Hey everyone,

Figure I would do a quick write-up to help anyone else that might be looking for this information. I wanted to make the switch to GRBL, but was having issues with the Rambo 1.4 board. I tried a few Fusion360 post-processors and everything would start off fine, then all of a sudden the cutting tool would fly off in the positive x-axis direction uncontrollably which essentially destroyed the workpiece.

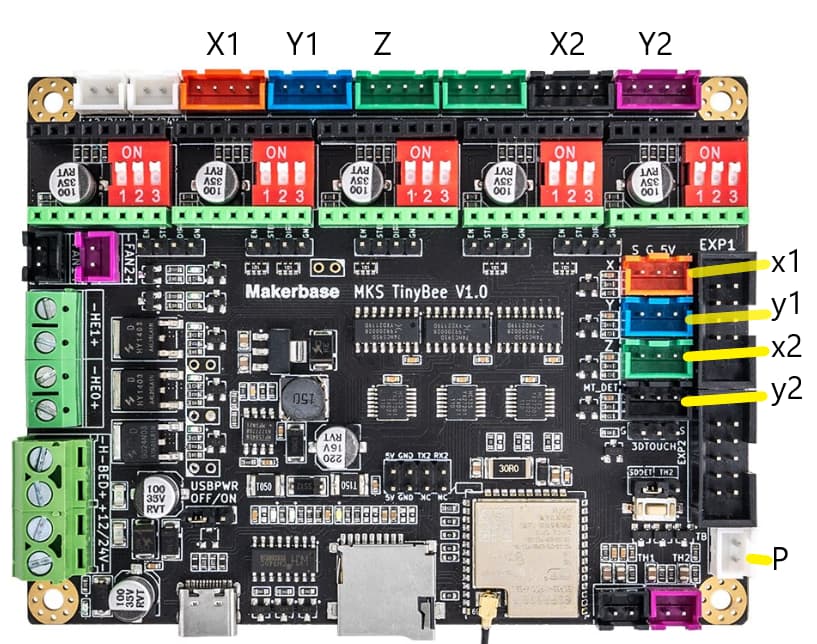

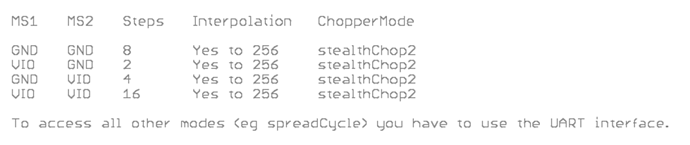

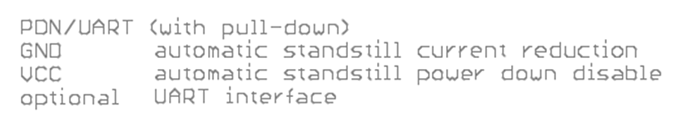

I bought an MKS TinyBee along with 5 TMC2209 stepper drivers. I was able to flash FluidNC without any issues, and could connect wirelessly to the FluidNC web portal. The trouble came when trying to get the configuration file dialled in so that I could get the correct movement from the CNC, as well as use gSender which I have preferred for controlling my MPCNC. I didn’t have any luck with the sample config files, whether it was for the TMC2209 steppers, or specifically the example for the TinyBee.

A few notes that I only figured out after several days of trouble shooting, in the hopes that it will help others.

-

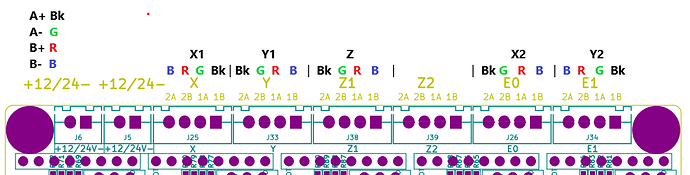

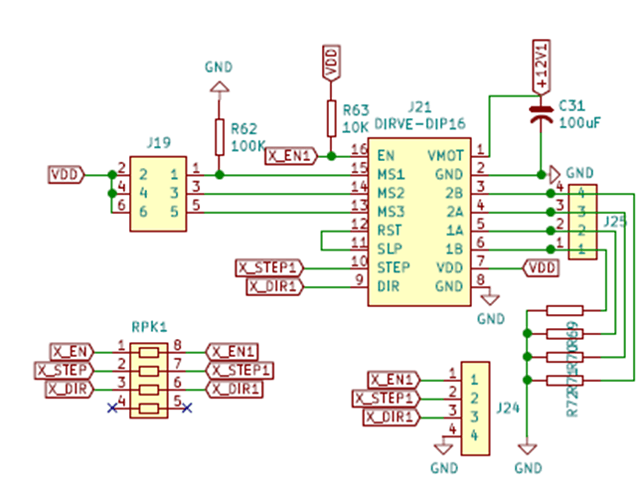

When you look at the board diagram here you can see that there are six motor outputs: X, Y, Z1, Z2, E0, E1. What took me a while to realize is that Z1 and Z2 are run by a single stepper driver, meaning that you can drive two stepper motors with a single stepper driver, but you can’t control these independently. This is why the Z1 and Z2 plugs are both the same colour.

