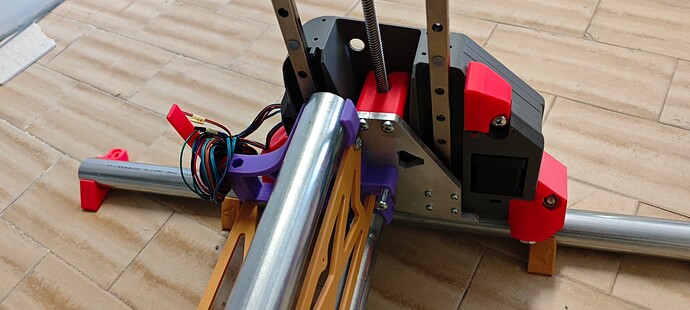

I’ve been working on a Z-axis extension for the LowRider 4 CNC, mainly to increase the vertical travel for working with tall foam and polystyrene blocks.

By replacing the original 150 mm linear rails with 300 mm rails (11.8"),

I was able to get around 250 mm (9.8") of Z travel, which is great for my use case (soft material + long tools up to 200 mm / ~8").

![]() I know the LowRider works best when it stays low – rigidity matters!

I know the LowRider works best when it stays low – rigidity matters!

But for foam work, it’s not a big issue, and this gave me the flexibility I needed.

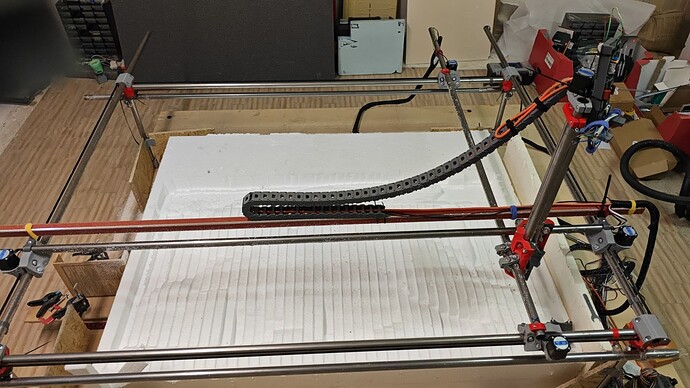

To make the most of this added height, I also working on a drop table with adjustable height: I can lower the work surface depending on the thickness of the material, keeping the gantry rails at the same level and improving tool access without sacrificing too much Z rigidity.

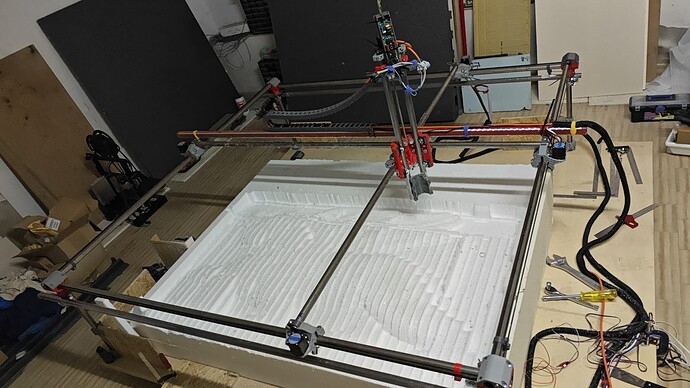

![]() I built my LowRider V4 with an X working width of 1500 mm (~59") and a Y length of 3700 mm (~145").

I built my LowRider V4 with an X working width of 1500 mm (~59") and a Y length of 3700 mm (~145").

The machine is assembled and ready, but I still need to finish building the custom table — it will include the adjustable drop-surface mentioned above.

![]() Backstory:

Backstory:

I previously tried building an oversized MPCNC Primo (1500 x 1500 mm / 59" x 59") with a Z height of 400 mm (15.7"). It looked amazing, but after a short time, the X-axis began skipping steps and started moving asymmetrically and in jerks. The build was just too large and flexible for my needs.

VIDEO LINK: first time hot rigid wire cutting Video

VIDEO: hot rigid wire first cut

VIDEO: First parallel milling cut with 200mm bit tool and 55mm 600W router

So now I’m testing the LowRider V4, which seems more suited for bigger format CNC work.

