Thought I had things worked out pretty well, but I guess not.

Z screws are well lubed, gantry falls freely when power is taken off, run_amps for all motors is set to 0.900, z stub screw is barely threaded, z stub alignment to YZ plate is as good as I can get it.

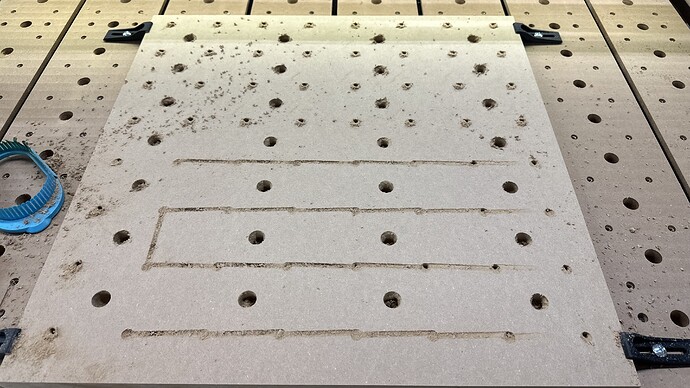

And still I get this…

60 in/min feed rate, 20 in/min plunge, 0.25" single flute upcut bit, 0.25” DOC.

All of the big holes were cut first to full depth 0.75” perfectly, then the smaller holes cut to 0.45" deep until it went off the rails.

Checked the steppers, warm to the touch but not even sort of hot.

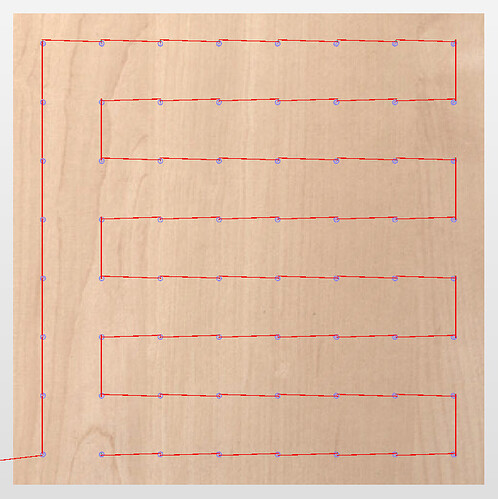

The cut pattern for the small holes looks like

Based on depth measurements, it looks like the Z motor on the left side didn’t raise all the way back out of the workpiece at the top left hole where the gouge starts – that hole is the correct depth, but gouge is .19" deep into the workpiece.

Suggestions on what to look for now?