Some little brackets for a toilet paper extra roll holder. Kept it simple. But worked great. I’m completely thrilled!

Heck yeah!!

You should be thrilled! Congratulations on getting up and running.

Let’s see more of your build.

It’s always a good day when another community member puts a machine online.

I love those “little” projects!

Not every CNC project has to be complex or enormous, if the CNC is the right tool for the job, just go for it.

To me, a CNC is a woodworking tool like any other, it’s great at precisely cutting complex/curved shapes such as small brackets

This could have been done on the bandsaw too, but once you have the CNC setup it’s pretty much easier to just design and run the file rather than design, print, stick paper to the wood, run it on the bandsaw, sand to the line, and do this twice…

Quick tip: a small roundover on the edges does a great job at giving a more “finished” look, and it also saves you from sanding the tabs away

Cool! Congrats!!

Sorry this took a while. I needed to get some stuff done before I was willing to take pictures.

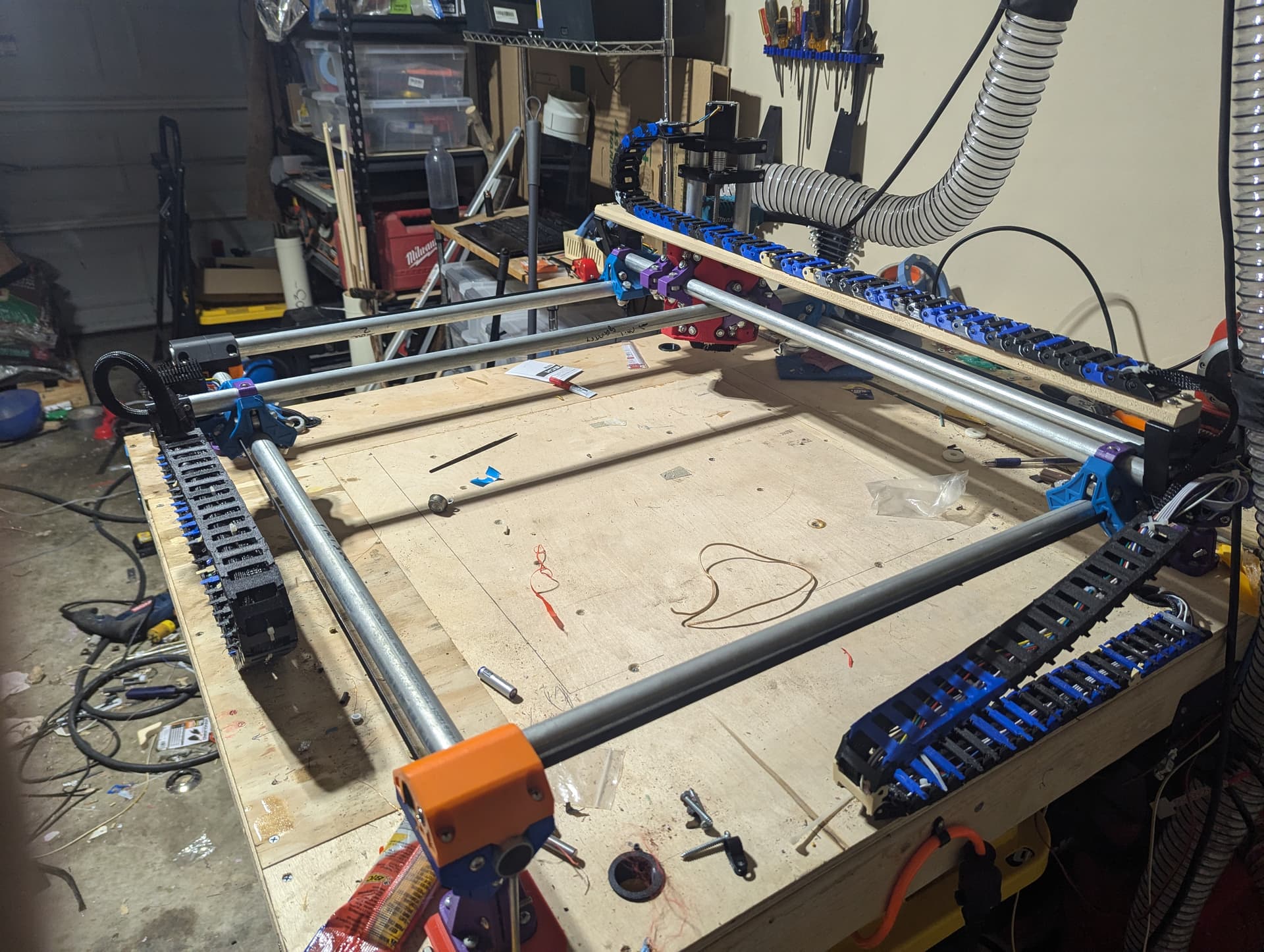

Here is the setup as it sits now.

Sharp rig!!

Thank you! Now if I can just figure out a workflow for relief carving I’ll be good to go. Estlcam just locks up when I feed it an STL.

Wow. How many polygons are in that STL?!

When I try to convert mesh to solid in Fusion it tells me it would be over 10,000 triangles. Im trying to use a lithopane of my son converted from a photograph.

Ah. Lithophanes are usually a huge amount of polygons.

Fusion has a button feature that seeks to adaptively reduce the number of polygons. It’s helpful.

Thank you, l will try that.

Looks great.

Many of us have stuff we’d like to clean up, fix, or finish- but you should feel welcome to share your pictures. Odds are many of us are in the same boat.

For every one person with the courage to post things, there are many,many more that think “Yep, that’s me.”

What can I say I’m used to Reddit, where if I’d left it how it was I would have gotten a bunch of comments about how unsafe my setup was (it wasn’t ideal certainly, I had cords running everywhere and ) but now I have better control panel that I don’t have to reach into the machine to turn my router on and off, my wiring is tucked up and it is the way under the table, and an E-stop and breaker on the router and computer in case things go sideways. I’m actually proud to present it in it’s current state. I’m really pleased with it.

The only thing you will ever get roasted for here is trying to remote monitor your CNC…anything else is not serious to us.

In Fusion if you right click on the mesh and click properties, you can expand that window and it will tell you how many triangles. The reason I ask is, Estlcam opened a 1.3mil triangle STL and generated carve paths for me. And that was on a Mac running Estlcam in a VM. Are lithopanes typically more than that? I haven’t ever messed with them.

I really don’t know. I’ve done manual machining and 3D printing. This is my first foray into the CNC world. When printing I just make sure they’re well supported. I made a simpler model directly in Fusion then exported it to stl and it loaded perfectly in estlcam. I think it’s the lithopane files giving it fits.