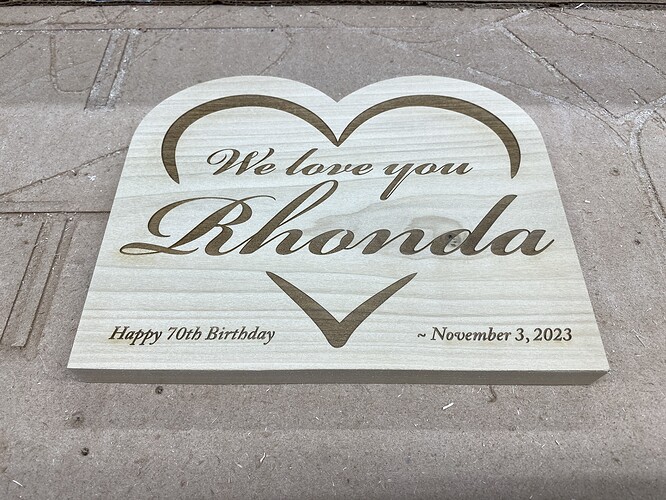

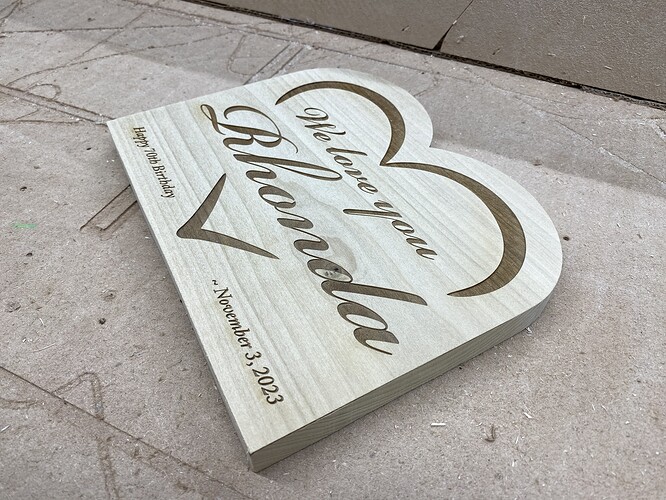

Early this morning I made this from a slab of Maple hardwood using a combination of my 100-watt CO2 laser (for the engraving) and my beefed-up 1.5HP bandsaw (for the outer profile shape cutting). The design is my own work.

Looks great. I’m always amazed by the fact these lasers provide so much visual depth

Very nice Doug.

This was done at a speed of 300 mm/sec running at a power rating of 70%. One pass.

A 100W CO2 laser, at least mine, can cut through 1/4” thick of hardwood, I’m talking Red Oak, in a single pass. It’s a workhorse for me.

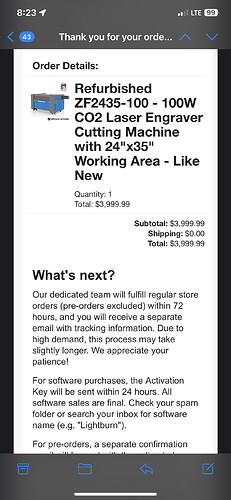

Scared to know the price of such a unit. Hopefully get mine running tomorrow or Tuesday and can start selling some projects to get a laser. Probably my top upgrade (that and someone’s ![]() floating dust collection)

floating dust collection)

The talk over in the recent DIY CO2 laser thread is that you can probably build one this powerful for less money than I paid for it. I think that may be doable, but there is a lot to this that has to be taken into account if you’re going to match the performance and speed of one of these commercially available units. It is beneficial when the body is heavy and rigid because this allows maximum speeds without the frame shuddering or vibrating. This thing weighs like I think 600 pounds or more, if I remember correctly. It is a beast.

![]()

I can lift that…later: ![]()

Spending $4k is one thing. DIY laser machines is one thing. But I have built enough machines to worry that I would spend $3k on it and have some very frustrating problem and not be able or willing to fix it.

I have always said that is a key feature of the V1CNC. If it didn’t work, I would be able to accept that kind of loss. I could risk $500 for the experience and possible gain of building a CNC machine. I could have done it 15 years ago, but I wasn’t willing to risk $2k.

Yes, exactly. And, as we know, getting things really “right” for laser raster work at high speed, is challenging. You need good hardware, good frame, good control board, and good software.

Several who recently built the Mostly Printed 3D Printer (MP3DP) have found that building a CoreXY printer is a much more complex and much more challenging build than, say, a LowRider or a Primo MPCNC.