-

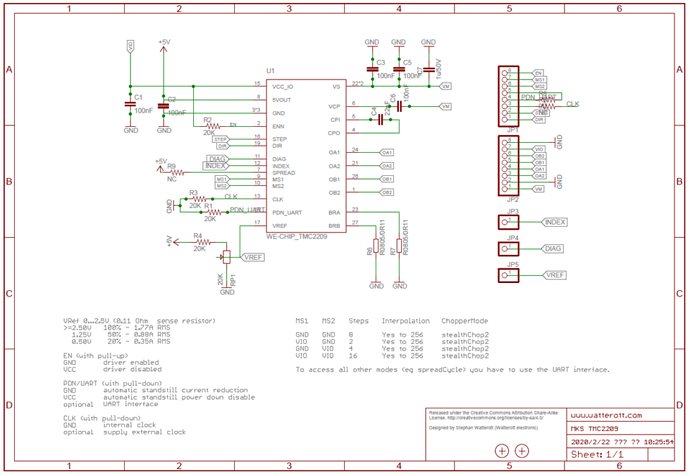

I don’t understand the details behind all of this, however it seems that GPIO pins over and above around 32 or 36 (I can’t remember which one) have to be addressed through the I2SO system, instead of the GPIO referencing. The following are the I2SO pins to use for each motor port:

X Disable Pin: I2SO.0

X Step Pin: I2SO.1

X Direction Pin: I2SO.2

Y Disable Pin: I2SO.3

Y Step Pin: I2SO.4

Y Direction Pin: I2SO.5

Z1 and Z2 Disable Pin: I2SO.6

Z1 and Z2 Step Pin: I2SO.7

Z1 and Z2 Direction Pin: I2SO.8

E0 Disable Pin: I2SO.9

E0 Step Pin: I2SO.10

E0 Direction Pin: I2SO.11

E1 Disable Pin: I2SO.12

E1 Step Pin: I2SO.13

E1 Direction Pin: I2SO.14

Other important pins required if you’re using dual endstops for the auto squaring feature:

X Endstop: GPIO.33

Y Endstop: GPIO.32

Z Endstop: GPIO.22

MT_DET: GPIO.35

The way I have my MPCNC physically wired is as follows:

X0 Stepper: Wired to the X-Motor plug.

X1 Stepper: Wired to the Y-Motor plug.

Y0 Stepper: Wired to the Z1-Motor plug.

Y1 Stepper: Wired to the E0-Motor plug.

Z Stepper: Wired to the E1-Motor plug.

X0 Limit: Wired to the X end stop plug S and G pins.

X1 Limit: Wired to the Z end stop plug S and G pins.

Y0 Limit: Wired to the Y end stop plug S and G pins.

Y1 Limit: Wired to the MT_DET plug S and G pins.

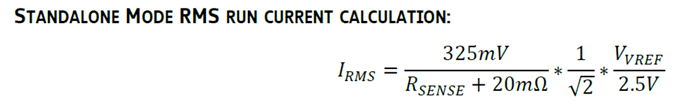

I’ll add my configuration file at the bottom. Again, this is using TMC2209 stepper drivers (5 of them). I am able to auto-square in both the X and Y axes. I haven’t tried implementing a Z zeroing tool, however I would imagine if you wired it up to the 3D Touch plug and used GPIO.2 it should work.

board: MKS TinyBee V1.0_001

name: MPCNC

kinematics:

Cartesian:

stepping:

engine: I2S_STATIC

idle_ms: 255

pulse_us: 4

dir_delay_us: 1

disable_delay_us: 0

axes:

x:

# X

steps_per_mm: 100.000

max_rate_mm_per_min: 2000.000

acceleration_mm_per_sec2: 500.000

max_travel_mm: 325.000

soft_limits: true

homing:

cycle: 0

positive_direction: false

mpos_mm: 0.000

feed_mm_per_min: 300.000

seek_mm_per_min: 5000.000

settle_ms: 500

seek_scaler: 1.100

feed_scaler: 1.100

motor0:

limit_neg_pin: gpio.33

hard_limits: true

pulloff_mm: 2.000

stepstick:

step_pin: I2SO.1

direction_pin: I2SO.2

disable_pin: I2SO.0

motor1:

limit_neg_pin: gpio.22

hard_limits: true

pulloff_mm: 2.000

stepstick:

step_pin: I2SO.4

direction_pin: I2SO.5

disable_pin: I2SO.3

y:

