Version 2 of the test

I decided to take the time to test out a bunch of different filaments and compare them for rigidity. Thought I’d share the results in case anyone found them helpful.

Note that these results give a comparison of filaments within the context of the tests performed. It isn’t supposed to be the final word on what filament is the best for your machine, but it can maybe provide another data point to help you decide. Just keep in mind the following:

- These tests use a static load. Pieces may exhibit different behavior under a dynamic load

- While the tests do look at filament from different orientations, how that translates to the loads on the printed MPCNC parts is hard to fully determine

- People have printed MPCNC parts with a lot of different filaments, even some that are for sure more flexible than those listed…and most report they work fine for what they are doing

- The impact of filament rigidity on the overall machine rigidity is somewhat hard to determine, i.e. does a filament that is 30% less rigid reduce the machine rigidity by 30%…likely no

- All the tests were done with the same number of perimeters and infill for the orientation. An interesting test might be to take the most rigid, reduce the perimeters, and see how many perimeters it takes to match the rigidity with a less rigid filament. I don’t think it’s possible to make a PETG part match a PLA part, but you might get reasonably close

- Filament can vary a lot from company to company depending on their formulations. It can also vary by color to some degree. Just keep that in mind.

- Annealing was not tested as it’s not easy to do right and can really distort the pieces. It does help with most filaments though if you want to try it

I changed up the tests slightly for this Version 2 and added a few things. Here are the changes:

- Added “edge” orientation

- Changed flat orientation to 4 perimeters instead of 6 so all the walls are similar (see chart below)

- For flat and edge only went to 25# instead of 35#

- reprinted some samples with higher temps for better layer adhesion

- Added a few more filaments

- Based on the consistency of results from version 1, only printed 2 samples per orientation

Skip down if you don’t care about all the setup info and just want results. Look for the graph with the dark background and the comments after

