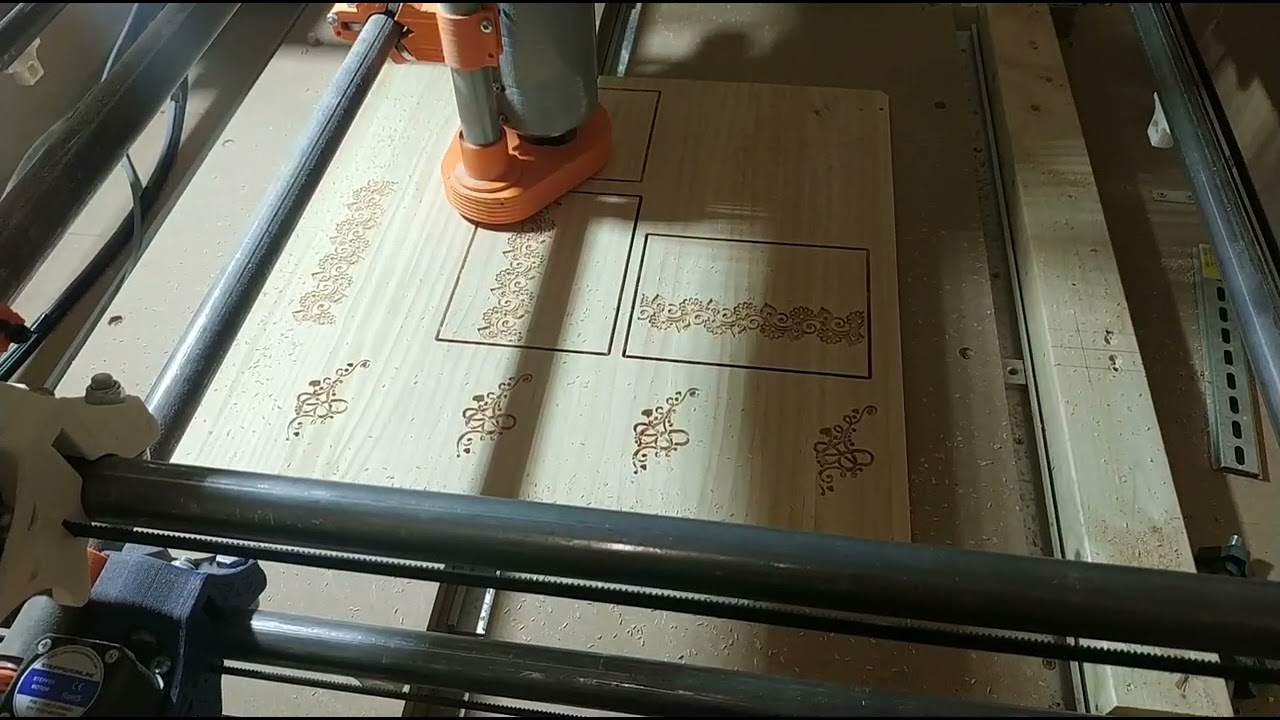

Before I built the lowrider/MPCNC concoction, I used the MPCNC to learn how a CNC works etc. I was abit too taken away by @jamiek tower monstrosity (said with admiration) and ended up having a two tier MPCNC for a while, one MPCNC sat on another (so the weight was on both tiers, and a total of 8 NEMA 17s and a NEMA 23 for the Z axis. Thought I’d share it just for a chuckle.

Wish I ran it for longer and put it more to the test, but wanted something for full sheets.

@BingBadaBoom , I’m not seeing any images for some reason. Are you seeing them on your end?

Same here!

I edited them. They were YT iframes, but also had some weird link. IDK why that didn’t work, but just pasting the youtube url will make the forum software embed them.

That’s double Primo! Mine is double Burly…

Thank you for that.

Video is too short. Cant really see what is going on. Jaime, are you referring to the idex build or something else?

I’ll see if I have anything else.

I was using a 2.2kw 80mm water cooler spindle. With a standard build it was easy cause to deflection.

Throwing another primo ontop meant that that there two cores and thus two sets of motors holding the spindle and it worked very well. Used the same idea for the 8x4 MPCNC/lowrider concoction I have used for the last year.

I was comparing to this one of mine:

https://forum.v1e.com/t/double-decker-build/10790

So was there something that made you make that? Was there something that just one tier was not accomplishing? What a task to true that up!!! Bravo. (Cannot believe I have been all over this site and still have treasures out there I have not seen yet!)

It had been said that tilting of the Z axis away from vertical is one of the weak points, which means that the Z height must be relatively short. If the Z stick-out doubles, the stiffness against tilting drops by 4x, so large Z working depth is not feasible.

By grabbing the far end (top end) of the Z axis and holding it in place, the Z axis can’t tilt anymore, provided the Z tubes are stiff enough. Then I can make an unreasonably large Z working depth without suffering poor stiffness.

I would say it has been a success, allowing me unreasonable Z height with stiffness that’s on par with a regular short machine. Or so I claim, without quantitative evidence. (yet!)

I await your next exciting adventure! I wish you were in michigan! Would love to visit!

Very interesting. Just surprised that in all the time I’ve scrolled through old post looking for ideas, that i haven’t come across this.

Question for you…

How are you driving the 8 nema17 motors? Are they in series for each axis?

Yes, all four X motors and all four Y motors are driven in series. I am using a 24V power supply so the top speed for four motors should be comparable to two motors at 12V.

To square the system I have stop blocks and I crash into -X and -Y hard stops. I have four hard stops for X and four hard stops for Y (one for each motor). Ordinarily this squares X and Y but in my case it also squares Z/X and Z/Y.