the plugs for the endstops keep coming loose and playing havoc when I try to home anything. Any suggestions for fixing it. The space is really tight on the board

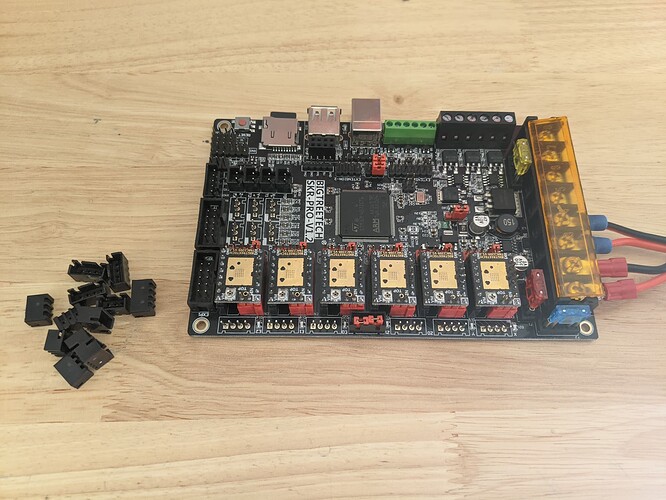

I think some people here use hot glue for this. It shouldn’t really happen though. ![]()

Which board are you using? I’m assuming the wires are coming loose from the board as opposed to the end stop switches themselves?

Which Controller board are you using? Are you talking about the connections at the controller board or where a wire extender is being connected?

Many of the controller boards have a plastic “guard” or keying female socket that doesn’t work well with the Dupont connections that come with the V1E stepper motors and limit switch wiring. The easiest thing to do is remove the plastic portion of the socket on the board. Pull straight up with a pair of needle-nosed pliers. You can then plug the stepper cable or the limit switch connector further down onto the controller board.

There is a picture on this page that shows the SKR 1.2 Pro without the plastic on the limit switch connectors.

Mike

I considered using hot glue or super glue but I thought it would make things worse.

I thought about that too but I wasn’t sure they were removeable.

I was a test engineer for a semiconductor company maybe 25 years ago and I had to deal with tons of cabling mostly molex type. I’m a little rusty at this but I don’t remember things being this loose.

Removing the receiving frame will help the dupont connectors seat more fully on the pins.

Another option is to use locking plugs - you can buy kits of the shells and pins or (and this is my preferred option) pre crimped fly leads. To give you an idea I got 10 sets of 3 wire locking DuPonts with fly leads on 12 day delivery for 3bux

I bought a rig from someone, and it came with hot glue on the board where the wires were plugged in, and I gotta say, I was not pleased with that at all.

I wouldn‘t be either, but there are some who do… ![]()

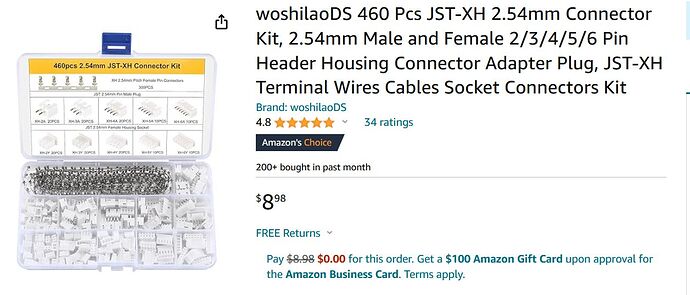

Personally, I put the JST-XH connectors on my wires for the SKR Pro, and it hasnt been an issue.

Dupont connectors can be problematic, but removing the shields works for them and gives an extra mm or so which is usually enough.

I bought the $25 crimper and a multi kit of jsh plugs and solder headers for like $13 and I keep using it. Took a few wasted connectors to get the feel for it, but no regrets. Plugs don’t come out. I’m not a fan of DuPont connectors for anything more than prototyping.

Agree that the JST-XH connectors are the best way. I tried the hot glue and that helped but I still had problems. https://www.amazon.com/dp/B0BZDCGJ32?psc=1&ref=ppx_yo2ov_dt_b_product_details

Are these wires going straight from the control board through a hole in the control box and all the way to the endstop?

If so, add some strain relief inside the control box on the wire so that it can’t be pulled. Depending on the size of the hole the wires are going through, you can either put a zip tie on the wire on each side of the control box wall, or tie a small loop on the wire inside the control box so that it can’t be pulled through the hole. Make the knot far enough from the connector so that the wire from the connector on the board to the knot is ‘loose’.

Not sure if any of this makes sense. The idea is to keep the machine from moving back and forth from causing the wire inside the control box from moving/wiggling.