The Setup

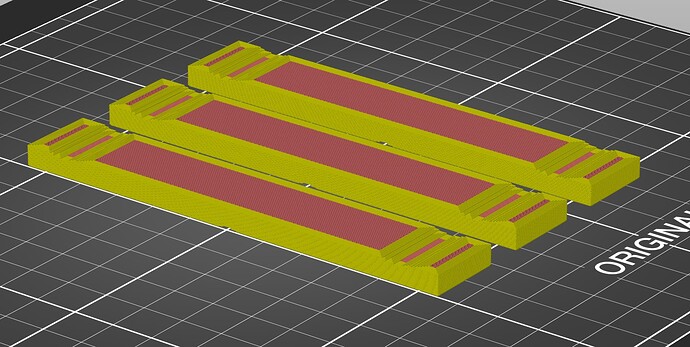

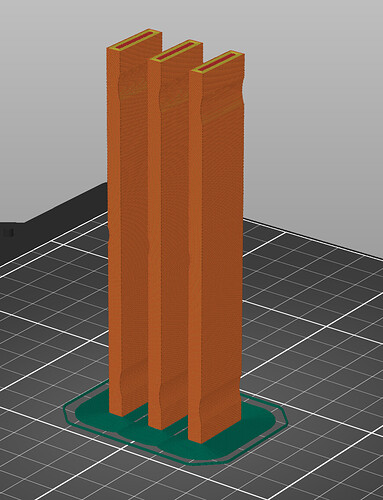

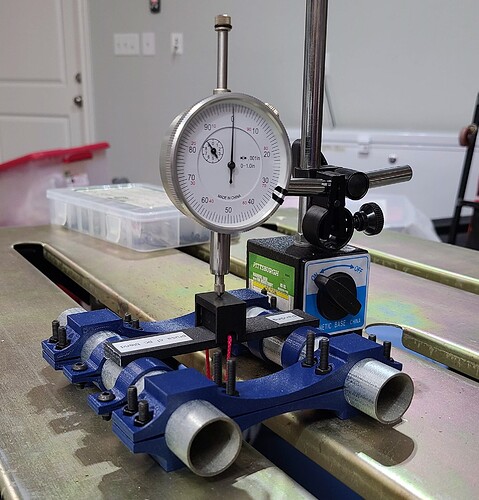

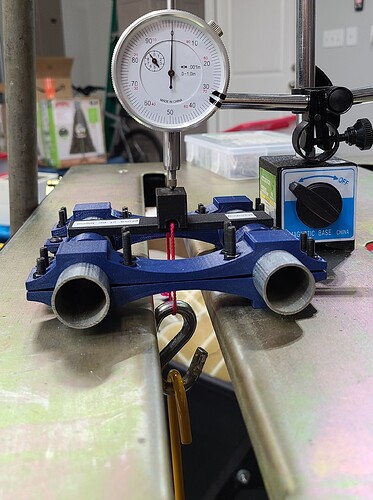

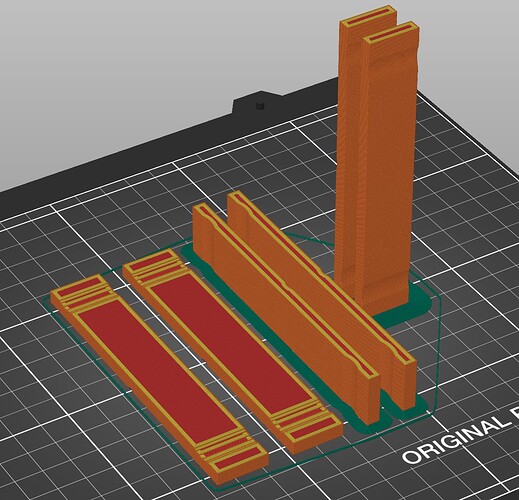

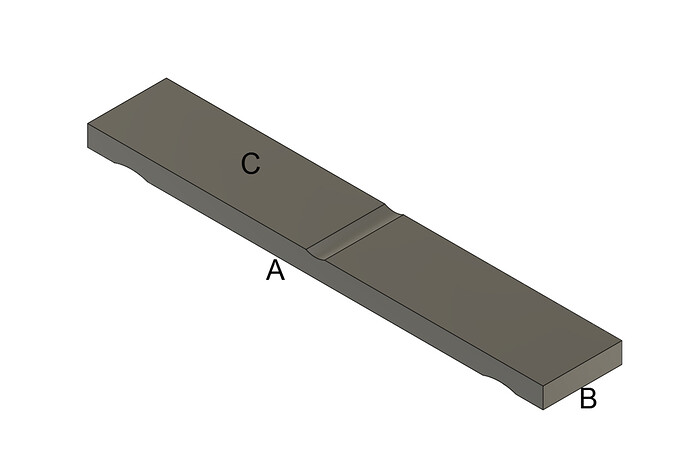

Samples were printed in three different orientations: horizontal flat, horizontal on edge, and vertical (standing). Two samples per orientation.

(Note: I reused the version 1 standing tests for most of the PLA where possible)

All filaments were dried in a food dehydrator, printed from a heated dry box, in a temp controlled enclosure (door open for PLA).

The Filaments Tested

I’ve given the MSRP cost for each but you can often find some of these on sale for a lot less. Because some spools are less than 1kg, I calc the cost per kg to make it easier to compare. Then how many spools you’ll need for 3kg and 4kg. I think you could print all the MPCNC with 3kg but that assumes no reprints and it’s tight.

