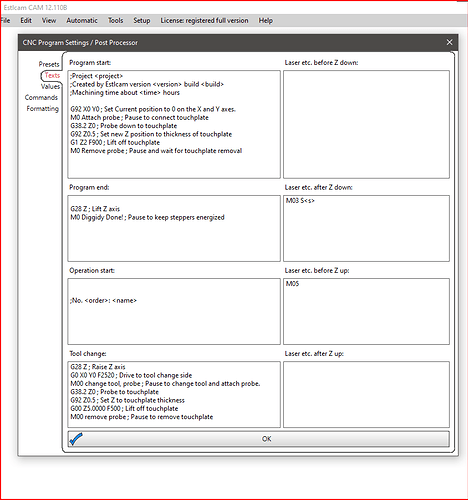

if you have a look at the top pics you will see codings r same but v12 says invalid

could do but thats just pain in the ass

Again, for the 3rd time, the CNC controller area is irrelevant for your use case.

It is not connected to your board.

It doesn’t know what your board understands.

Don’t use it.

What matters is in the file.

If you don’t want to attach them and don’t want to look there to see the differences, I don’t know how else to help you.

I hope you get it figured out

It does not matter what EstlCAM is telling you because you are NOT using EstlCAM as the controller!!!

Ryan tests everything he sends out.

Also, you can bundle the quotes and don’t have to make three posts.

Can you zip and upload your file for us to look at please. We can tell you right away if you got your starting gcode correct.

Hello,

I think there are a few things mixed up:

- You’re using Marlin to control your CNC - not Estlcams integrated controller.

- Estlcam and Marlin are both CNC controllers but other than that have little in common.

- So codes that are invalid for Estlcam can be valid vor Marlin and vice versa.

- So while Estlcam can create CNC programs for both Marlin and itself it can only validate the code for itself but not for other control systems. You need to check the programs for Marlin with Marlin itself.

I have no experience with Marlin and if it can report what exactly is wrong or missing.

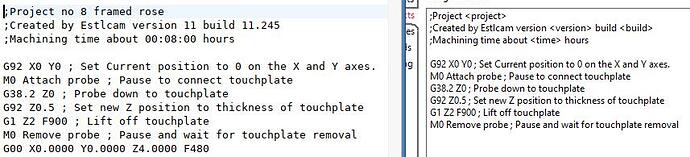

But if you have a working CNC program created by V11 and one that is not working created by V12 the most simple way to find the source of the issue is to compare those 2 files with a text editor and see what the differences are.

Christian

framed rose e12 acm.gcode (151.7 KB)

This is in the top of your V12 file

;Project framed rose

;Created by Estlcam version 12 build 12.110

;Machining time about 00:39:13 hours

M0 Attach probe ; Pause to connect touchplate

G38.2 Z0 ; Probe down to touchplate

G92 Z0.5 ; Set new Z position to thickness of touchplate

G1 Z2 F900 ; Lift off touchplate

M0 Remove probe ; Pause and wait for touchplate removal

This matches what is in your picture above.

I assume this matches your V11 file as well, but it was not attached to verify.

This means, V12 is doing what it is supposed to.

You need to approach troubleshooting this differently.

If you take the the V11 file and V12 file and run them back to back, I would expect the start codes to work identically

tried that ran the v11 file sweet as. put in v 12 and it wont stop at probe just keeps screwing down on the Z axis have than cut 3 different projects using v 11all probed sweet as . V 12 just won’t probe any file

Then what is the difference between the 2 files?

you didn’t post the v11 file for comparison.

They are just text files. The estlcam version number doesn’t matter if the text inside is the same

Is the problem happening during the initial probing or during the later tool change?

This is the tool change gcode from the file:

M0G28 Z ; Raise Z axis

G0 X0 Y0 F2520 ; Drive to tool change side

M00 change tool, probe ; Pause to change tool and attach probe.

G38.2 Z0 ; Probe to touchplate

G92 Z0.5 ; Set Z to touchplate thickness

G00 Z5.0000 F500 ; Lift off touchplate

M00 remove probe ; Pause to remove touchplate

I don’t know the Marlin-specifics of gcode but that “M0G28 Z” seems odd to me.

Yeah that M0 shouldn’t be there. Should just be G28 Z ; Raise Z axis

Here is what the docs show for marlin tool change for a LR3/4

M107 ; Turn fan 1 off IOT relay

G28 Z ; Raise Z axis

G0 X0 Y0 F2520 ; Drive to tool change side

M00 change tool, probe ; Pause to change tool and attach probe.

G38.2 Z0 ; Probe to touchplate

G92 Z0.5 ; Set Z to touchplate thickness

G00 Z5.0000 F500 ; Lift off touchplate

M00 remove probe ; Pause to remove touchplate

M106 ; Turn fan 1 on IoT relay

Looks like he is missing the G92 X0 Y0 but that shouldn’t have any effect on the probing

Here is what’s in the docs for Marlin start gcode for LR3/4

G92 X0 Y0 ; Set Current position to 0 on the X and Y axes.

M0 Attach probe ; Pause to connect touchplate

G38.2 Z0 ; Probe down to touchplate

G92 Z0.5 ; Set new Z position to thickness of touchplate

G1 Z2 F900 ; Lift off touchplate

M0 Remove probe ; Pause and wait for touchplate removal

M106 ; This will turn on an IOT relay to start a router or vacuum

No need to have the M106 if he isn’t using it. Not sure why he took out the G92 but as long as he is zeroing it some other way it should be fine. Much easier when its just all there in the start Gcode to me.

no 8 framed rose.gcode (63.8 KB)

on initial probing

mo g28 hmmm

if you look at top photos showing text settings for v11 and 12

theres no mog28 in text . i copied and pasted it from the milling page.

so where or how would the m0g28 end up in the final code ???

again hmmmm

the G92 is in the text in my settings

as you can see in images

but missing in the file ?

got me stumped

yip marlin highlighted no postprocessors

ive opened v 11 and 12 side by side triple checked every setting should all text boxs for laser under texts be empty in 11 defult is they are empty 12 they have text

Laser Texts entries are only used when the Laser tool is being used. All Text entries will be included in the G-code as written (v11 and 12). If you need something to preview and step through G-code give https://ncviewer.com/ a try.

No it’s not. The only difference is what appears to be a pointless/invalid G00 line that had to have been in Texts when the G-code was generated.

hey dave

, , a previous comment said the g92 is missing from the file , ur saying its not missing from the file ?

out of all the responses still no answers as to why v11 works fine but v 12 wont