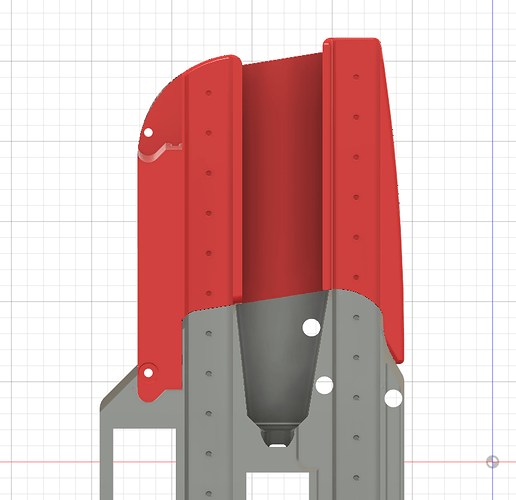

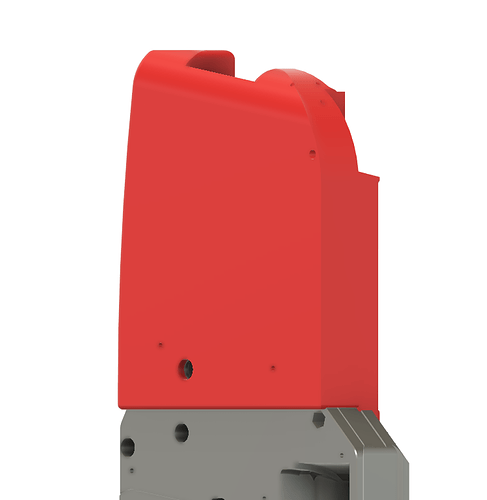

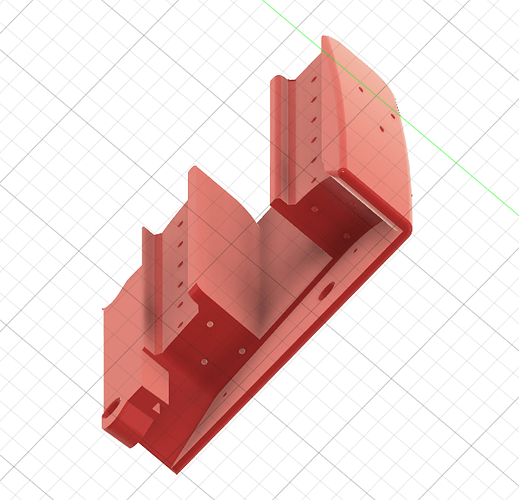

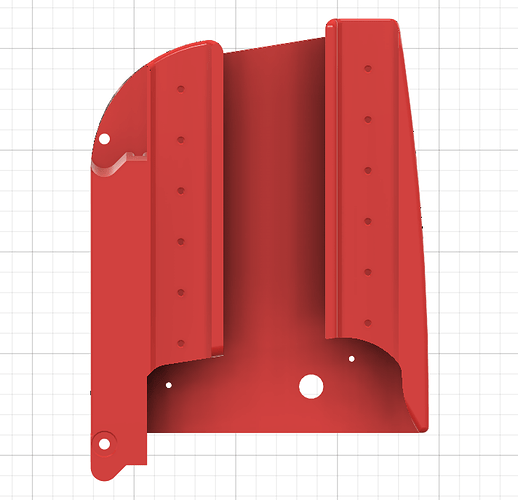

![]() I only had the original YZ_Plate_Min_V1.stl https://www.printables.com/model/1034840-lowrider-4-cnc/files STL file available, and had to work around some limitations in Fusion 360 ( negative XYSTEP files wouldn’t import cleanly). So I did my best but I’m actively looking for help to improve, optimize, simplify or even rethink it entirely if needed.

I only had the original YZ_Plate_Min_V1.stl https://www.printables.com/model/1034840-lowrider-4-cnc/files STL file available, and had to work around some limitations in Fusion 360 ( negative XYSTEP files wouldn’t import cleanly). So I did my best but I’m actively looking for help to improve, optimize, simplify or even rethink it entirely if needed.

![]() Suggested print details:

Suggested print details:

– Requires minimum print bed of 210 mm

– minimum supports needed

– PLA or PLA+ recommended

– Layer height: 0.2 mm

– Infill: 15–20% sufficient

![]() Printables link: printables file

Printables link: printables file

![]() Call to action:

Call to action:

If you’re interested in this kind of mod, or just curious, I’d love to hear your thoughts.

If you want to help improve the design, adapt it for other sizes, clean up the geometry, or even just discuss possible implications I’d be super happy to collaborate.

Thanks V1Engineering and V1 community for being an inspiring place to build and share!

Greetings from Italy

Mirko