I have been wanting to upgrade this printer to use a direct drive extruder for quite a while. I have been waiting for a lightweight extruder, so I could do away with the Bowden extruder. I have never liked Bowden. I am hoping the Sherpa Mini is lightweight enough. I have not ordered one yet as I wanted to see how it worked out in a design first. Think I have the design about as good as I can get it. I have seen this extruder used on a FLSUN delta, so seems like this work on this Delta also. My effector is a little smaller than that one with an Effector offset of 25mm. The arm spacing of 40mm seems to be the same as the FLSUN.

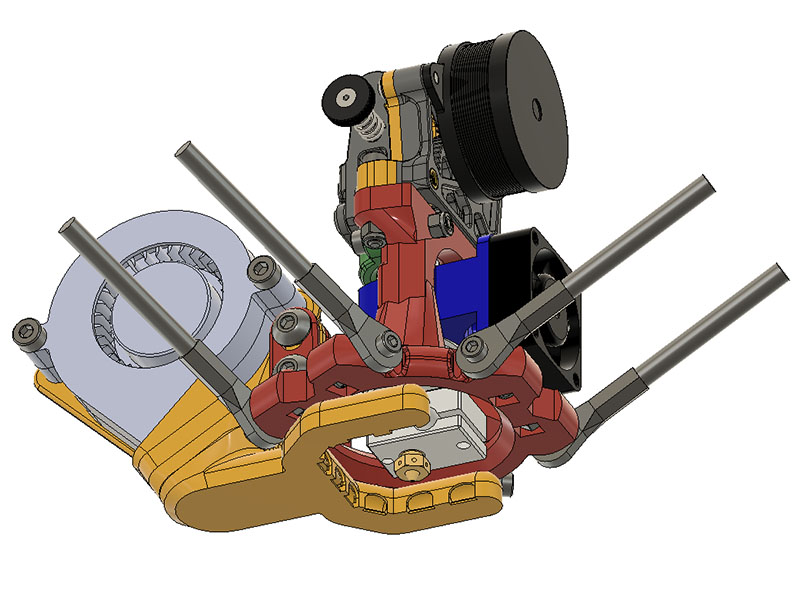

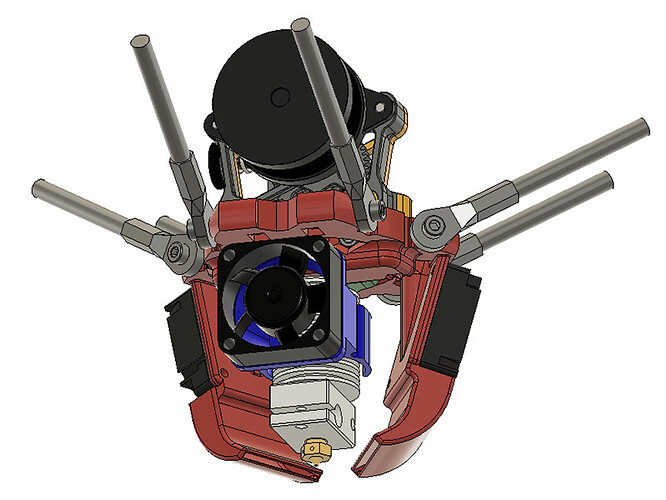

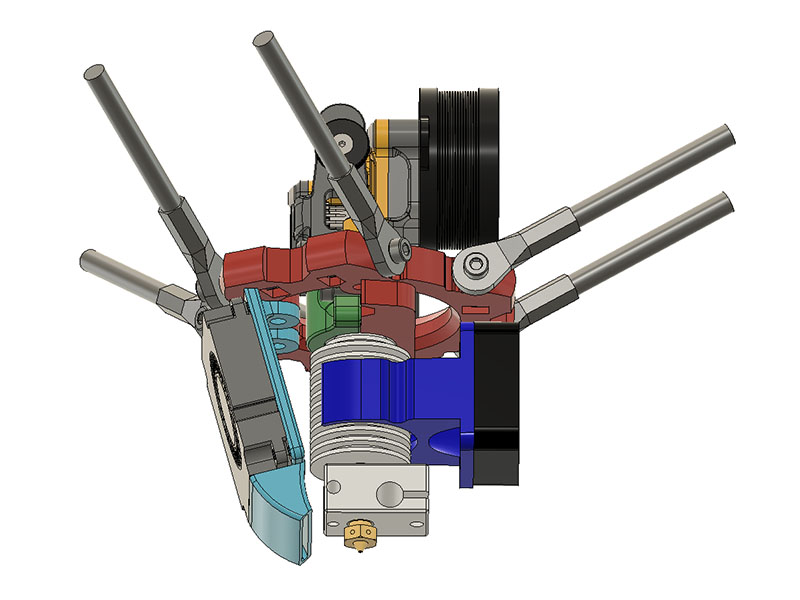

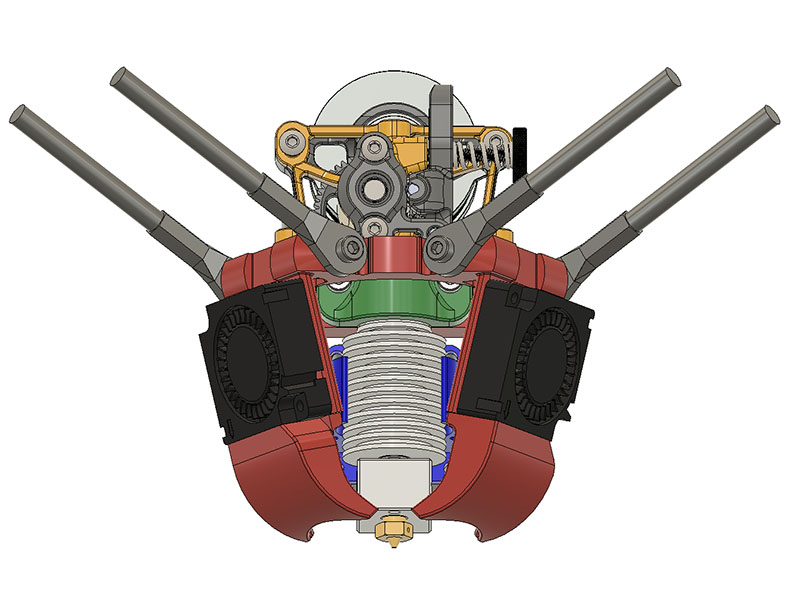

I remixed the effector design I had done before for this FT Delta & the fan duct from a couple of bed slingers I have. My previous design was done in openscad, so I redid it in fusion 360 to make my life easier. The fan duct took the longest. My biggest concern is whether the motor will have too much weight on that side. I initially put a 5015 blower cooling fan on opposite side to help with that, but someone on the discord pointed out that fan was sticking out too much and would hit something. I plan to use an E3D V6 hotend, but might use the E3D Lite6 that is currently on there if it still works. I had looked at originally having the extruder resting on the effector but wanted to start with a design I already had & then go from there. I