It can be argued of course that doing small pieces on the LR4 (42" x 72" capacity) doesn’t make too much sense.

However there is a ton that can be learned in preparation for doing a large piece.

For example, if the piece is going to take 12 hours, you are going to need to pause at some point, almost certainly. If you pause overnight, your motors are likely to dis-enable which will mean that the slightest touch of the gantry will shift your zero. Or if the z-axis is dis-enabled, the gantry may fall.

Or if you need to do a tool change, shifts can happen.

Anyway, all this stuff can be tested on a small piece without needing to use a large amount of material.

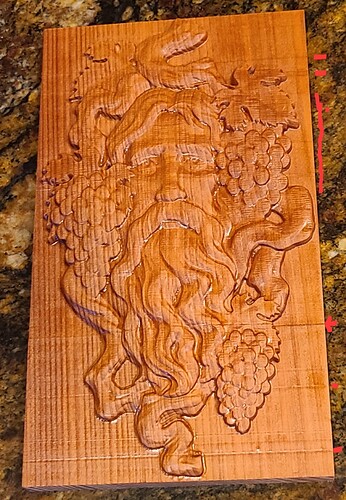

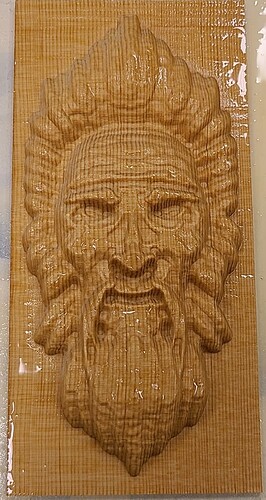

So, to that end, I tackled this guy:

(This piece is about 4.75" x 8". Wood is redwood. Maximum depth is 15 mm. Entire CAM done in EstlCAM)

As can easily be seen, there are some defects, nearly all of which are the result of a long pause (a few hours to overnight) and the resulting slight falling of the z-axis.

In addition, some detail was lost because of a slight “y shift” (~1mm?) due to an unlocked y-axis. And there are some tooling marks that also probably came from the y shift before the final finishing pass.

So, this little demo is offered as a learning exercise and to demonstrate that “it will cut” for any of you who may be “Forged in Fire” fans.