I’m suprised that you didn’t like the Fillamentum. I thought that was the generic filament that’s shipped with the Prusa printers? I think I read somewhere that Josef Prusa’s favourite filament, and I’ve thought that it’s considered as Prusaments cousin…?

Since I switched from a cheap bowden extruder to a titan aero direct extruder it doesn’t seem to matter what I throw at it… some might be a little prettier but most of my prints tend to be functional stuff rather than for looks. I typically buy the cheapest rolls I can find on amazon and haven’t had too many problems. Strength is linear to infill so 50% infill will be twice as strong as 25%.

Perimeters are also critical for strength. Interesting to hear about the extruder’s role in getting good prints!

I imagine that a better extruder (the gears that drive the filament) combined with a better Hot end (The nozzle and cooling parts) would be helpful in preventing jams and keeping a smooth consistent extrusion. Many cheap bowden setups suffer from under extrusion. Meaning the motor will turn the correct amount to drive 100 mm of filament but there is enough friction, resistance or slippage that it only pushes something like 90 mm. Under extrusion can cause some randomness because it may push 90 or 100 or 80 or jam completely. So a good quality extruder/hotend is helpful to get consistent extrusion amounts.

However I can tell you for certain that filament tolerance to thickness makes a difference. If the Filament is supposed to be 1.75 mm thick but it is actually closer to 1.70 on average with some pieces of it being 1.77 mm thick. Then you will get some funky patterns in your prints. If you were printing a large flat surface then you would see the lines that are printed don’t quite touch. Leaving behind thin holes between the lines. Then every once in a while you will get ugly bumps that stick up higher than the rest. Those are caused by the thick parts of the filament. If you are making structural pieces like tailslide said then it doesn’t matter much if at all. But pretty pieces can be ruined by bad filament tolerances.

This is what I blame for most of my problems.

I usually blame the fact that I don’t make the time (and don’t have the patience) to properly calibrate and really dial in my printer. It doesn’t help that the printer is in the basement, and all the computers are on the main floor. Sneakernets suck.

If it wouldn’t kill my real work productivity, I’d bring my printer up into the office.

I get some parts that are great…

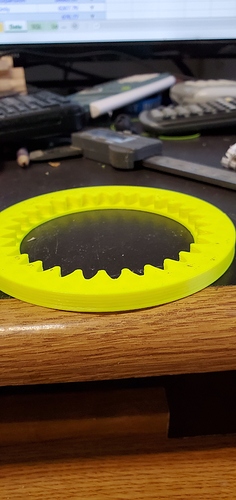

And then some garbage like this

Of course, I’m not making pretty things, so…

One of the key things to look for (in PLA) is how hydroscopic it is and what added fillers it has. This will impact print quality and brittleness. You can generally tell these by the temperature range that it wants to print at. The lower the temperature, the more wax and other fillers (that have a lower melting point) are mixed in with the filament (generally for color and texture). The higher the temperature, the more “pure” the PLA is. Don’t take this as an exact science (and I am far from an expert on the subject), but its a pretty good rule of thumb.

It’s quite common sense actually. The lower the temp, the weaker the bonds. It’s similar for most materials that are shaped/treated under temperature.

I’ve placed my order. I’m a little embarassed of my color choice, it’s a quite dandy. But the MPCN deserves to look good, so why not? Fillamentum vertigo gray and vertigo starlight…

Not sure how much you ordered, but I know I used over 2 kg for Burly and that doesn’t count failed prints, so you might want to make sure you have a bit of a buffer. In preparation for the new Primo print, I got 4 kg (2 kg of each color) to make sure I have enough of the color I want.

2.5kg. Ryan says he’s aiming to get weight below 2kg, let’s hope so!

Almost forgot… filaments.ca has a product called econofil that is $16/Kg CDN. You need to either print or buy your own reusable spool but hey… no more throwing spools in the garbage. The only downside is they have a pretty large minimum order for free shipping but they do have free shipping to both US and Canada. Looks like they are currently sold out.

I like the idea of a master spool, but the idea didn’t really take off. Very few vendors support it. It also starts to become expensive and time consuming if you have 20-30 rolls of filament “active” and even worse most master spool rolls are not very tight winds and can cause issues printing.

The empty spools are about $7 so even if you buy an empty spool with every roll it’s still competitive.

Mine’s still sitting on the shelf though hopefully I don’t have issues when the time comes to use it. There are some good reviews so at least some people got it working.

Inland (via Microcenter) also has spoolless which I use some, but only a few colors are available. It’s ok. A bit of saving but not a lot, and more hassle but not too bad. In the end it’s a wash.

why the aversion to a more varied palette?

I don’t mean to be “snarky” but the thread title simply asks what is my favorite PLA and I stated my preferences. I could say… it’s 'cause I’m a stuck-in-the-mud, a creature of habit, am happy with what works for me, etc? And while those things are true, I don’t see it as an “aversion”. I simply find it far more enjoyable spending my time building stuff than screwing around with my pretty well dialed-in printer and having to deal with the possible clogs/jams/problems caused by filaments I really don’t want or need.

I would add that in my experience it is better to work with what your are familiar with. I would guess I have used well over 100 spools of filament in the last few years. I have tested a couple dozen filament brands and types. Hundreds of my failed or ugly prints came from experimenting with bargain spools. I have had some PLA spools that refuse to adhere to the bed no matter what I try. Most of those have been thrown away before they are half used. I have had spools get extremely brittle very quickly! Some I have been able to limp along with but others have been trashed. I have even had one spool of PLA that must have absorbed a LOT of water from the air (like Nylon does). Because it would boil, bubble and pop as it was extruded. And I love in Colorado. It’s not very humid here unless it rains.

Some experiments have been really cool. Like the PLA with Wood dust in it. Smells like cedar when it prints. It can be sanded and even stained. Cool stuff. But long story short I have wasted too much of my time and company money on experimenting with different brands of filament. So when I find a brand that I can trust I will stick with it. For PLA the only time I try new brands now is when I need a color that is impossible to find in my list of trusted brands.

for me i use a bunch of brands, really i buy what is cheap and has good reviews on Amazon. my MPCNC parts are getting printed out of HZST3D brand filament. i find that most filament works well enough without clogging or having to play with temps a bunch but i’m also not that fussy (i think i only ever printed one temp tower in my life) but like @dkj4linux said, i was asked for favorites.