| Manufacturer |

Type |

Color |

Category |

MSRP per spool |

Spool Size (g) |

Density g/cc |

Cost 1kg |

Spools for 3kg |

MSRP 3kg spools |

Spools for 4kg |

MSRP 4kg spools |

| Matterhackers |

Pro Series PLA (PLA+) |

Translucent Clear |

PLA |

$52.00 |

1000 |

1.24 |

$52.00 |

3 |

$156.00 |

4 |

$208.00 |

| Atomic |

PLA |

Silver Metallic |

PLA |

$29.99 |

1000 |

1.24 |

$29.99 |

3 |

$89.97 |

4 |

$119.96 |

| Hatchbox |

PLA |

Black |

PLA |

$24.99 |

1000 |

1.24 |

$24.99 |

3 |

$74.97 |

4 |

$99.96 |

| Hatchbox |

Performance PLA |

Blue |

PLA |

$28.99 |

1000 |

1.24 |

$28.99 |

3 |

$86.97 |

4 |

$115.96 |

| Sunlu |

PLA |

Grey |

PLA |

$21.99 |

1000 |

1.24 |

$21.99 |

3 |

$65.97 |

4 |

$87.96 |

| Printed Solid |

Jessie PLA |

Gun Metal Grey |

PLA |

$20.00 |

1000 |

1.24 |

$20.00 |

3 |

$60.00 |

4 |

$80.00 |

| Printed Solid |

Jessie PLA |

Red Ice |

PLA |

$20.00 |

1000 |

1.24 |

$20.00 |

3 |

$60.00 |

4 |

$80.00 |

| Overture |

Eco-PLA |

Black |

PLA |

$17.99 |

1000 |

|

$17.99 |

3 |

$53.97 |

4 |

$71.96 |

| Hatchbox |

Matte PLA |

Blue |

PLA |

$25.99 |

1000 |

|

$25.99 |

3 |

$77.97 |

4 |

$103.96 |

| Prusa |

Prusament PETG |

White |

PETG |

$29.99 |

1000 |

1.27 |

$29.99 |

3 |

$89.97 |

4 |

$119.96 |

| Hatchbox |

PETG |

Chocolate |

PETG |

$24.99 |

1000 |

1.27 |

$24.99 |

3 |

$74.97 |

4 |

$99.96 |

| Atomic |

CF Extreme Black PETG |

Black |

CF PETG |

$49.99 |

1000 |

1.34 |

$49.99 |

3 |

$149.97 |

4 |

$199.96 |

| 3DXtech |

CarbonX CF PETG |

Black |

CF PETG |

$48.00 |

750 |

1.34 |

$64.00 |

4 |

$192.00 |

6 |

$288.00 |

| Prusa |

CF PC Blend |

Black |

CF PC Blend |

$59.99 |

800 |

1.16 |

$74.99 |

4 |

$239.96 |

5 |

$299.95 |

Print settings and temps for each filament and orientation:

|

Flat |

Edge |

Standing |

| Nozzle |

0.4 |

0.4 |

0.4 |

| Layer height |

0.3 |

0.3 |

0.3 |

| Perimeters |

4 |

4 |

4 |

| Top/bottom layers |

6 |

6 |

6 |

| Infill |

50% |

50% |

50% |

| Fill pattern |

Grid |

Grid |

Grid |

| Extrusion width |

0.5 |

0.5 |

0.5 |

Monotonic top and bottom layers.

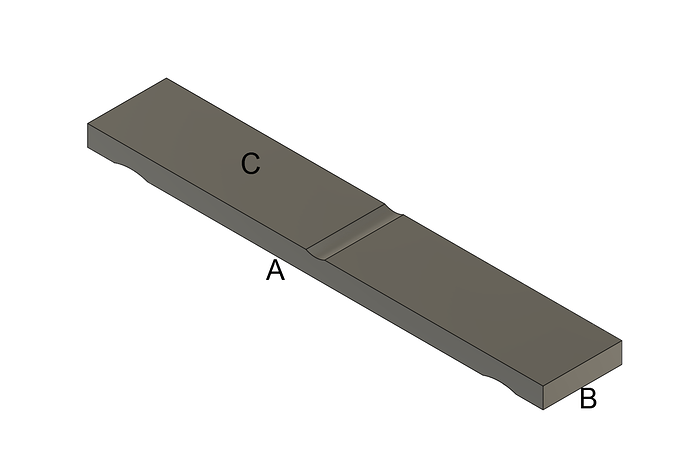

This gives wall thickness of:

