No, I just have the basic one mate.

I was suggesting moving without the router on, just in the air.

Thanks for staying with me on this.

I did what you suggested and moved it around manually. It seems perfectly accurate in X and Y that way.

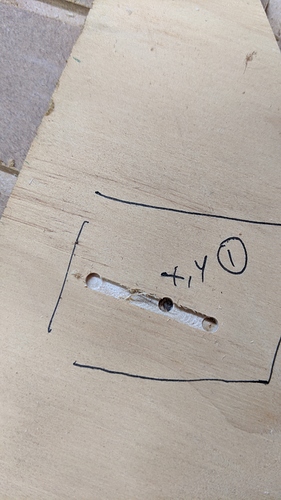

I did 100mm holes about 3mm deep across the table for 600 mm and then went down the Y axis about 600, across and back etc and finally got back to the home point after peppering the sheet with holes and the final 2 holes bracketed my starting point by about 1mm. See this photo.

I started with the centre hole marked XY and then did a manual drag of the router from the top hole, across XY and then to the hole on the right in this photo. It is not perfect but it is pretty close over all the moving. I guess the bit of misalignment is due to the movement of the gantry in the X plane.

The errors in X have been consistently about 3mm. Not seen here.

So. It must be in the code.???

So what do you think I should do now? Can you think of a Gcode exercise that could be diagnostic?

I was thinking of drawing a ruler in FS 360 and then cutting it across the width of the table to a depth of say 3mm with markings every 50mm or so?

Rob

Well, looking through all of this I am stumped.

Best guess I have is update your firmware. You are using arcs so maybe you have old firmware before we fixed them. You need 414 or newer (maybe it was 415…) we are at 425-6 now.

Humor me… Trying to visualize what’s happening.

Low Rider. When you run your job on 12mm stock, your toolpaths end up a consistent ~3mm off in one X direction (across the gantry, not along the table). How many passes does it take to get that far off? Is it a consistent amount per pass, or per mm of stock, or is it just always that amount, regardless of passes or total depth of cut?

There is a second thread, turns out it was a loose pulley!

D’oh! Well, if you hadn’t replied, I wouldn’t have been fooled into thinking it was still an issue!