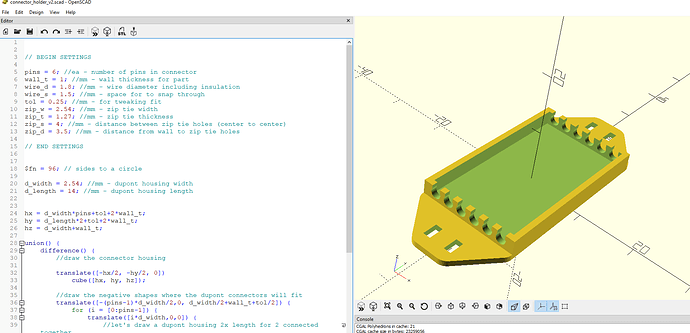

How about some zip ties for added security and strain relief?

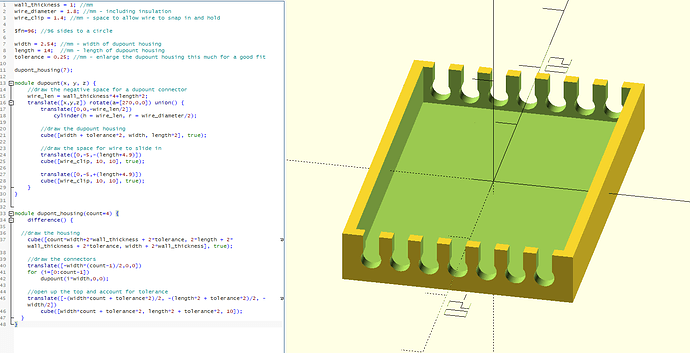

// BEGIN SETTINGS

pins = 6; //ea - number of pins in connector

wall_t = 1; //mm - wall thickness for part

wire_d = 1.8; //mm - wire diameter including insulation

wire_s = 1.5; //mm - space for to snap through

tol = 0.25; //mm - for tweaking fit

zip_w = 2.54; //mm - zip tie width

zip_t = 1.27; //mm - zip tie thickness

zip_s = 4; //mm - distance between zip tie holes (center to center)

zip_d = 3.5; //mm - distance from wall to zip tie holes

// END SETTINGS

$fn = 96; // sides to a circle

d_width = 2.54; //mm - dupont housing width

d_length = 14; //mm - dupont housing length

hx = d_width*pins+tol+2*wall_t;

hy = d_length*2+tol+2*wall_t;

hz = d_width+wall_t;

union() {

difference() {

//draw the connector housing

translate([-hx/2, -hy/2, 0])

cube([hx, hy, hz]);

//draw the negative shapes where the dupont connectors will fit

translate([-(pins-1)*d_width/2,0, d_width/2+wall_t+tol/2]) {

for (i = [0:pins-1]) {

translate([i*d_width,0,0]) {

//let's draw a dupont housing 2x length for 2 connected together

dx = d_width+tol;

dy = d_length*2 + tol;

dz = dx;

translate([0,0,dz/2]) cube([dx, dy, dz*2], true);

//draw the wire

rotate([90,0,0]) cylinder(h=dy+4*wall_t, r=wire_d/2, center= true);

//draw the wire slip

translate([0,0,0.75*dz]) cube([wire_s, dy+4*wall_t, dz*1.5], true);

}

}

}

}

//draw something to zip tie the wires to

zy = hy/2 + zip_w/2 + zip_d;

difference() {

hull() {

translate([zip_s/2,-(zy+zip_w/2),0]) cylinder(h=wall_t, r=2);

translate([-zip_s/2,-(zy+zip_w/2),0]) cylinder(h=wall_t, r=2);

translate([-(hx/2 -2),-(hy/2),0])cylinder(h=wall_t, r=2);

translate([(hx/2 -2),-(hy/2),0])cylinder(h=wall_t, r=2);

translate([zip_s/2,(zy+zip_w/2),0]) cylinder(h=wall_t, r=2);

translate([-zip_s/2,(zy+zip_w/2),0]) cylinder(h=wall_t, r=2);

translate([-(hx/2 -2),(hy/2),0])cylinder(h=wall_t, r=2);

translate([(hx/2 -2),(hy/2),0])cylinder(h=wall_t, r=2);

}

//holes for zip ties

translate([zip_s/2, -zy, 0]) cube([zip_t, zip_w, wall_t*3], true);

translate([-zip_s/2, -zy, 0]) cube([zip_t, zip_w, wall_t*3], true);

translate([zip_s/2, zy, 0]) cube([zip_t, zip_w, wall_t*3], true);

translate([-zip_s/2, zy, 0]) cube([zip_t, zip_w, wall_t*3], true);

}

}