|

A |

B |

C |

| Flat |

1.77 |

1.77 |

1.8 |

| Standing |

1.77 |

1.8 |

1.77 |

| Edge |

1.8 |

1.77 |

1.77 |

| Manufacturer |

Type |

Color |

Category |

temp flat |

temp edge |

temp standing |

| Matterhackers |

Pro Series PLA (PLA+) |

Translucent Clear |

PLA |

215 |

215 |

215 |

| Atomic |

PLA |

Silver Metallic |

PLA |

215 |

215 |

215 |

| Hatchbox |

PLA |

Black |

PLA |

215 |

215 |

215 |

| Hatchbox |

Performance PLA |

Blue |

PLA |

215 |

215 |

215 |

| Sunlu |

PLA |

Grey |

PLA |

215 |

215 |

215 |

| Printed Solid |

Jessie PLA |

Gun Metal Grey |

PLA |

215 |

215 |

215 |

| Printed Solid |

Jessie PLA |

Red Ice |

PLA |

215 |

215 |

215 |

| Overture |

Eco-PLA |

Black |

PLA |

215 |

215 |

215 |

| Hatchbox |

Matte PLA |

Blue |

PLA |

225 |

225 |

225 |

| Prusa |

Prusament PETG |

White |

PETG |

260 |

260 |

260 |

| Hatchbox |

PETG |

Chocolate |

PETG |

260 |

260 |

260 |

| Atomic |

CF Extreme Black PETG |

Black |

CF PETG |

265 |

265 |

265 |

| 3DXtech |

CarbonX CF PETG (265deg) |

Black |

CF PETG |

265 |

265 |

265 |

| Prusa |

CF PC Blend |

Black |

CF PC |

285 |

285 |

285 |

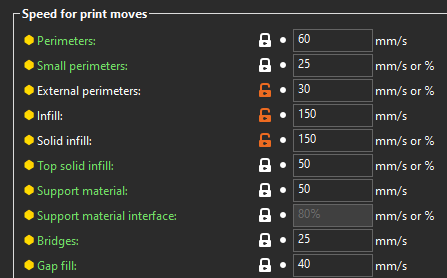

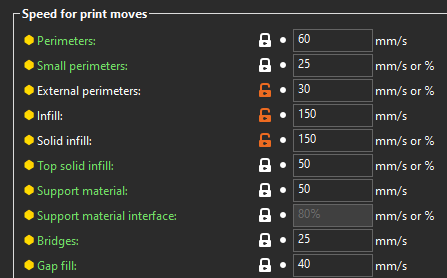

Speeds used:

