How are you guys grounding your vac hose? Just wrapping a bare wire around the outside hugging the hose coils, then taking it to the outlet ground? I am losing z steps and I want to make sure I am covering all my bases. I still need to check the lead screw couplers, but it seems to be a consistent z drop across a span of 1220ish mm from left to right.

If you are using the 2.5" hose like a lot of us are, usually the coils around the hose are made from a metal wire, and you can attach a wire to the end of it and run to ground.

Also make sure you have lubed the lead screw well, that can and will cause binding if not lubed properly.

I bought some uninsulated stranded from lowes and just run it through the hose and then to the outlet

I haven’t bothered with insulation and haven’t (so far) noticed any issues with static. (Of course, it’s spring in the Midwest and humidity hovers at 70% or higher for the next several months, so I probably won’t have any issues till winter…)

If you’re going to use a wire, I’d run it inside the coil as @Nathan_Doty suggests.

Far better to ground the coil itself. By nature of insulators, you only bleed off charge from the area very near the drain wire. That said, even a straight single wire is better than none at all.

Just a little follow up, the hose I have is all plastic, I wrapped the ground wire around it and took it to the ground of the power I am powering my LR with. This did not change anything with me losing z steps, I also removed the vac hose and left it off and I am still losing z steps. I am currently taking the leads out and checking to see if anything stands out, but nothing looks off so far. I’m going to reinstall everything and try to run the same file again. Also the z stepper motors were running about 88-90 *F

I’m not sure if this will really do anything to dissipate static. I ran the bare wire INSIDE the hose, and attached it to a bolt running through the hose, where I could attach another wire leading to a ground point.

What’s an appropriate ground point? I was thinking maybe a ground terminal on my controller, or the PSU

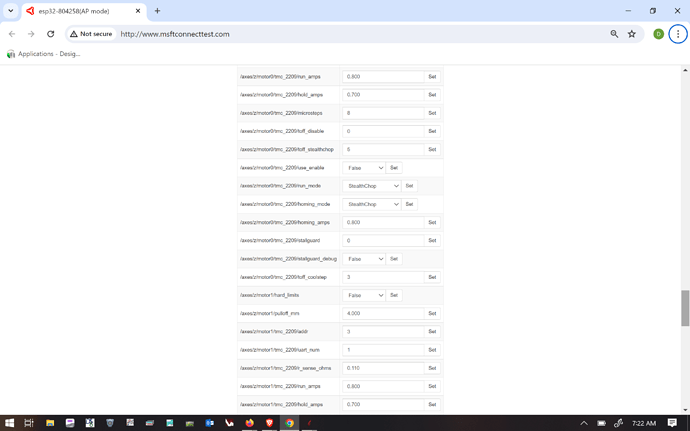

First of all: can you show us your Run_amps part of your z axis in the config. Yaml?

I will probably do that after I find out what is going on, for now I have the vac turned off and hose disconnected and I’m still dropping z.

That’s the worst possible place.

It should go to AC ground or shop ground bar if you have one.

You want it kept way away (electrically) from your controller board electronics DC returns.

Do you see anything in the FluidNC terminal window when this is happening? We may want to see that, or better still have FluidTerm running while you’re testing so we can see any log / error messages.

I did not think of that, but this afternoon when I run it again I will watch it, and save the log.

Also, I am using Aspire, the only thing I edited in the GRBL PP inside of Aspire was adding M62 P0 to turn on the spindle at the start of the job, and M63 P0 at the end to turn the spindle off. I have been using GRBL since the LR2 with aspire and i do not recall it giving me any issues. I did run one test of the same file using Estlcam and it did not look to have much z loss if any. I only did the Estlcam test once as I ran out of time. I created the spoilboard file in Aspire and it didnt give me any issues, but it also didnt have a lot of up and down movements. I attached the test gcode from one of the times when my z kept getting lower.

[Edit- The more I think of it, I am going down further than it should be, so I’d say I’m gaining z steps instead of losing z steps.]

TEST.gcode (19.4 KB)