Hello, this is probably the 4th time I try to print the Z pole M file on different orientations with and without supports and the result is a plate full of spaghetti ![]()

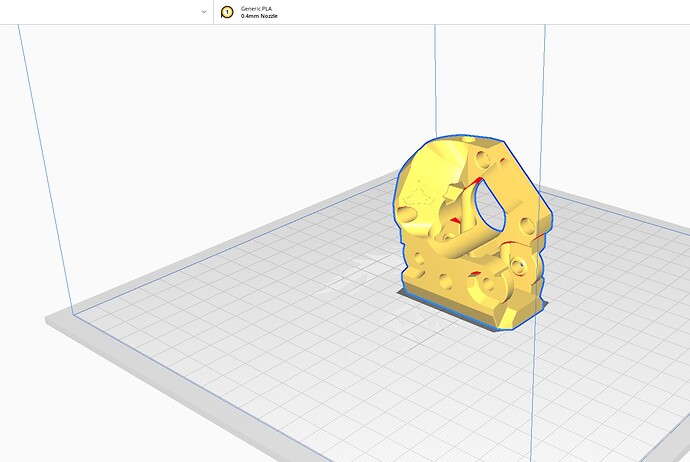

this is my orientation, Creality ABS at 260C /110C with 0.28mm layer height.

Apparently, it prints fine until about 15mm then layer shift happens and it’s a mess.

I did print other parts like the steppers holders without issues.

help is appreciated ![]()

All the parts are designed to be printed without supports in the orientation the file opens with. So if that isn’t working for you let’s see what we can do to fix that as changing orientation and supports is only going to add problems.

Layer shifts are a mechanical issue with your printer but I would say 2 things - ABS isn’t as good in this application as PLA and is harder to print. And .28 layer height is quite coarse when you have so many arches/curves/holes so I’s suggest .2 or lower.

From the documentation:

Recommended Print Settings: PLA for dimensional accuracy (PETG is also acceptable, if your dimensions are verified good and you are willing to sacrifice some rigidity). Two or more perimeters for through hole strength. There are some steep walls so no more than 75% layer height to nozzle diameter. No support should be needed for any part I have designed.

Thank you, these bigger parts are the only ones having issues, yesterday I asked on printables and I was told that this part should be printed on its side so I don’t think it’s being loaded with the correct orientation.

And just to confirm, you’re talking about the 3D printer right? not lowrider or primo.

Anyway I will try with PLA and see how it goes ![]()

Cheers.

I’m pretty sure I printed it in the orientation you show in the pic and it printed fine in PLA+. Layer shifts are a problem with your 3D printer. And I agree abs is not the best choice here

Assuming you’ve got an enclosure for your printer and you’ve printed projects in ABS before, try slowing down your overall speeds. Sometimes there is an awkward move in the gcode that your printer just doesn’t like and will cause a skip. This usually means your running speeds at just over the limit of what the printer is capable of in its current state.

And yeah like everyone else mentioned, ABS is unsupported and is a use at your own risk situation. I don’t think it’s necessarily a terrible idea to use it, but parts are designed with the rigidity and unsupported bridging qualities of PLA in mind.

The Z Post orientation looks good. I used brim…

I think latest v4.1+ models are oriented for printing now. With v4.0 I printed wrong orientation for some parts, for example…

Printed PETG 0.6mm nozzle, 0.32mm layer height, 3 walls, recommended infill + extra 10%.

Planning to eventually reprint parts in ASA.