The Results

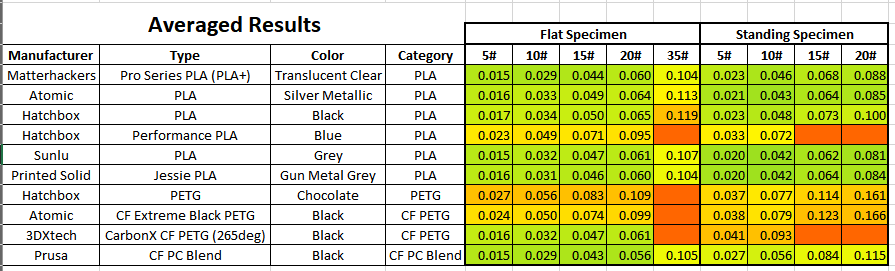

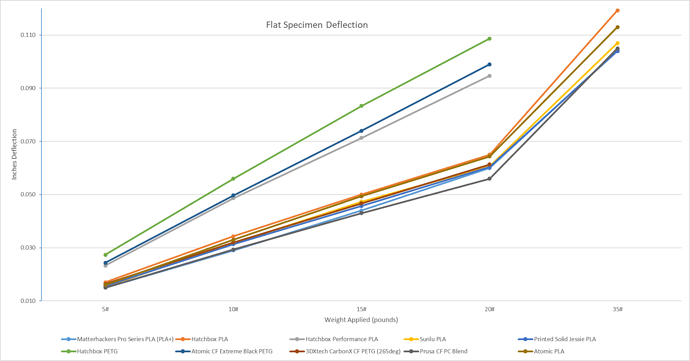

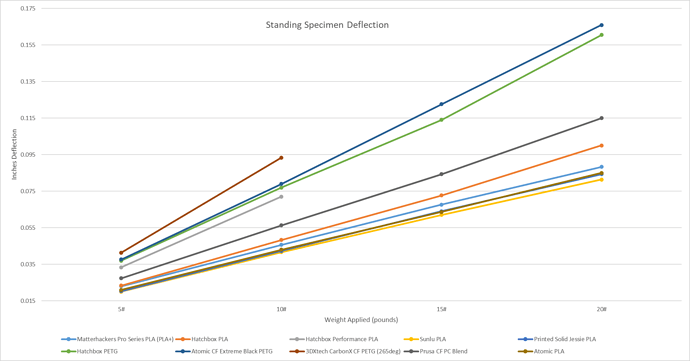

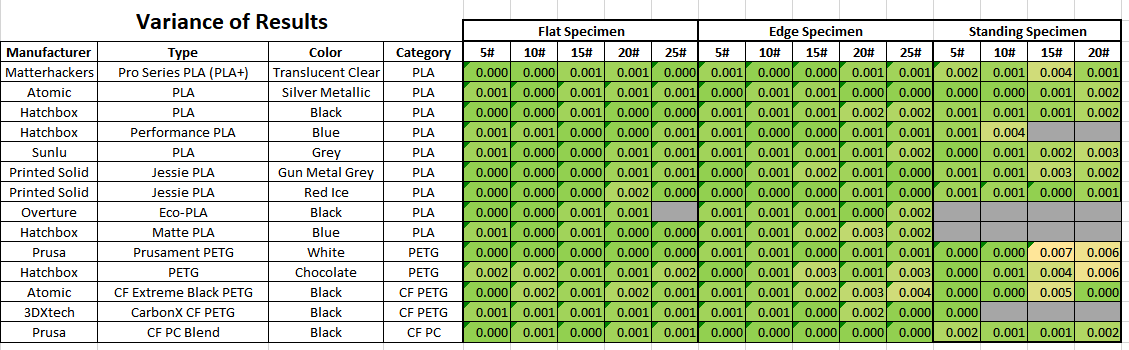

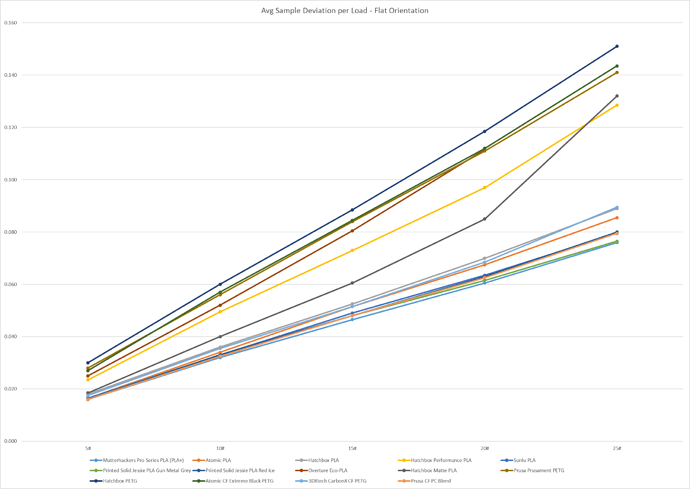

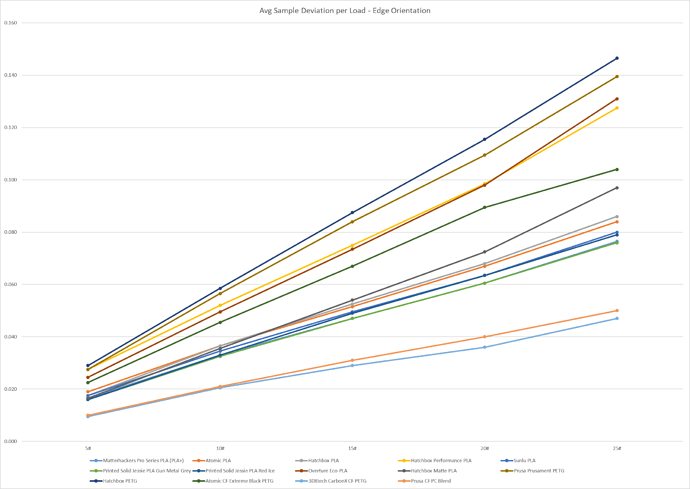

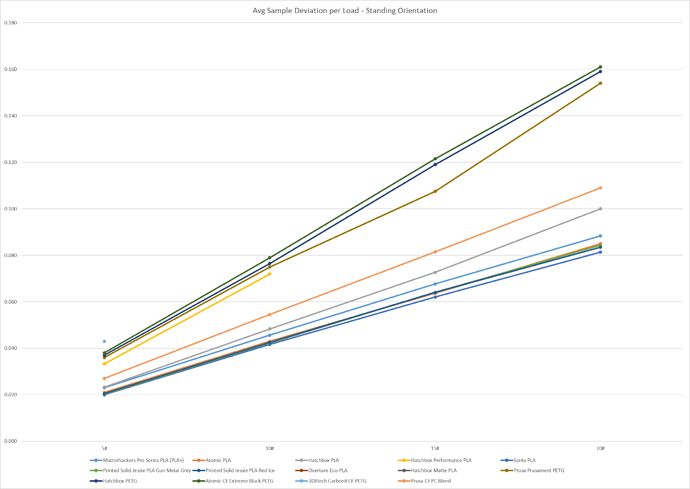

For each filament at each orientation, multiple samples were tested and averaged together. The variance between those tests was within reason, only getting slightly higher for the softer filaments at higher loads.