kind of forgot about that after getting so caught up in the design & someone on the Annex Engineering discord pointed that out & brought me back from that rabbit hole. Here is the 1st design where I just essentially used my previous design that only had the hotend attached.

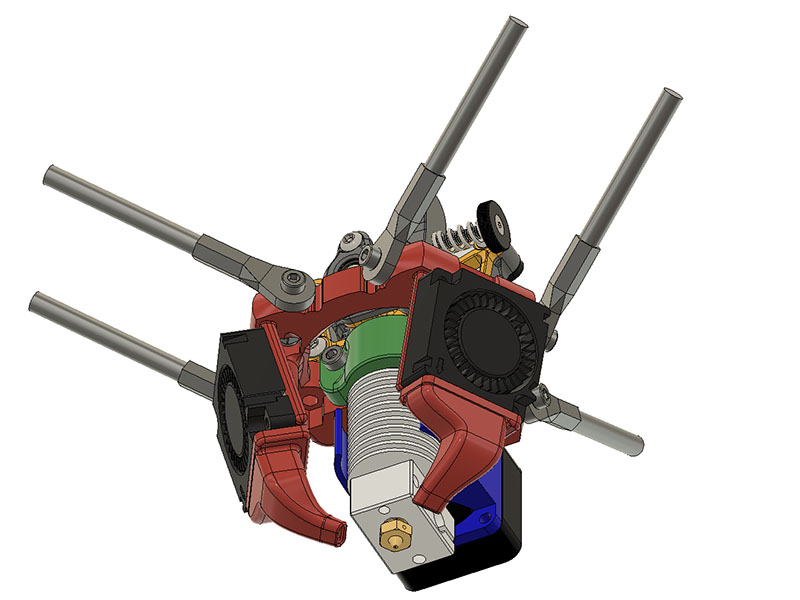

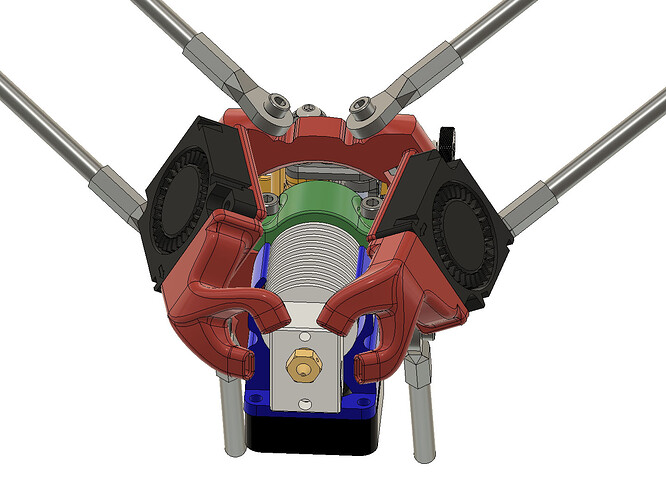

I started looking at the cooling fans they were using on FLSUN QQS-Pro One Piece Extruder Mount for Sherpa Mini (Remix) by SpaceSputnik - Thingiverse . It doesn’t mention which fans they use, so I looked at the Voron designs to see what they are using. They are using 3010 fans on the V0 model. I made a design to use 2 - 3010 blower fans or 1 - 4010 blower fan. I have only used the 5015 blower fans as cooling fans & have not used th3 3010 or 4010 fans. Looks like I have room to put a 4020 blower fan in where the 4010 fan is with little modification to the design. I incorporated the 3010 fan mounts into the same part as the effector & made the 4010 mount a screw on. Here are those 2 designs.

I had the idea for curving the outlets on the 3010 blower fans. Seems like that might spread the air more evenly.

Anyone have thoughts on either of these fans or ideas to make this design better? I have not ordered the extruder or the fans yet, but will probably order a couple of the WINSINN 3010 blower, a 4010 blower & a 4020 blower. I have 12v heatbed on this machine, so will need to stick with 12v fans. I’m also planning to use a BTT SKR 1.4 board since I have a spare one of these.