Hi some advice would be welcome!

I’m cutting 3 cm thick oak with a single flute 1/8 mill with length of 32 mm. DOC is 3.175, feedrate 15 mm/s and spindle speed is lowest setting makita (10.000rpm).

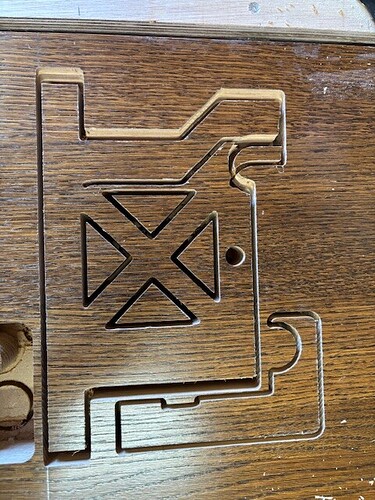

During the last outer cut the cnc got misaligned unfortunately. See pictures below. I tried to clean it up afterwards and the wood chips were really stuck in the cutting groove. Could this be a cause?

Should I de/increase the feed rate, or increase the spindle speed? Chips seem a bit large, but my experience is limited.

Near the end I set the makita to 2, and soon after it got misaligned by a lot and so it was milling with a DOC of about 25 mm. Not sure if this was because I increased the rpm or that it was just already misaligned by to much, or had to much stuck in the grooves.

I also made one earlier with a feedrate of 12 mm/s without any problem.