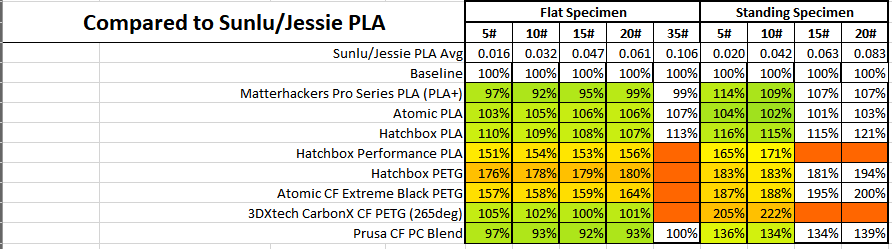

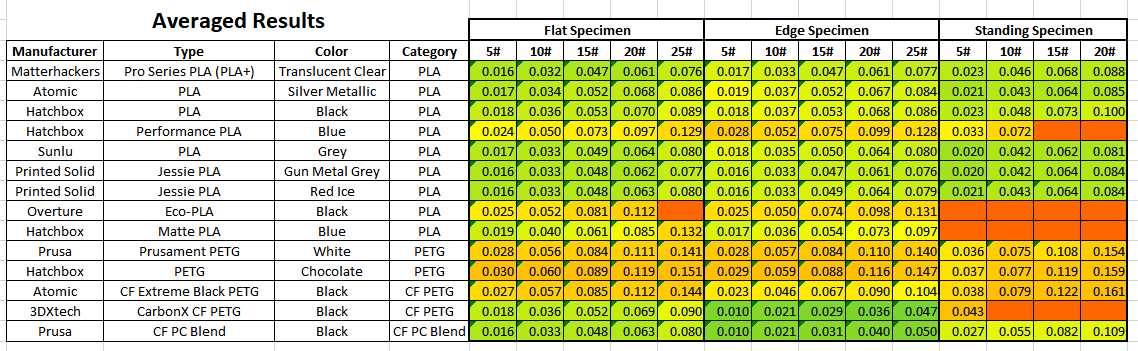

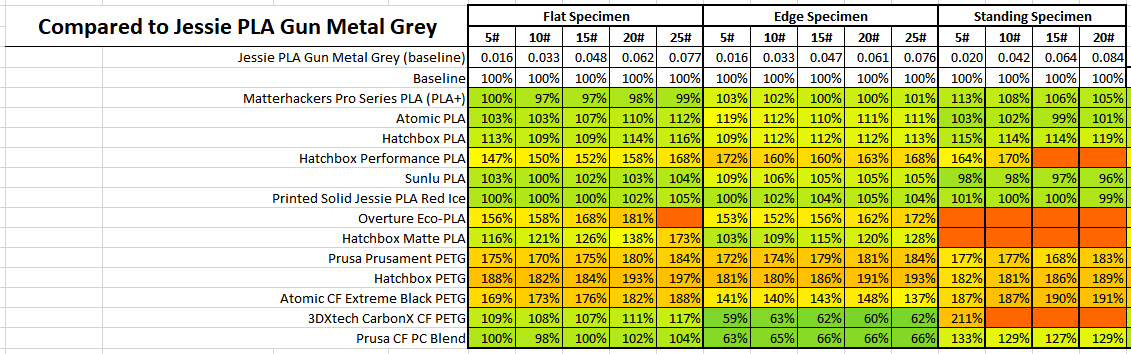

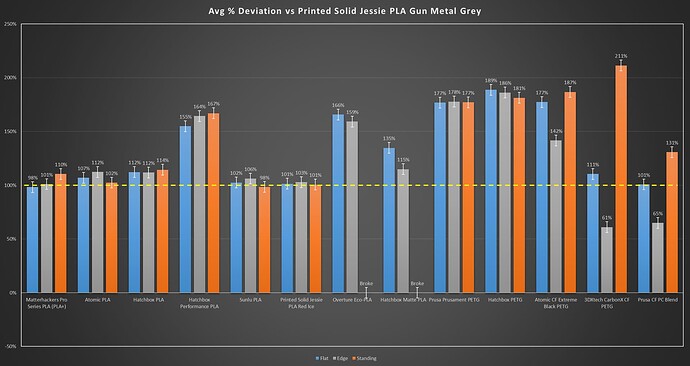

This chart and the following graphs show the amount of bend for each filament, averaged across the samples for each orientation. Note we are not really interested in the actual amount, but the comparison between filaments.

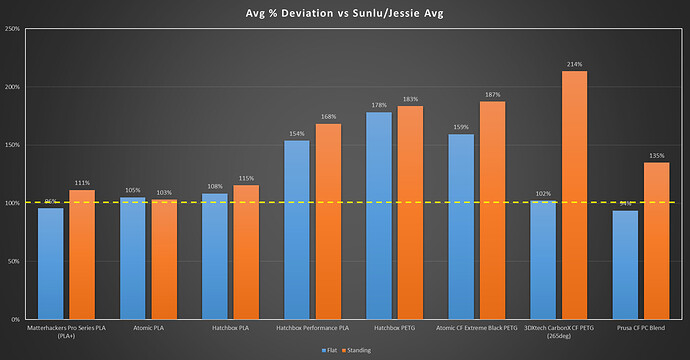

I decided to choose one filament to serve as the baseline to compare all the others to. The Printed Solid Jessie PLA in Gun Metal Grey was very stable in testing and serves as a good representation of a non-modified PLA. The following chart is the % deviation of the other filaments to this baseline.

The % deviation was reasonably consistent across the samples so the following averages those to a singe % and graphs them. I think this gives a good overall look at the rigidity for each filament and allows the best comparisons.

Note: Higher % over baseline = less rigid. Lower % under baseline = more rigid

Thoughts and Conclusions

PLA

There is a reason PLA is the suggested filament to print MPCNC components: it’s amazingly strong, it’s cheap, and it’s easy to print with! It’s main weakness is temperature resistance and sometimes it’s a bit brittle which can cause it to crack. Also note that there are many variations of PLA (like most filament types). Some of those variations are more obvious from the name than others.

-

