Thanks all for the help. I did a bunch of testing tonight and here are the results.

Summary

* changing the gcode to move the Z raise step up 1 line (before xy move) fixed it

* doing a very similar svg (My first draft) in ESTLCAM properly put a Z raise in the generated g-code BEFORE the first move.

* seems a lot of evidence to suggest a kiri:moto issue.

At least I have some idea what I can do now (change the g-code or use estlcam). I can reach out to the Kiri moto dev (again).

THE WEEDS

recreated again.

new "CNC printer (setup same as v1 docs)

lowered travel speed to 2100 (as stated in v1 setup docs)

everything to v1 specs this time.

updated repetier version v2.3.2

cuts the same with new file

Rambo 1.4 > v1 custom menu>reset all coordinates

both LCD and Repetier change to zeroes on all axis

script G92 X0 Y0 Z0,

still zeros

Repetier doesnt show the first travel either.

how does it know which to label as travel?

try again raising 20mm Z

left zero on top of workpiece

used repetier-host manual control to raise to 20mm above zero

cuts into air

try changing the g-code to move the raise Z up

Hmm will I also need a drop Z?

BEFORE

; --- tools ---

; tool=[object Object] flute=undefined len=undefined metric=undefined

G21 ; set units to MM (required)

G90 ; absolute position mode (required)

; starting trace op

M6 T2 ; change tool to 'end 1/8'

G0 X70.5704 Y41.8437 F2100

G0 Z2.0 F480

G1 X70.5744 Y41.8429 Z1.9980 F250

G1 X70.9180 Y41.8044 Z1.8251

G1 X71.1783 Y41.7897 Z1.6948

AFTER

; --- tools ---

; tool=[object Object] flute=undefined len=undefined metric=undefined

G21 ; set units to MM (required)

G90 ; absolute position mode (required)

; starting trace op

M6 T2 ; change tool to 'end 1/8'

G0 Z2.0 F480

G0 X70.5704 Y41.8437 F2100

G1 X70.5744 Y41.8429 Z1.9980 F250

G1 X70.9180 Y41.8044 Z1.8251

Setting up to run this I noted if Z is particularly high my dust shoe hits the bolts and might rack the Z. I can maybe sand this down but I think it is too high to be of consequence.

I also notice that when I try to do F0 X0 Y0 Z0 to return to the zero that the Z is up in the air now. Not sure why?? I will reset.

this time I ran the Script 1: g0 X0 Y0 Z0 instead of the LCD and confirmed the script worked to reset all to zero. (the bit was at the top of the workpiece in a new fresh position so I can evaluate cut).

load modified file, which I expect to cut 2mm (Clearance distance) in the air.

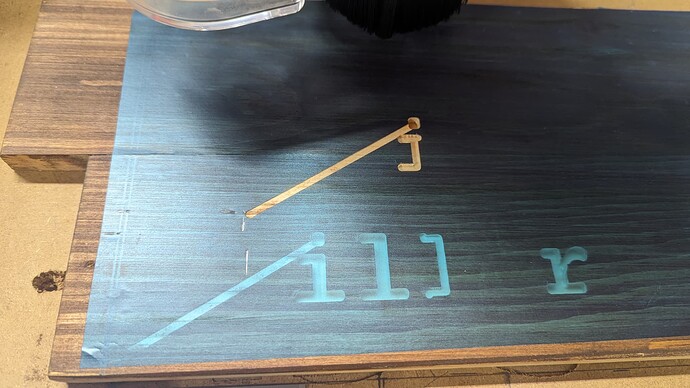

Interesting, it worked as desired not as expected. It raised then moved then dropped and cut. And the resulting depth of the lettring is the SAME as the previosu cut. So somehow the drop was accurate without change. I guess the G1 moves specify absolute positioning as per setup so it worked. Very cool. I still do not know why it is "out of order but hey.

I opened a slighlty different file I had as SVG (different font and not 3D) I pathed it up in ESTLCAM and saved the gcode.

The gcode

; set current location as Origin

G92 X0 Y0 Z0

G90

M03 S24000

G00 Z2.0000

;No. 1: Hole 22

G00 X15.3616 Y15.4841

G00 Z0.5000

G01 Z0.0000 F180 S24000

G01 Z-1.0000

G01 X327.9065 F900

G01 X328.8952 Y16.6766

okay when it ran it raised up automatically for travel. Notice the initial G00 Z2.0

so it looks like something in the Kiri:moto output is putting the Z raise in the wrong spot.

the_millers_file-002.gcode (113.2 KB)

The above g-code is the not raizing the Z before the move

TheMillers_as_paths_for_estlcam.gcode (151.0 KB)

This second gcode file is the once from estlcam which worked raising the Z before the move.