I’m guessing the F2500 is a rapid movement. If you are using the personal/free version of Fusion 360, then I’m surprised to see it. It may be an artifact of Fusion 360’s recent changes to its personal/free version combined with the Martin DB Post Processor. Most people on this forum that use Fusion 360 use the guffy post processor. The values are in mm/min.

Ok. I can’t get Guffy’s PP to work, the gcode file just doesn’t appear. Maybe this suggests a problem in my initial set up?

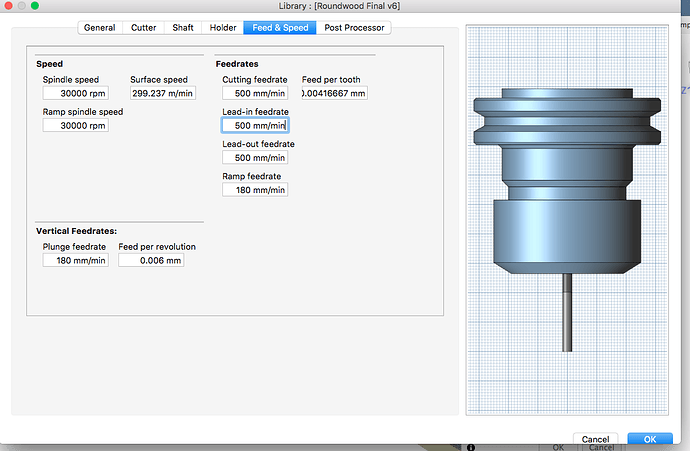

The Z feedrate is indeed coming from the feed per tooth, in turn from the cutting feedrate. 2500 / 60 / 10,000 = 0.00416. Why I have to divide by 10,000 I have no clue!

I think I’m having the same issue as this guy which you both commented on. I’ll try the M203 and report back.

The rapid feedrate from Fusion is probably also throwing my actual print time off, which I’m keen to refine. Or is this always going to be different and I shouldn’t worry.

No. You only have to run it once. After that the new values are saved in the EEPROM. You can type this g-code in from Repetier-Host. You can type it into a text file saved with a .gcode extension and run it of an SD card. Note that the value for the M203 is in mm/s not mm/min.

Ok thanks. So adjust the mm/s value to mm/min? Then run and it’s done.

I don’t have advice on speeding things up. I only cut a few, smaller terrain maps. There are many active people on the forum that have far more cutting experience than I do. I would suggest you open a topic just on this issue. Note the 4-flute end mill is raising red flags for me when combined with the DW660.

Thanks, I’ll open up a thread as soon as I sort this gouge issue.

The map is quite small, 250mm x 250mm. My machine is about 900mm square, giving about 450mm sq print/milling area.

The red flags for 4-flute - are less flutes better? For chip load on a heavy pass I assumed the more teeth the better. I’m not using it for a finishing pass.

When I run the code line-by-line, the machine didn’t gouge out the piece. It went straight to the starting corner. I have no idea what this means. Could this be a G1 linear move problem? As in the machine is moving along the axes rather than X & Y at the same time for a diagonal move? It’s all at the start of the operation, no trouble otherwise.