Printed Solid Jessie PLA, Sunlu PLA, Atomic PLA, Matterhackers Pro Series PLA - These performed very well and very similarly. I was surprised the Matterhackers PLA did so well as it’s marked PLA+ on the roll and that usually means it’s not as rigid, but it did fantastic. One note about the MH though, it was a translucent clear filament. I’d have to test a colored filament like black to make sure the results can be applied to these across the board. Also of note, the PS Jessie Red Ice did slightly worse than the gun metal grey. Just enough to note, not enough to prevent using. It just highlights that even the additives to make a color can cause variations in rigidity.

-

Hatchbox PLA - This is a great PLA but it is slightly less stiff than the ones above likely just due to the formulation HB uses. I still think it’s viable, but would argue there is no point going out of your way to get it if you are buying new. If you have it already, I think it’s fine to use.

-

Hatchbox Performance PLA - This is a good example of a modified PLA. Often companies label this as Tough PLA or similar and it’s simply more flexible, designed to take impacts better. I would not recommend this for MPCNC parts as you get all the negatives of PETG without any of the benefits.

-

Overture Eco-PLA - Note this is not the normal Overture PLA. This is a recycled PLA and did not perform well at all. It had terrible layer adhesion and no standing samples could hold even 5#. It was nice to look at though, but just not strong. I would avoid for the MPCNC. Regular Overture PLA is probably fine but I have not tested.

-

Hatchbox Matte PLA - Similar issues to the Eco-PLA. It’s just not strong enough. It’s beautiful though. Most Matte PLAs are modified with something and are much weaker than regular pure PLA. In general I’d recommend avoiding matte filaments for the MPCNC parts.

