Since I only check this forum sporadically, let me go ahead and give you the pinouts for the Rambo board that you can use to drive the IoT relay.

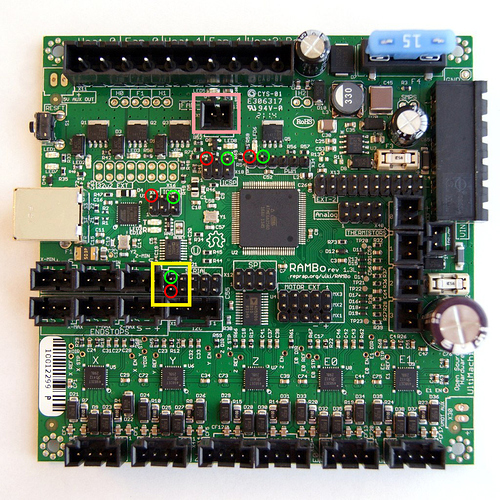

To start, you are looking for pins that are always on when the board is powered up. The two in the yellow square I’m absolutely sure of since I use them for something on my MPCNC. The other circles represent likely power out pins based on the schematic. Note I have limited electronics experience, so you will need to test pins other than the ones in the yellow square with a multi-meter before using. The peach square are the pins I use to control my IoT relay using GCODE M106 and M107 commands. There are other forum posts that cover using Fan2 to control devices. Note you want to be careful to never short out the pin pairs I’ve listed when the board is powered up…you will likely damage the Rambo board. Also the IoT relay connection is polarity sensitive, but, based on other posts, getting it wrong only results in the IoT relay not working…not damage to the board.