I am fairly convinced that getting a large, powerful DIY C02 laser to really perform well, is also a more complex and challenging build than might be suspected, for some reasons different from the CoreXY printer builds, and perhaps some reasons similar or the same.

My store-bought OMTech laser can raster burn perfectly at 500 mm/sec. That’s 30,000 mm / minute!

The steppers are massive. The linear rails are massive. The frame is substantial. The pulleys and drive components are majorly beefy. The rigidity is amazing. The software is the popular GUI of the famous Ruida control board. It’s not a small, cheap Ruida, but rather a big nice one. These big nice Ruida boards are so popular for a reason.

I’m a major fan of DIY machines. I know it can be done. But even after building a LowRider, and seriously, seriously considering building a CO2 laser, I opted to buy instead, and I’m really glad I did.

Another consideration in the “build vs buy” dilemma comes as one starts thinking about what they’re gonna be leaving their kids when they’re gone. I’ve had a ball building DIY machines over the years to satisfy my own itch but now that I’ve reached that age and spent time trying to get all my affairs in order… there’s not a DIY machine I’ve ever built that has the fit, finish, and documentation of a store-bought machine. My house has been cluttered for years with machines I’ve built and while everyone has oohed and aahed about the things I’ve done with them… they’re not machines that anyone in my family would ever be able to use and maintain. As a result, for my kids, they’ll only be so much clutter and difficult to sell or dispose of.

As most of my itches to build stuff have been somewhat satisfied at this late date – and not to slight Ryan and my many DIY friends here – I’ve in the past few years decided to buy the machines that pique my interest. I live modestly and alone and now have the “disposable” income to buy some nicer machines… and they’re certainly better built, easier to use, and more capable than anything I could ever build… and they come with manuals! And I’ve had a blast learning and doing some things with them that I never dreamed I’d ever do… and would, most certainly, have been beyond the capabilities of anything I could have ever cobbled together from my junkbox. As a result, I’m now free to dismantle and box up the DIY machines I’ll never use again and, hopefully, leave my kids fewer headaches and less clutter to dispose of. And, quite possibly, a machine or two they might actually find useful… ![]()

Not a biggie for many/most here… just another rather unique and quite personal consideration.

– David

This makes me think of books vs magazines. If you’re clearing out someone’s belongings, a collection of magazines has served their purpose. They are not worth sorting through. Their purpose was temporary entertainment. Maybe some of them have good material that the owner referenced, but it isn’t valuable to most other people. Magazines go straight to the recycle bin.

A shelf of books can have use for a long time. There are good books and bad books and you might need to filter them to donate or sell or something. You can search on ebay or amazon and see how much any book is worth.

The DIY machines you’ve made don’t have much use for most people. You’d have to find a special person who would appreciate them, and most of those people can make their own (or already own some). Their value was to scratch that itch you were talking about. The journey was the destination. They are were worth every penny to make, but they don’t have future value with anyone else.

The buy machines didn’t give you as much entertainment (or at least not the same) but they do come with manuals and you can find their price on ebay. So they do have value and reselling is a straightforward operation.

My unsolicited advice is to buy a magazine if you want, and don’t worry about the future value. The journey is the destination. If you only want to read books, that’s fine. But if you get that itch, go for it. It should be clear to your kids the value was already used up.

I agree with this. I didn’t build these machines with any consideration for what I’d be leaving my kids. And I did indeed enjoy building them and wound up with a house full of machines… and so much clutter that I could never share the house with another person. While I can live with it, it’s only so much mess someone else will have to deal with after I’m gone.

My late wife was a shopping addict and hoarder… and amassed such a mountain of stuff that it was truly a painful experience trying to get rid of it. Literally years of yard sales, charitable donations, give-aways, trips to the dump, etc… and even now there is still brand-new boxed items rotting in my outbuildings. The brunt of all this activity sadly fell to my daughter and daughter-in-law and a few of my wife’s friends… I was overwhelmed by it all. It was genuinely an excruciating, exercise that still leaves remnants and painful reminders to me and my kids, years later. And, while not as bad as my wife, I, too, have unintentionally managed to accumulate a bunch of stuff that will be a pain to dispose of. And I really don’t want my kids to have to deal with anything like that again.

– David

I’ve told my kids that if it comes to it to just get the junk haulers out. They don’t have any interest in woodworking or tooling. There was a brief spate with 3D printing, but now that they’re done with what they found on Thingiverse, the 2 printers I made for them sit idle. So my 3D printers, lasers, panel saw and CNC machines will probably end up scrapped. Most likely the jointer, table saw, drill press and lathe too. Lots of tools, but the kids aren’t interested in them.

They do like other things that I’ve made for them with those tools, but I don’t think they really appreciate what went into them.