I had the thought as I’m learning and very new, that it would be cool to build a servo arm to pull up the z probe and have it run homing process automated. Is this just a newb idea or has other people wished this was a thing?

The problem is making it relative to the router bit.

This can be done with tool changers which always place the new tool in with the same offset from the machine, but for those of us who use a wrench on the collet to change tools, something like a BLTouch or servo actuated Z probe have no way to reference the tool Z height. We do it with a 3D printer because the tool doesn’t change height.

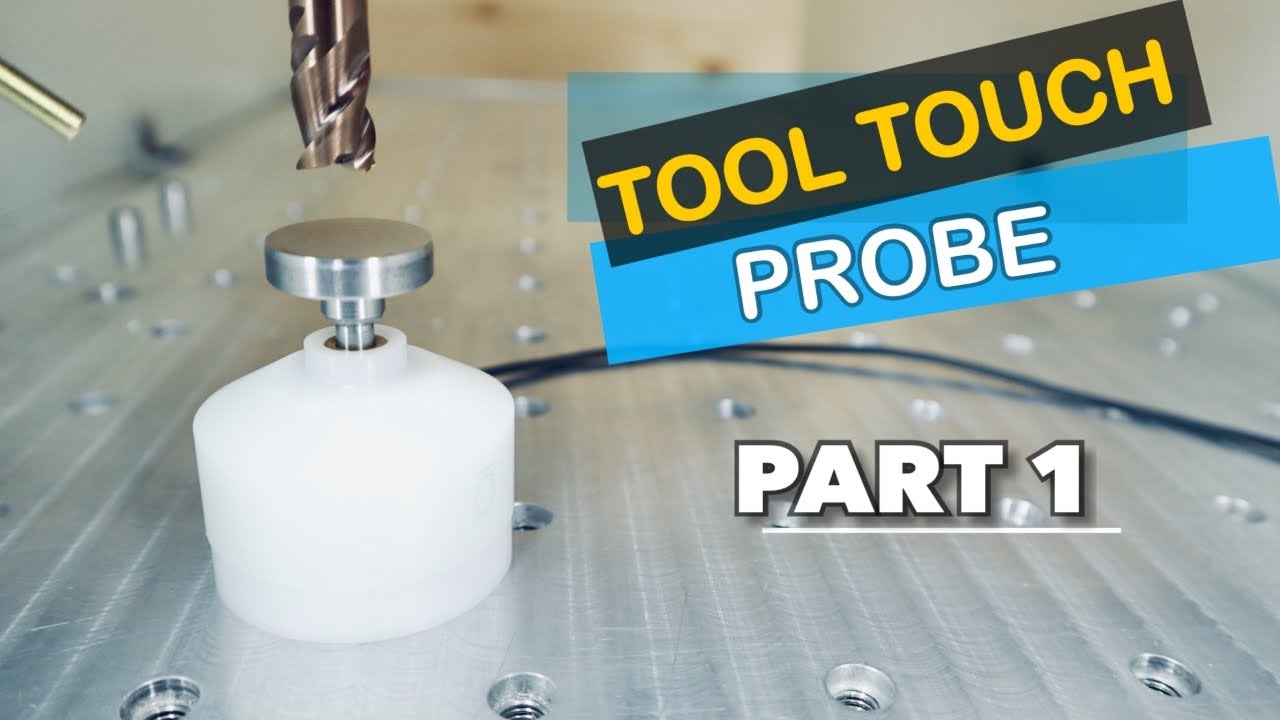

Another technique is to have a permanent fixed-height touch plate within the machine’s work envelope where the newly installed bit can be touched off and a tool offset determined.

The guy I’ve been talking to about his Klipper for CNC macros repo is doing something similar with his machine. Has up a known touch plate for automatically setting the offset during tool changes

is this on a forum, can we all access? I have been really concerned about using klipper for cnc, but you are hitting on some key things. That touch plate may be able to be set up in fluidnc also!

The issue with doing it that way is you do not know where the surface of the material is. The way we do it you know the surface of the material and where the tip of the tool is.

It really depends on the kind of work you do which way will work best for you.

For example an slab of raw wood is going to be all over the place so touch off a random spot and work your way down. With the fixed touch you need to figure out how to measure to the warped board and guess and check.

My opinion is the touch plate on the material (the way most of us do it) is more useful more often. If you are always working with precision materials, plastic and metal, a fixed probe is not all that horrible, other than it takes up bed space.

Nah he and I just text back and forth on discord. I’ll see if he has any interest in setting up a channel about it. I’m happy to help with Klipper if you’ve got questions about setting it up and getting usable gcode out of fusion cam

I had problems with my ramps 1.4 and had to buy something, so i have fluidnc right now. Very interested in this though. I have klipper on a dell with 2 printer instances. Will be keeping an eye on this!

As far as i can ell measuring off the bed only really works if you always cut identical materials or if you’re cutting out parts. You just start your cuts well above any expected material and cut to bed depth. You’ll waste a bunch of time cutting air but material thickness doesn’t matter at that point.

close older topics to help with spambots, and faster new user questions.