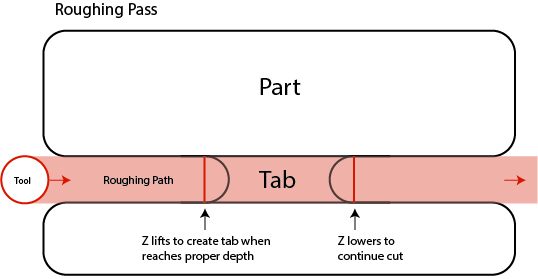

I have an issue with finishing passes not cutting as expected when encountering tabs on pine at any thickness. It is such a quick and subtle thing that I had to diagram it so that it would make sense.

When cutting a part with a finishing pass using the same tool the roughing pass cuts perfectly fine. However, when the router conducts the finishing operation with the same tool it does something very strange - at least to a CNC noob.

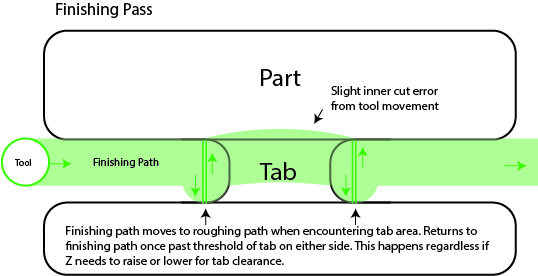

When the finishing pass encounters the tab area it quickly moves to the roughing path, immediately moves back to the finishing path, cuts the area above the tab, quickly move back to the roughing path, and then immediately moves to the finishing path and continue on. This happens regardless if the Z needs to raise to clear the tab.

This whole strange operation creates a small depression above the tab from the tool moving in an out so fast. It can be smoothed out by sanding but that kind of defeats the purpose of a finish cut for my application. If anyone has any insight on if this is normal or how to fix this it would be greatly appreciated. Thanks!