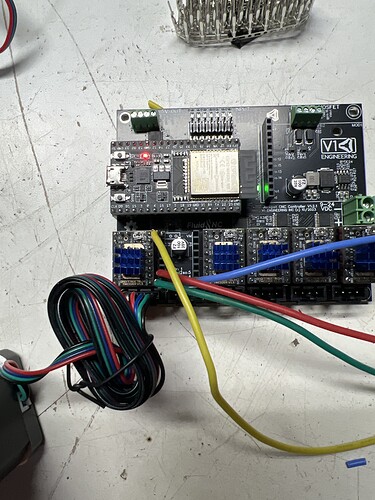

- This controller is designed for use with TMC2209 drivers in UART control mode only

Is this driver the limitation or the control mode?

I wand to add a rotary axis using a DQ860MA microstep driver from Wantai.

Can I just wire this into the Jackpot cnc controller board in the store?

If you’re not comfortable with landing wires into the header positions to take to your external stepper driver, or if you are not comfortable with editing a config file for those external steppers then you may find this difficult.

If you are comfortable and willing to ask for help and document your efforts in forum posts here, then you might find the Jackpot workable for you.

The jackpot is a derivative design of the Bart Dring series of ESP32 FluidNC controllers. Jackpot is configured for the way that V1 CNC machines are typically built. You could in theory use any stepper driver setup that is supported by FluidNC, which does include external stepper drivers.

I haven’t ever used the DQ860MA series external drivers, but at first glance they do look like they would work with FluidNC.

There is some work to do to enable that use, however- so depending on your level of comfort in wiring things up and edit the config files, you may or may not want to attempt it.

A board like the Bart Dring 6-pack controller might be a better fit for you if you’re not comfortable with the work to do the wiring and configuring.

It is possible to wire an external driver to the sockets where the TMC2209s would be installed.

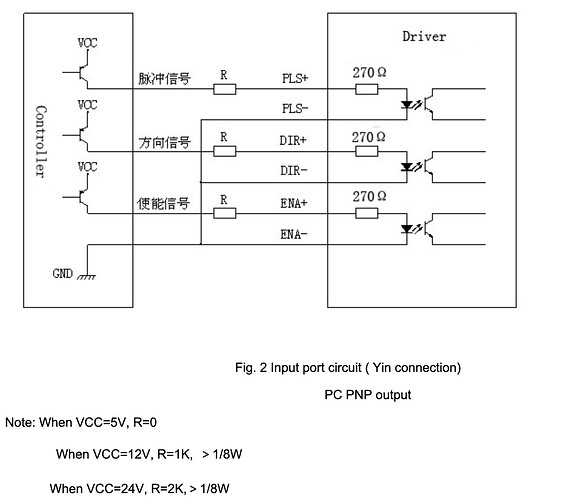

There appears to be some documentation on your drivers here:

https://www.hobby-machinist.com/attachments/dq860ma-manual-pdf.105753/

And in there is a connection diagram that looks at first glance like it could be supported by the STEP/DIR/ENABLE interface

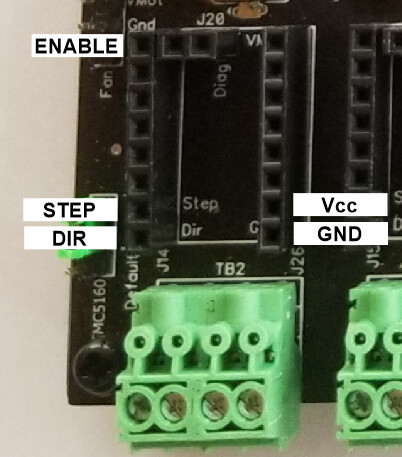

There’s some documentation about how that is done on the Bart Dring 6-pack located at;

And specifically an example shown at that site of where the wiring for an external stepper would land.

The jackpot board would be similar.

I got the external stepper to work! Didn’t do anything with the VCC port.

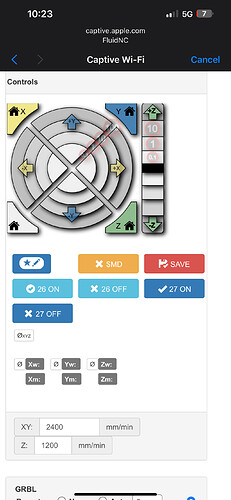

But now, how to operate the “A” axis. On the board it’d be “C” the last open spot while running the MPCNC. Here is the mobile version of the operating menu. It was identical on my laptop.

For my rotary I made a second config file. I commented out the Y axis and I redefined the Y axis using the C driver. When I’m done with the rotary, I just change back to my standard config.

It’s working, so I haven’t messed with it. (I have a personality flaw that sometimes causes me to fix something until it doesn’t work anymore.)

I worry because I do seem to get some low holding current in my Y motors, even after I’ve switched to rotary. They don’t get hot, and they hold position well, so I haven’t really dug in. I keep meaning to try adding an A axis for the rotary so I don’t have to switch configs, but then I remember its working and I try to resist fixing it.