Release V3.0 (Beta 3) of the Flyfisher604 F360 post processor is available.

Beta 3 - addresses an issue that prevented coolant commands from working.

Beta 2 - addressed issues related to Laser On and Off commands not working as expected.

Beta 1 - addressed changes related to how F360 passes parameters to post processors

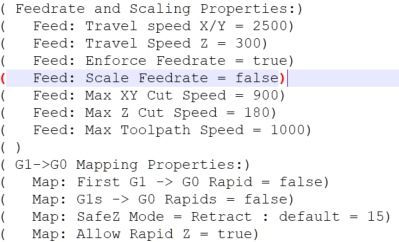

The Beta 1 update required a complete rework of the parameter handling within the MPCNC post-processor as Fusion 360 updated the interface and invalidated the old mechanism.

The changes required updating many parts of the post-processor and were not simply limited to a parameter display issue. Anywhere parameters were used, the post-processor required modification. Parameters control which parts of the post-processor run and the values used to transform the internal F360 codes to GCode.

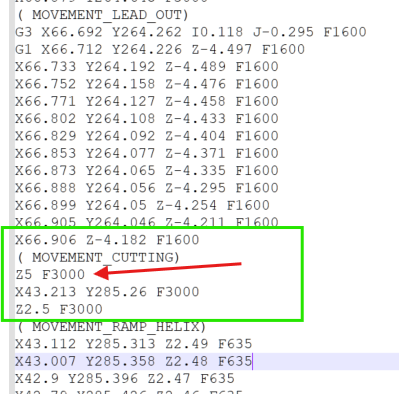

Simple testing has been done, but no extensive testing with different sets of parameters has been conducted. Please review all generated GCode closely.

All testing was done in mm. However, the F360 documentation indicates that the way inches are handled has changed. When the post-processor was updated, no attempt was made to understand or accommodate these documented changes. Assume that inches do not work, and test extensively any GCode generated with inches selected.

WARNING:

- This is BETA code.

- Review all generated GCode carefully.

- Use at your own risk.

Installation

Unzip MPCNC v3.0 (Beta 3).zip and install MPCNC v3.0 (Beta 3).cps using the F360 Post-Processor setup dialog.

Success and Errors/Issues

Please post successes and errors/issues to this thread so the post-processor can be confirmed to work and issues resolved.

MPCNC v3.0 (Beta 3).zip (14.7 KB)