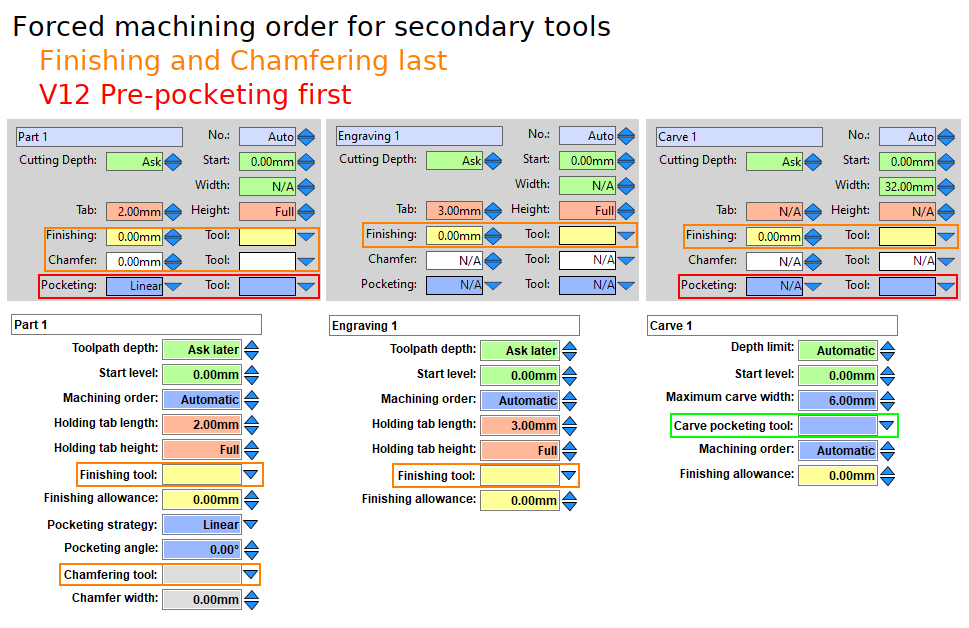

Estlcam has what I call primary and secondary toolpaths. Paths that are directly set by the user are primary toopaths and those indirectly set via the primary toolpath properties window/pane are secondary toolpaths.

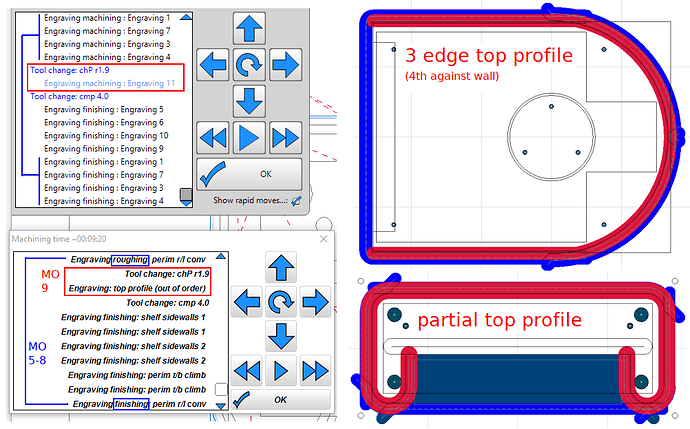

All secondary finishing and chamfering tool paths are machined last, after all primary paths have been machined. The expected finishing pass follows roughing pass will only happen if there are no more primary paths to cut.

The problem with secondary paths that follow primary paths is that there are numerous possible scenarios where secondary paths need to be machined before primary paths. The simple examples are primary profiling paths getting cut before the edges being profiled have gotten their finishing pass.

With v12 all secondary Pre-pocketing paths are machined first, before all other tool paths. Pre-pocketing is a new option for Holes, Parts and Carves. Carve Pre-pocketing replaces the v11 Carve pocketing tool.

The v11 Carve pocketing toolpath is not like other secondary toolpaths because v11 Carves are machined in full (per set Group and Machining order). This is what I expect when Grouping paths and setting a Machining order.

With v12, anyone who does two-side machining and wants to machine anything on the backside - drilling for locating pins or feet, cutting hardware pockets/t-slots, customized engravings, etc. - before machining a carve pocket on the face is going to run headfirst into the Pre-pocketing paths being forced to the start of the program/G-code.