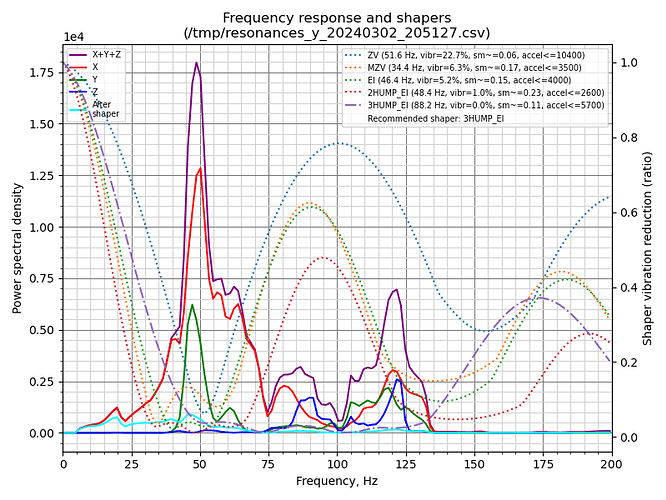

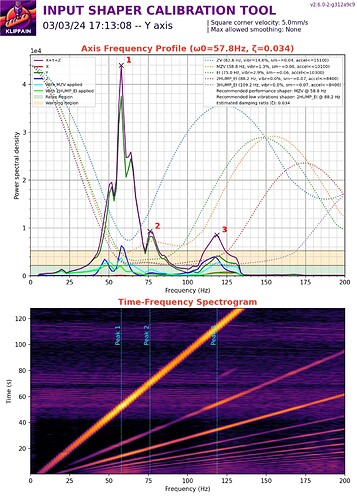

hmmmm… Its not liking something for Y That should be a lot cleaner graph, similar to X

Where did you end up with belt tuning?

Gotta pack some boxes first.

But DAD!!! I DONT WANT TO WORK TODAY!!! LOL

I really don;t want to. I am so curious as to what these insane numbers and tunes do in terms of real world print times and quality.

and…I have some CF PETG sitting here I wanna print.

I agree. And even better for you. You probably know to the min how long your prints take. So you can see first hand a true difference.

I’m betting you will be slowing way down for that LOL. I hate PETG but I have seen several videos where the CF version is supposed to be a lot easier to print.

Better check your square first before you waste the expensive stuff…

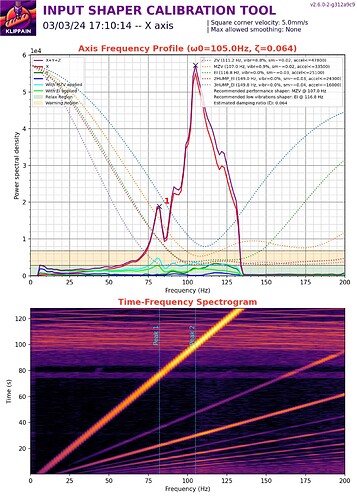

Okay did a belt tuning, GitHub - Frix-x/klippain-shaketune: Klipper streamlined input shaper workflow and calibration tools got them to 96%

Before and after X

Before and after Y

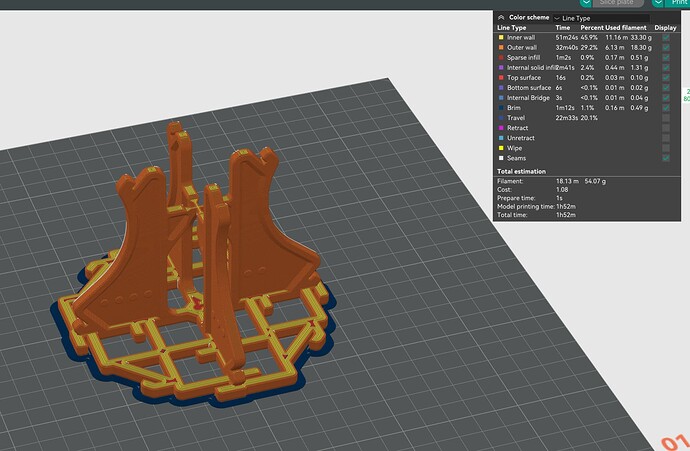

I am going to do a couple prints, before and after the tuning now.

Adaptive mesh is a really solid feature.

Printing at 85mm/s .3mm layers 0.5nozzle that should get my extruder to 90% capacity, 160mm/s travel.

oh…I didn’t realize the regular H2S had that much less capacity than the Revo version…

Glad I realized that. I was starting to talk myself out of the Revo, but it has 3x the max extrusion…

still need to do a little more detailed research I guess ![]()

Shoot I didn’t see that either. I still have the lite version with 45mm3/s but no tungsten.

That said, I only got that number roughly. Once I get more of this tuning done I will do a proper print test to see if I can do more than 16mm3/s Oddly it is a lot more than the 12.8 I was getting with the hemera. Hopefully that is directly after these cubes.

Then when I know my limits, I can run some of the tests again to really dial it in. The second build will not take nearly this long. So much to learn

With your farm I could see having one printer with the tungsten for specialty stuff and maybe run the lite on the others for faster print speed. Like you said you’ve been on those brass nozzles for how long?? So you should be good on your printers for normal pla parts. Depending on how many you plan to switch over that is

I also tried exclude object…neat!

I need to do the tests again. I need some slicer tweaks. I am getting lifting, first layer is too fast. I also forgot I need the filament bowden so it is not tugging on the spool.

And…Okay, Now I want faster.

Yeah I saw that and think that was a great spot to put it.

Lmao time to switch over to the lite. That thing can MOVE some plastic!!! That’s why I got another one lol. Well tried to lol. I also have all the parts to get away from the proprietary nozzle and I have a true bondtech CHT nozzle to try out in one lol

What is the spec volumetric flow on the H2V2s? That is the one you are using?

Biqu says:

H2 V2S: 600mm3/min

H2 V2S Revo: 1800mm3/min

H2 V2S Lite: 2700mm3/min

H2 V2S Lite Revo: 2700mm3/min

Yeah something is goofy about that. I hit a little over 18mm3/s on a print test with a normal nozzle temp and low extruder stepper current. Running another with the same nozzle temp and a normal extruder current, just to double-check. I found teh CHT nozzles are supposed to boost that 25-65%, Bondtech CHT BiMetal Coated Nozzle For RepRap M6 Heat Blocks

Might have to test that.

That’s one reason why I keep bringing up the Revo. I’m in the same place- the flow rate is much higher.

Also the quick nozzle change capability is really nice.

Interesting that the V2S lite and V2S lite Revo carry the same high rating. The lite is a kick butt extruder.

so 1080 mm3 / Min apples to apples.

I’m curious to see your results.

I have the lite non REVO on my V4. At first I was disappointed with it having a proprietary nozzle that only comes in .6mm. But did find a video talking about it and had links to a replacement hotend that takes the standard volcano nozzles. I like the idea of the revo but I just don’t change nozzles often enough to want that high price per nozzle.

As far as the extruder though it’s awesome! I ran a flow test with ASA at 250° and stopped testing at 25mm^3 and it was still keeping up no problem. Haven’t had one single clog switching back and forth from ASA to PLA. It just flat works and keeps up with everything I throw at it. I’ve even started letting it skip layers for infill and it lays it in there nice and thick every few layers. Does an awesome job and speeds up the print time quite a bit. I believe it was @SupraGuy that suggested that in another thread a while back. Nice to finally have an extruder that can flow enough to take advantage of that and the speed the V4 is capable of

Ryan has a lite and I wish he would throw it on the V5 and give it a test run. See what it can actually print at with that much flow.