It took quite a few passes to cut through the “four quarters” thick hardwood, but it did it. Each pass was 80% power, speed of 10 mm/sec. I don’t own a scroll saw, and my blades on my bandsaw are too wide for curves this tight. Made as a birthday gift for my adult daughter.

Looks very cute. It’s also always nice to meet other Borderlands players. ![]()

Thanks! Although I don’t know what Borderlands is. This was something my daughter requested. Is it from a game?

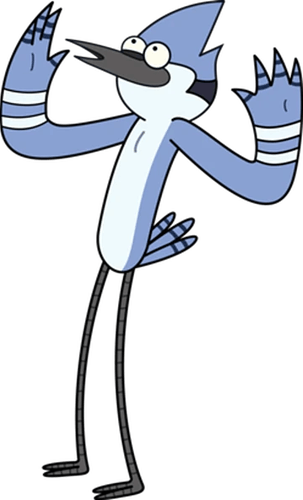

Mordecai is one of the character’s names, was just poking fun, knowing you (and probably your daughter) it is a reference to the bible, I guess and not to Borderlands. ![]()

Ah. It’s based on the Bible. Thanks for explaining the joke!

![]() I have been seeing these advertised non-stop for like a week now. Did you design or buy the files?

I have been seeing these advertised non-stop for like a week now. Did you design or buy the files?

Love how yours turned out

I drew my cut files myself from scratch, but clearly they are inspired by / based on existing products that are out there.

Two things I did not like about the existing products (some of the reasons I made instead of buying). They are smaller than mine (smaller than I wanted) and they were not “continuous grain” — they were not cut with all pieces in place, being cut “in situ” from a single board. Mine is.

How many is ‘quite a few’?

Because 4/4 maple is some tough stuff to cut with a laser.

Seeing this just further reinforces my desire to get a 100w CO2, especially if I’m thinking of doing 1/2” maple at a production speed.

Beautiful work

I started off trying to count how many passes I had to do, but it was late and I was tired and don’t actually know how many. You are right that Maple hardwood is harder to cut, and 1 inch thick even more so. I have to estimate how many passes… so this could be off. I am think maybe it was 10 or 12. It could have been more. I started pausing between passes to open the lid and hold down the board while trying to jiggle the smallest elephant to see if it felt loose enough!

PS: I would lower the laser every couple passes or so until I finally had the tip of the laser barrel almost touch the top of the wood. This was to push the focal point deeper into the cut.

Why did you choose laser over your CNC router?

From earlier post:

The “puzzle” type “slide in” fit means narrow kerf width is needed, I don’t own any bits that narrow much less than could cut through 1" thick hardwood while being that narrow.

Thanks, it would help if I read haha

closing old topic to help fight spambots