Did you cut that on mpcnc??

Sendcutsend I think. Looks like it might have a tumbled finish, given the slightly rounded over edges?

I think i remember seeing a reference to that.

It always makes me a little sad seeing people get such good looking results from Sendcutsend. For me, the shipping usually costs more than the parts which makes it somewhat impractical to use.

The CAD has been available this whole time. It is linked in the first post.

+4

Don’t buy anything yet, Wait until I get it running.

Nope to busy.

Nope too busy.

yes!

The parts should be fine on the CNC now. I just don’t have time to spare. This is coming at a time to prep 200 kits and China is back from vacation so full ordering session as well. Normally all that is staggered, 100 here, some ordering 100 there, some more ordering. I should have a friend helping next week for a bit so we will see how much I can get done.

Oh for sure, it’s more things like the belt grinder that James from Clough42 made or stuff for work. They just look so nice straight out of the packaging.

One offs are not cheap enough for me. I would surely do that myself. I ordered 10 sets to make these parts worth it. Even then, 50 is much better. When they drop one off prices, my little CNC business is in trouble.

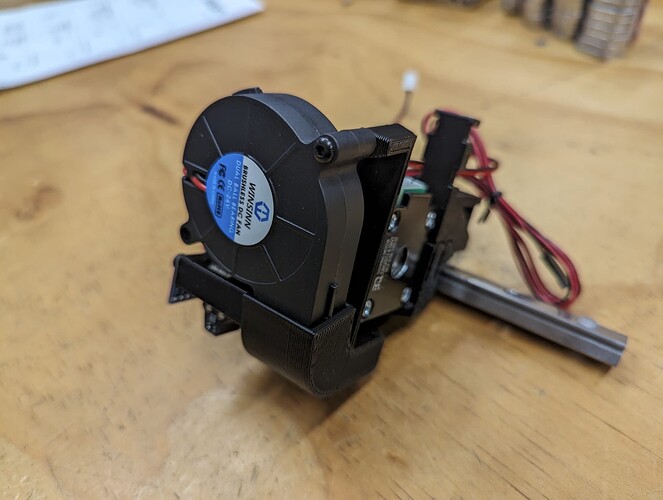

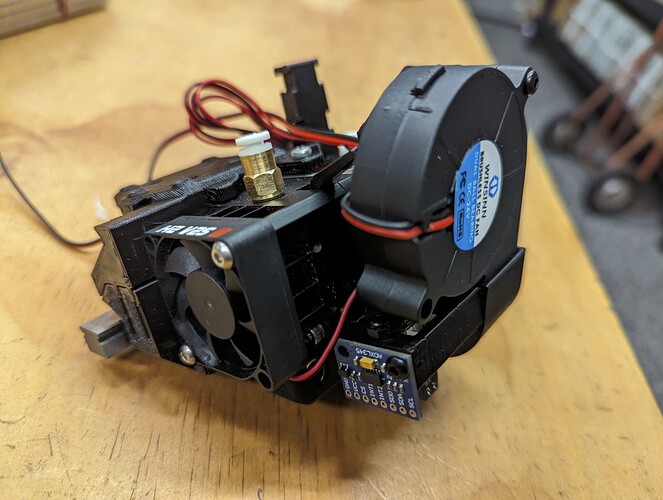

Test print finished. That was pretty easy and even more adjustable. Still able to get to the lever, good airflow, happy with this one.

I will add some of those 3mm slots, and the little wall to hide stuff. Definitely no room for a BL touch this way though.

3 little magnets on the bottom and run klicky!!

Too late now, already model this one up

That servo dock is pretty clean though.

Wouldn’t you tell me “that’s an easy edit. The CAD is already there”. Lol

I’m just picking. It is all looking really good. Excited to see it in motion!

Actually the sandwich mount will still work with that. Can you make one without the BIQU and ADXL mount as an option? The EBB boards have the ADXL incorportated in them.

This looks like a perfect opportunity to learn home anodizing.

HMMM

Nickel plated MP3DP…

New idea for “pro” model.

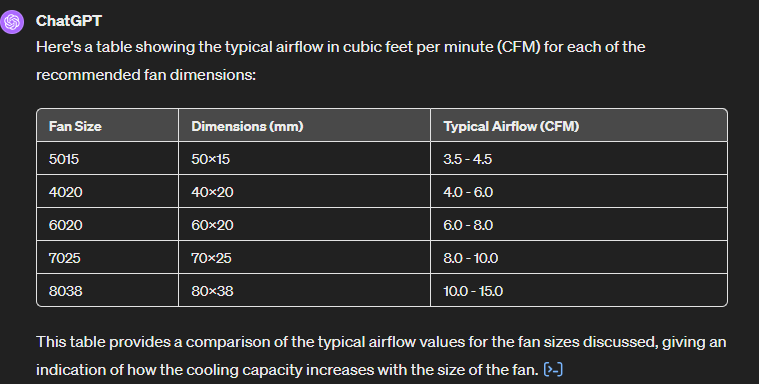

Any MP3DP (or comparably spec’d Printer) owners using something other than one 5015 for part cooling? Was considering higher CFM alternatives recently.

I am going to see how the new tool head does on my E5+ with the cpap blower. If it’s enough difference then I may try to adopt it to work on the V5. Will only need to edit how the belts attach to the tool head and that should be pretty easy.

whoa, that looks SLICK!

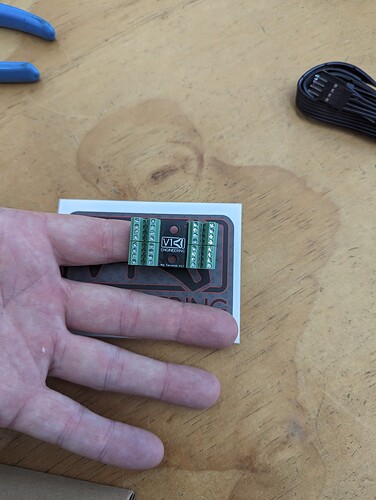

makes that endstop look HUGE!

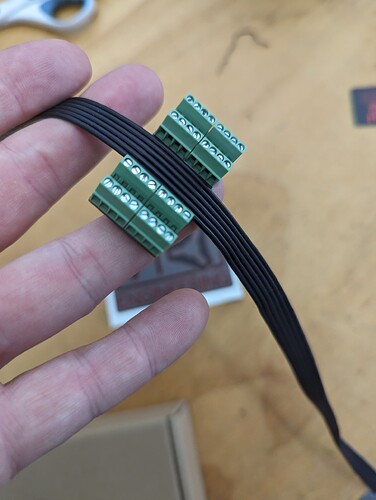

They are pretty small. I am almost done with shipping for today then I will start wiring one up. It should look good.

Here is the wire to go with it.

Is that a metric finger or imperial?