# Y

steps_per_mm: 100.000

max_rate_mm_per_min: 2000.000

acceleration_mm_per_sec2: 500.000

max_travel_mm: 220.000

soft_limits: true

homing:

cycle: 1

positive_direction: false

mpos_mm: 0.000

feed_mm_per_min: 300.000

seek_mm_per_min: 5000.000

settle_ms: 500

seek_scaler: 1.100

feed_scaler: 1.100

motor0:

limit_neg_pin: gpio.32

hard_limits: true

pulloff_mm: 2.000

stepstick:

step_pin: I2SO.7

direction_pin: I2SO.8

disable_pin: I2SO.6

motor1:

limit_neg_pin: gpio.35

hard_limits: true

pulloff_mm: 2.000

stepstick:

step_pin: I2SO.10

direction_pin: I2SO.11

disable_pin: I2SO.9

z:

# Z

steps_per_mm: 1400.000

max_rate_mm_per_min: 200.000

acceleration_mm_per_sec2: 300.000

max_travel_mm: 80.000

soft_limits: false

homing:

cycle: 0

positive_direction: false

mpos_mm: 0.000

feed_mm_per_min: 300.000

seek_mm_per_min: 1000.000

settle_ms: 500

seek_scaler: 1.100

feed_scaler: 1.100

motor0:

hard_limits: false

pulloff_mm: 1.000

stepstick:

step_pin: I2SO.13

direction_pin: I2SO.14

disable_pin: I2SO.12

i2so:

bck_pin: gpio.25

data_pin: gpio.27

ws_pin: gpio.26

spi:

miso_pin: gpio.19

mosi_pin: gpio.23

sck_pin: gpio.18

sdcard:

cs_pin: gpio.5

card_detect_pin: NO_PIN

control:

safety_door_pin: NO_PIN

reset_pin: NO_PIN

feed_hold_pin: NO_PIN

cycle_start_pin: NO_PIN

# EXP1 BTN_ENC

macro0_pin: gpio.4:low:pu

macro1_pin: NO_PIN

macro2_pin: NO_PIN

macro3_pin: NO_PIN

macros:

startup_line0:

startup_line1:

macro0: $SD/Run=lasertest.gcode

macro1: $SD/Run=home.gcode

macro2:

macro3:

coolant:

flood_pin: NO_PIN

mist_pin: NO_PIN

delay_ms: 0

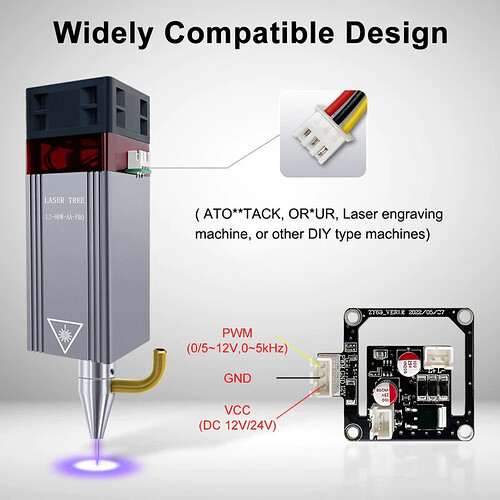

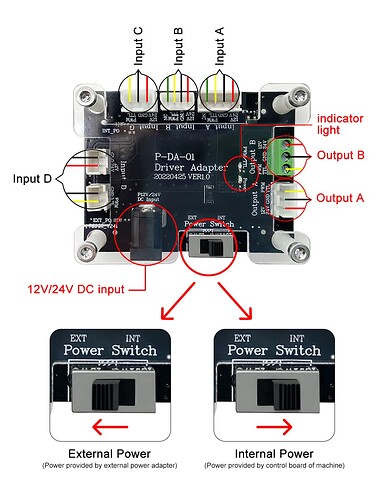

Laser:

pwm_hz: 5000

# EXP1 BTN_ENC

output_pin: gpio.13

# FAN1

enable_pin: I2SO.16

disable_with_s0: false

s0_with_disable: false

tool_num: 0

speed_map: 0=0.000% 0=12.500% 1700=100.000%

# 135=0mA 270=5mA 400=10mA 700=16mA

user_outputs:

analog0_pin: NO_PIN

analog1_pin: NO_PIN

analog2_pin: NO_PIN

analog3_pin: NO_PIN

analog0_hz: 5000

analog1_hz: 5000

analog2_hz: 5000

analog3_hz: 5000

digital0_pin: NO_PIN

digital1_pin: NO_PIN

digital2_pin: NO_PIN

digital3_pin: NO_PIN

start:

must_home: false

The Laser portion, coolant, macros, etc can probably all be deleted, I just didn’t bother trying to cut that out yet.

As for gSender, apparently FluidNC does not send a $$ command upon connecting like plain GRBL does. In order for gSender to be able to work:

- Connect to the board with gSender.

- Access the FluidNC web portal.

- Reset the firmware through the web portal (under the middle GRBL panel, red square logo with a turn over arrow.).

- gSender should now work allowing you to jog. You still have to use the web portal to home each axis for some reason, but you can load gCode files through gSender to visualize and run.