PETG

PETG is the go to second option for a lot of people as they are trying combat temperature issues found in the location of the MPCNC, or they have broken PLA parts and want something more resilient. PETG handles both issues very well, and there are several machines running PETG successfully. However, it comes at a cost. PETG feels almost rubbery compared to PLA and flexes a lot more. I’m not sure you could give it enough perimeters to really offset this characteristic of the base material, but perhaps someone can test that.

-

Prusa Prusament PETG - Note this is a white PETG which sometimes acts a little different than other colors. It resulted measurably better than the Hatchbox. However, PETG is still 80+% more flexible than PLA. I can’t overstate how it is just not on the same planet as PLA for stiffness.

-

Hatchbox PETG - Slightly more flexible than the Prusa. Very flexible relative to PLA.

Carbon Fiber Filaments

I’ll just discuss these on their own as they really do act a lot different than the pure filaments.

The addition of carbon fiber to the base resin really does stiffen the sample…well sort of. These tests are measuring the flexural strength of the material. That means it’s bending a beam-like structure causing compression on the top side and tension on the bottom side. The carbon fibers travel along, and are oriented with, the direction of the layer path. As long as the forces are traveling along those paths, carbon fiber can help out. Same as in all composites. Since no strands of carbon fiber orient between the layers (the Z direction), objects like our standing samples do not benefit at all from CF, and may even be weaker due to the often weaker layer adhesion CF filament seems to produce. The edge samples have the most laters running perpendicular to the force, so they do the best. With CF filament, more perimeters make an even bigger impact than they do in just pure filament.

-

Atomic CF PETG - I’ve use this stuff a long time and I love printing with it. It’s marginally stiffer than regular PETG, but not much. Compared to most CF filament which prints in a matte finish, it maintains more of the PETG shininess. I would say it’s overall better than pure PETG for MPCNC parts, but not much.

-

3DXTech CarbonX CF PETG - So this stuff is interesting. It’s almost as stiff as PLA in the flat samples, and way stiffer in the edge samples (where the CF can help more). However, it’s about the same or worse as pure PETG in the standing samples. In fact, layer adhesion is so bad, and it flexes so much in this orientation, I could only get 5# on the sample before it broke.This goes back to the CF not being able to help at all in the standing samples. So, the effect of orientation of the layers relative to the force is really amplified here. I am really impressed with this filament, and other than the cost, it’s probably what I would use if I had to use PETG for really strong parts, having taken the layer orientation and forces into account of course. Is it ideal for the MPCNC? Well I don’t know. Some parts are probably going to have most of the forces going in the right direction, and some may not. So it’s probably ideal for some of the MPCNC, not ideal for some, and good enough for others.

-

Prusa CF Polycarbonate - I’ve printed a few rolls of this stuff over time and it’s pretty amazing. PC has ridiculous strength in tension and the addition of the CF makes it relatively easy to print. It’s as good as PLA flat, much stronger on edge, and not too bad standing. It has the best temp resistance of all these as well. Seems like the perfect material except: it’s expensive, requires a full metal hot end that can print 285c-295c, a bed that can reach 110c, it doesn’t bridge as well (but may can be tuned to acceptable levels), and I’ve seen a slight Z shrinkage on some parts (but I need to do more testing to validate and quantify). Should you use it? Well if you aren’t a 3D printing newbie, have extra money, are fine if some of the bridging isn’t perfect and you have to post process the parts more, want something that can handle any temp any garage ever could get to on planet earth, and want a rigid machine too? Well then yes, it’s a great choice.

I hope everyone finds this helpful. Testing filaments can go on forever and I’ve used about all the spare time I could muster on this. I’ll point you to Youtubers CNC Kitchen, My Tech Fun, and Thomas Sanladerer for more info on various filaments. One interesting test is for creep (how much a filament deflects over time with a load applied). My Tech Fun for sure tests that in an interesting way. These Youtubers also do tests on strength vs infill, strength vs perimeters, strength vs temperature, and a lot more.

Merry Christmas 2022 and Happy New Year 2023!

Link to spreadsheet for Version2: Filament Shootout V2 - Google Sheets