Without seeing how you setup your cut, it is hard to know what is causing your problem. There are a few things I see here for you to consider:

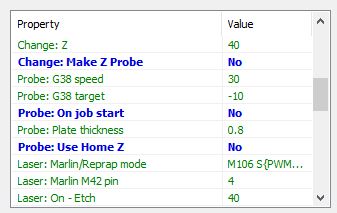

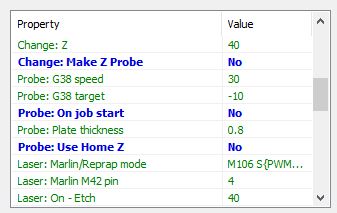

Z probing - Most of the time I see z probing done as a separate operation rather than part of a cutting file. Just to eliminate some complexity, I recommend turning off z probing and setting your z height by hand. Just put a piece of paper down and lower your router by twisting the lead screw by hand until the paper is just dragging on the paper. I turned off my auto probing and homing by changing the following parameters (in blue) in the post processor:

After you get a few successful cuts, you can turn Z probing back on or run it as a separate operation.

G92 Z0.8

I’m not sure how tall your touch plate is, but this line is assuming it is 0.8mm tall.

G1 X74.878 Y93.39 Z15 F1000

Recently Fusion 360 placed more limits on the Personal License user of their product. One change for CAM was the removal of rapid movements. In previous version of Fusion 360, the Z movement would have been a separate line of g-code. Now it is folded into the XY movement. But this is a problem for the MPCNC. The lead screw for Z cannot move as fast as the belt driven X & Y. In other words, 1000mm/min (F1000) is too fast for a Z movement.

The fix for this problem is to add a M203 - set maximum feedrate. This g-code takes parameters in mm/sec where most other places feedrate is set at mm/min. For now I suggest you keep your Z feedrate at or below 480mm/min (8mm/sec). So to get up and running, just add this to the top of your file g-code files:

M203 Z8

Note that the resident Marlin guru on this forum (Jeff) indicates that this value is one of the values saved when the M500 g-code is executed. While I’ve not tried it, you should be able to make this change stick even if the electronics are cycled by running this once:

M203 Z8

M500

As another way to automatically include this code, there is a property in the post processor that will allow you to automatically include other scripts in each g-code file output. And if you are using Repetier-Host, it too has a way to include start scripts.

Note that if you are moving your router electronically rather than just dragging the router by hand, you are missing g-code that establishes the router’s position at the start of the cut as the origin/home position for the cut.

I suspect your cutting issue is the feedrate problem I mentioned, but there are ways you could have setup the cut in fusion that would cause this kind of problem.